Ecotypic cementing material

A cementitious material and ecological technology, applied in the direction of cement production, etc., can solve the problems of little research on cementitious materials, achieve significant social and economic benefits, easy access to production raw materials, and broad prospects for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The ratio of the cementitious material is: 55 parts of construction waste brick powder, 25 parts of slag, 10 parts of desulfurized ash, and 10 parts of compound grinding aid activator; the proportion of compound grinding aid activator is: 75 parts of calcined modified desulfurized gypsum, 10 parts of sodium metasilicate pentahydrate, 10 parts of sodium aluminate, 4.7 parts of naphthalene-based water reducer, 0.2 part of triethanolamine, 0.05 part of potassium humate, and 0.05 part of glycerol.

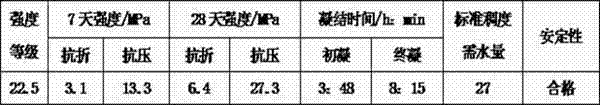

[0024] The materials are measured and ground to make cementitious materials, and the relevant performance indicators of the tested cementitious materials are shown in the following table:

[0025]

Embodiment 2

[0027] The ratio of the cementitious material is: 60 parts of construction waste brick powder, 15 parts of slag, 13% of desulfurization ash, 12 parts of compound grinding aid activator; the proportion of compound grinding aid activator is: 80 parts of calcined modified desulfurized gypsum, 8 parts of sodium metasilicate pentahydrate, 7 parts of sodium aluminate, 4.7 parts of naphthalene-based or polycarboxylate superplasticizer, 0.2 part of triethanolamine, 0.05 part of potassium humate, and 0.05 part of glycerin.

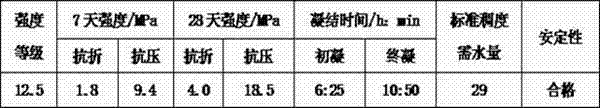

[0028] The materials are measured and ground to make cementitious materials, and the relevant performance indicators of the tested cementitious materials are shown in the following table:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com