Strontium-barium cement calcination composite mineralizer

A mineralizer and cement technology, applied in cement production, clinker production, etc., can solve the problems of storing waste slag occupying farmland, affecting the surrounding environment, and corroding production equipment, so as to shorten the firing time, increase kiln output, and reduce The effect of cement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The strontium barium cement calcined composite mineralizer of the present invention is applied to the process of manufacturing Portland cement, and the specific implementation and effects are as follows.

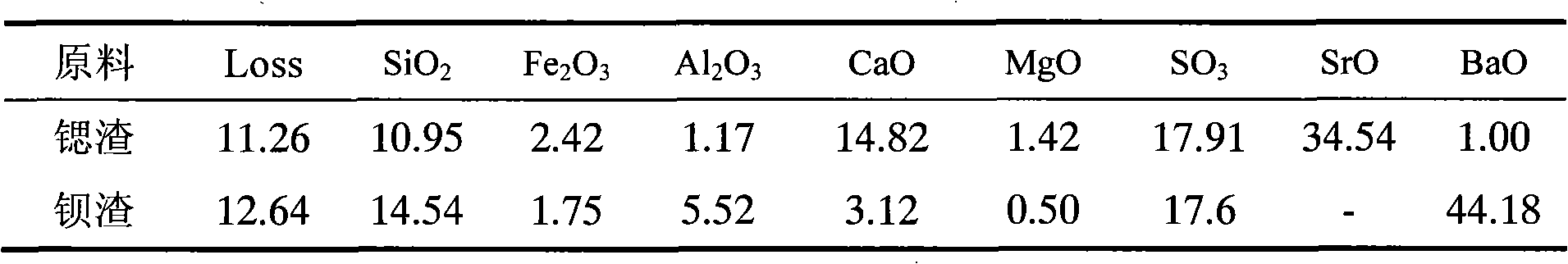

[0029] 1. The chemical components of strontium slag and barium slag used in the examples are shown in Table 1. Of course, the strontium slag and barium slag of the present invention are not limited to the following chemical components.

[0030] Table 1: Chemical composition of strontium slag and barium slag

[0031]

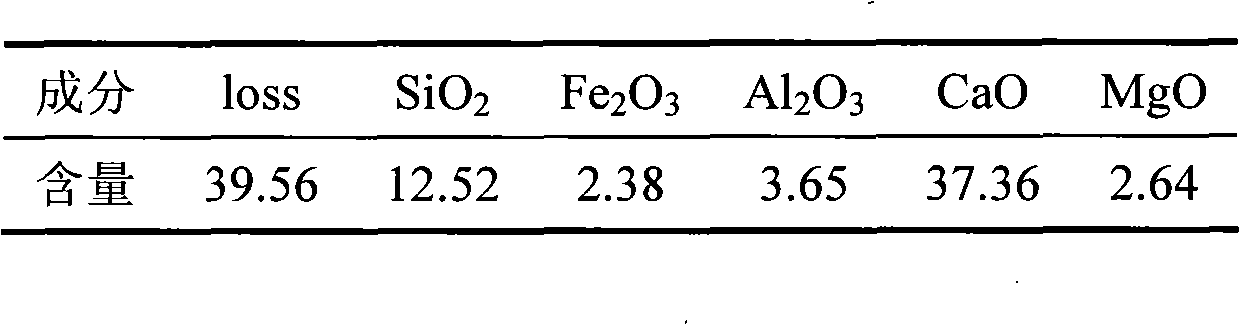

[0032] 2. The chemical components of cement raw meal and clinker used in the examples are shown in Table 2 and Table 3.

[0033] Table 2: Chemical composition of raw meal w%

[0034]

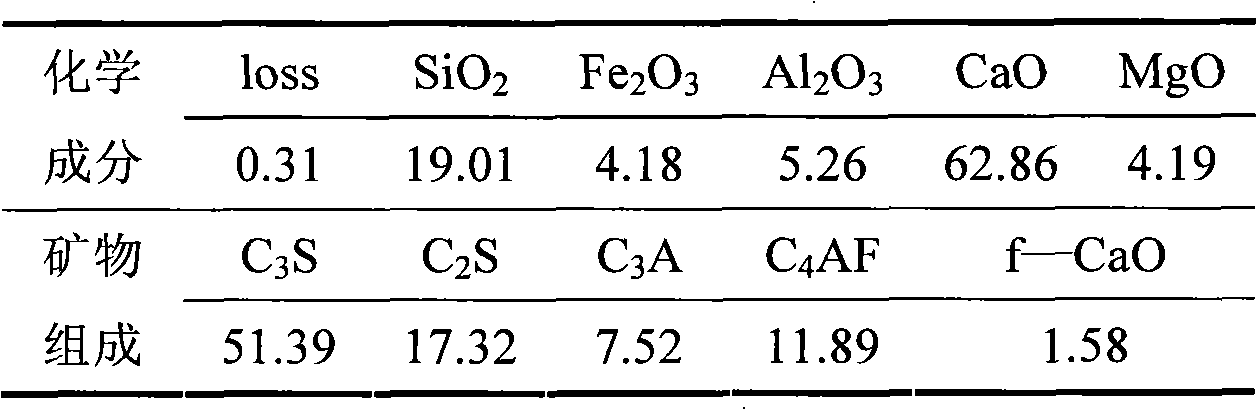

[0035] Table 3: Chemical composition and mineral composition of clinker w%

[0036]

[0037] 3. The implementation effect is shown in Table 4.

[0038] Table 4: Experimental data

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com