Copper-based brazing filler metal with gradually-changing coefficient of thermal expansion and preparing method of copper-based brazing filler metal

A technology of thermal expansion coefficient and copper-based solder, which is used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of large residual stress in brazing joints, unstable brazing performance, and low strength of silver-based solder. Achieve the effect of reducing residual stress of joints, optimizing microstructure and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

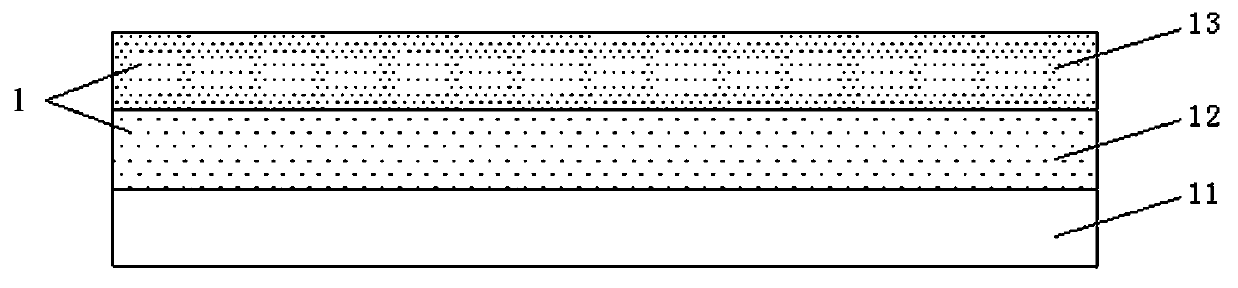

[0040] A copper-based solder with a gradient thermal expansion coefficient includes 72 parts by weight of metal powder, 27 parts of thermal expansion coefficient adjustment powder, 0.2 part of active agent and 0.8 part of dispersant. The active agent is a mixture of at least two of boron, borax, boric anhydride, potassium fluoride and potassium fluoroborate, and the dispersant is a silane coupling agent, polyethyleneimine, sodium lauryl sulfate, hexadecyl At least one of alkyltrimethylammonium bromide and polyoxyethylene monoacrylate.

[0041] Specifically, the metal powder includes 5 parts of tin, 5 parts of titanium, 5.5 parts of phosphorus, 5 parts of cobalt, 1 part of zinc, 1 part of indium, 1 part of manganese, 0.2 parts of silicon, 0.1 part of cerium and the balance of copper; The coefficient of thermal expansion adjusting powder includes 8 parts of nickel-coated titanium carbide, 60 parts of nickel-coated molybdenum and 32 parts of nickel-coated tungsten in parts by wei...

Embodiment 2

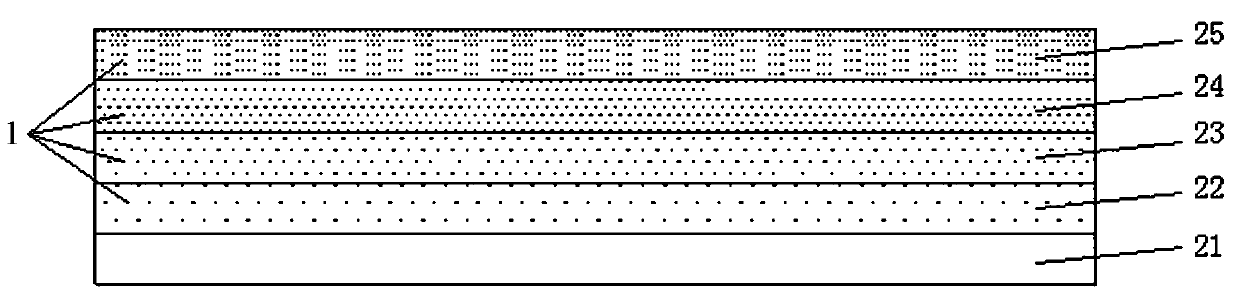

[0054] A copper-based solder with a gradient thermal expansion coefficient includes 72 parts by weight of metal powder, 27 parts of thermal expansion coefficient adjustment powder, 0.2 part of active agent and 0.8 part of dispersant. The active agent is a mixture of boron, borax, boric anhydride, potassium fluoride and potassium fluoroborate, and the dispersant is a silane coupling agent, polyethyleneimine, sodium lauryl sulfate, cetyl trimethyl at least one of ammonium bromide and polyoxyethylene monoacrylate.

[0055] The metal powder includes 5 parts of tin, 5 parts of titanium, 5.5 parts of phosphorus, 5 parts of cobalt, 1 part of zinc, 1 part of indium, 1 part of manganese, 0.2 parts of silicon, 0.1 part of cerium and the balance of copper; the thermal expansion coefficient is adjusted The powder includes 8 parts by weight of nickel-coated titanium carbide, 60 parts of nickel-coated molybdenum and 32 parts of nickel-coated tungsten. The particle size of the metal powder ...

Embodiment 3

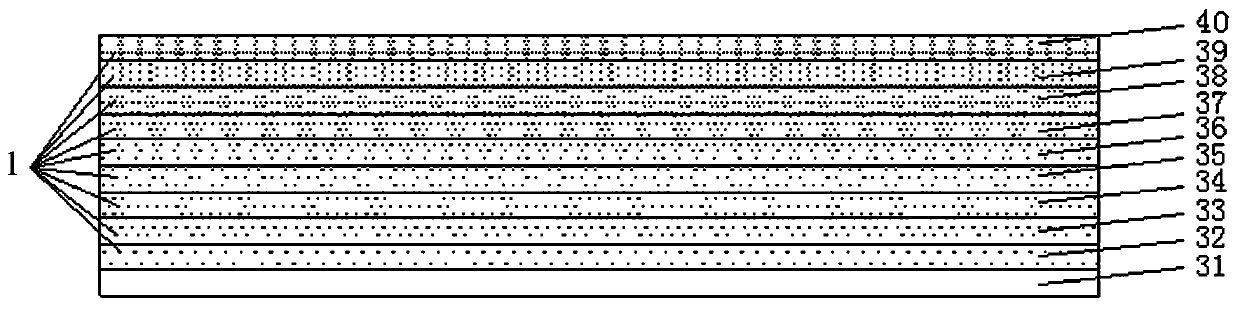

[0068] A copper-based solder with a gradient thermal expansion coefficient includes 72 parts by weight of metal powder, 27 parts of thermal expansion coefficient adjustment powder, 0.2 part of active agent and 0.8 part of dispersant. The active agent is a mixture of boron, borax, boric anhydride, potassium fluoride and potassium fluoroborate, and the dispersant is a silane coupling agent, polyethyleneimine, sodium lauryl sulfate, cetyl trimethyl at least one of ammonium bromide and polyoxyethylene monoacrylate.

[0069] Specifically, the metal powder includes 5 parts of tin, 5 parts of titanium, 5.5 parts of phosphorus, 5 parts of cobalt, 1 part of zinc, 1 part of indium, 1 part of manganese, 0.2 parts of silicon, 0.1 part of cerium and the balance of copper; The coefficient of thermal expansion adjusting powder includes 8 parts by weight of nickel-coated titanium carbide, 60 parts of nickel-coated molybdenum and 32 parts of nickel-coated tungsten. The particle size of the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com