Self-compacting non-contract concrete used in large-span CFST (Concrete Filled Steel Tube) arch bridge tube

A large-span, self-compacting technology, applied in the direction of arch bridges, bridges, bridge forms, etc., can solve the problems of damage, slow mixing flow rate, etc., achieve low viscosity, increase viscous resistance, and improve the effect of voiding phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

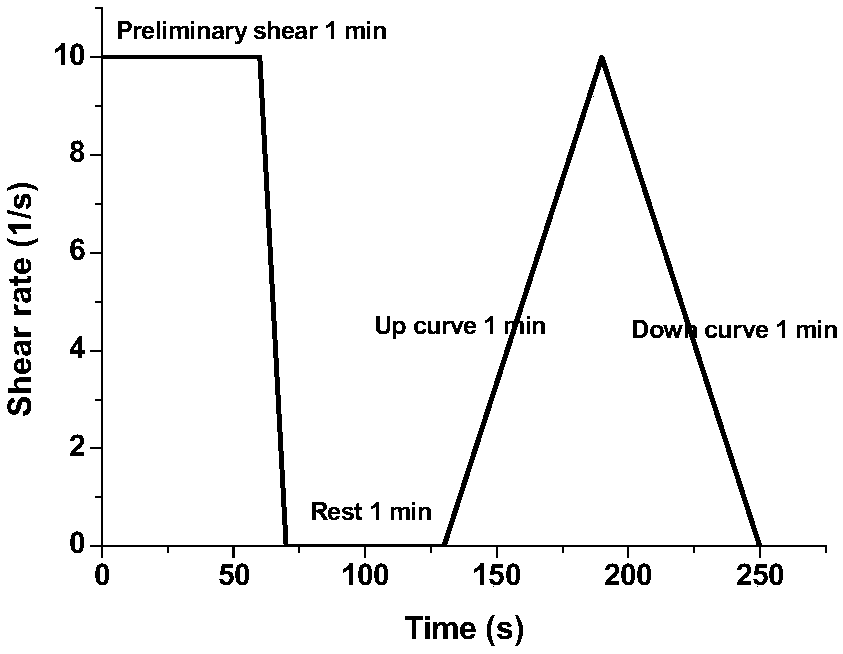

Method used

Image

Examples

Embodiment 1

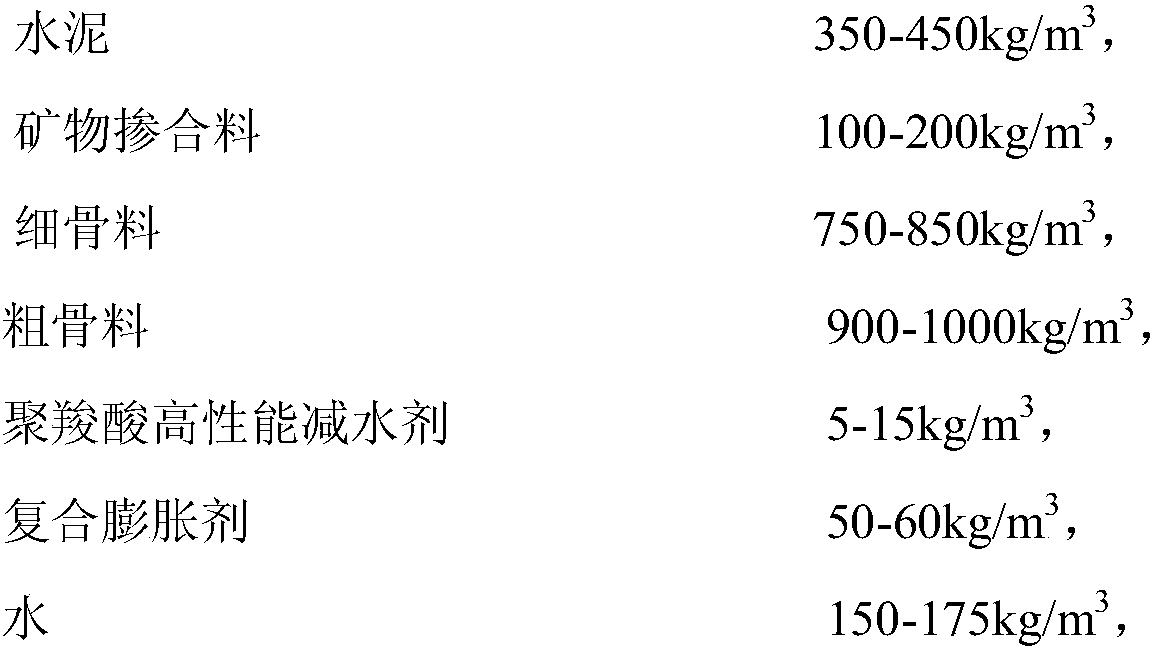

[0042] P.O42.5 cement 400kg / m 3 , fly ash 70kg / m 3 , mineral powder 35kg / m 3 , medium river sand 780kg / m 3 , gravel 940kg / m 3 , PCA-I polycarboxylate high-performance water reducer 11kg / m 3 , HME-II high-performance concrete magnesium oxide composite expansion agent 55kg / m 3 , water 165kg / m 3 .

Embodiment 2

[0044] P.II52.5 cement 350kg / m 3 , fly ash 105kg / m 3 , mineral powder 50kg / m 3 , medium river sand 780kg / m 3 , gravel 940kg / m 3 , PCA-I polycarboxylate high-performance water reducer 9kg / m 3 , HME-II high-performance concrete magnesium oxide composite expansion agent 55kg / m 3 , water 170kg / m 3 .

Embodiment 3

[0046] P.O52.5 cement 370kg / m 3 , fly ash 70kg / m 3 , mineral powder 30kg / m 3 , medium river sand 840kg / m 3 , gravel 935kg / m 3 , PCA-I polycarboxylate high-performance water reducer 10kg / m 3 , HME-II high-performance concrete magnesium oxide composite expansion agent 50kg / m 3 , water 153kg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com