Formula for producing post porcelain insulator by using industrial alumina powder instead of high-quality alumina powder by dry method and preparation method and application thereof

A pillar porcelain insulator and industrial alumina technology, applied in the field of insulators, can solve problems such as large internal stress, high firing temperature, and difficult molding, and achieve the effects of small strength dispersion, complete fuel combustion, and good whiteness of the porcelain body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

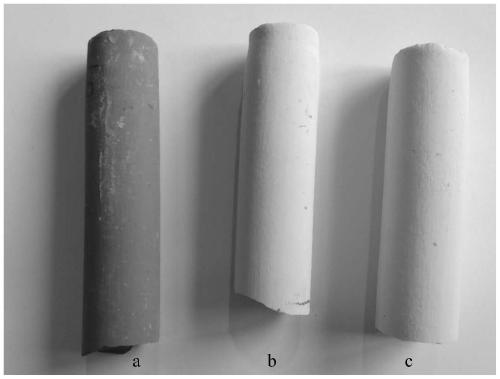

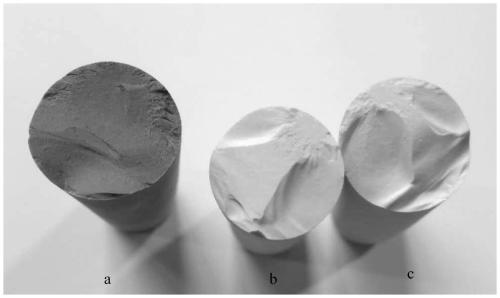

Image

Examples

Embodiment 1

[0036] Table 1 Preparation of porcelain insulator formula

[0037]

[0038] The preparation process of the porcelain insulator is as follows:

[0039] (1) Prepare the raw materials according to the formula in Table 1. Weigh industrial alumina powder, kaolin, feldspar, scouring soil, barium carbonate and 9300 according to weight percentages, and add them to the ball mill in order, set the milling time to 11h, and continue the milling;

[0040] (2) After passing the particle size test, sieving and grinding;

[0041] (3) After removing iron from the new slurry, it is spray-dried to make powder through ion high-speed atomization granulation equipment, and transported to the silo for aging for 24 hours;

[0042] (4) The stale powder is pressed into a blank by a large-scale dry cold isostatic press. The blank pressing curve is: 0~30MPa, 4min; 30MPa holding pressure for 1min; 30~60MPa, 2min; 60MPa , Pressure holding 1min; 60~105MPa, 2min; 105MPa pressure holding 1min; 105~60MPa, 2min; 60MPa ...

Embodiment 2

[0053] Table 3 Preparation of porcelain insulator formula

[0054]

[0055] The preparation process of the porcelain insulator is as follows:

[0056] (1) Prepare the raw materials according to the formula in Table 3. Weigh industrial alumina powder, kaolin, feldspar, Jingyang soil, scouring soil, barium carbonate, talc and PC-64 according to weight percentages, and add them to the ball mill in order, set the milling time to 11.5h, and continue the milling ;

[0057] (2) After passing the particle size test, sieving and grinding;

[0058] (3) After removing the iron from the new slurry, it is spray-dried to make powder through the high-speed ion atomization granulation equipment, and transported to the silo for 22 hours;

[0059] (4) The stale powder is pressed into a blank by a large-scale dry-process cold isostatic press; the blank pressing curve is: 0~30MPa, 4min; 30MPa holding pressure for 1min; 30~60MPa, 2min; 60MPa , Pressure holding 1min; 60~105MPa, 2min; 105MPa pressure holdi...

Embodiment 3

[0070] Table 5 Preparation of porcelain insulator formula

[0071]

[0072] The preparation process of the porcelain insulator is as follows:

[0073] (1) Prepare the raw materials according to the formula in Table 5. Weigh industrial alumina powder, kaolin, feldspar, scouring soil, barium carbonate and 9300 according to weight percentages, and add them to the ball mill in order, set the milling time to 11.5h, and continue the milling;

[0074] (2) After passing the particle size test, sieving and grinding;

[0075] (3) After removing the iron from the new slurry, it is spray-dried into powder through the high-speed ion atomization granulation equipment, and transported to the silo for aging for 24 hours;

[0076] (4) The stale powder is pressed into a blank by a large-scale dry-process cold isostatic press; the blank pressing curve is: 0~30MPa, 4min; 30MPa holding pressure for 1min; 30~60MPa, 2min; 60MPa , Pressure holding 1min; 60~105MPa, 2min; 105MPa pressure holding 2min; 105~60MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com