Multifunctional expandable fiber anti-cracking waterproof agent and preparation method

A technology of anti-cracking and waterproofing agent and swelling fiber, which is applied in the field of multi-functional expanding fiber anti-cracking and waterproofing agent and its preparation, can solve the problems of waterproofing, cracking resistance and unsatisfactory expansion performance, and achieve low cost, easy-to-obtain raw materials, and anti-cracking properties. strong cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] B2, preparation of oxidation catalyst: mix potassium dichromate and potassium manganate in a weight ratio of 2:1 to obtain a mixed oxidant; mix ammonium chloride and sodium chloride in a weight ratio of 2:3 to obtain a mixing accelerator agent;

[0039] B3. Take another sodium isobutylnaphthalene sulfonate, mix the mixed iron powder, mixed oxidant, mixing accelerator, and sodium isobutylnaphthalene sulfonate in a weight ratio of 10:1:1:0.1 to obtain an iron powder expander .

[0040] (3) Preparation of modified polypropylene fiber

[0041]C1. Take potassium dichromate, concentrated sulfuric acid, and deionized water to make a solution in a weight ratio of 10:75:15, add polypropylene fiber, and heat it in a water bath at a temperature of 60-80°C and a stirring speed of 200-500r / min for 2- 4h, the intermediate product of modified polypropylene fiber was obtained;

[0042] C2. The intermediate product of modified polypropylene fiber is washed with deionized water, filte...

Embodiment 1~5 and comparative example 1~2

[0045] Calcium sulfoaluminate, calcium oxide, magnesium oxide, fly ash, iron powder expansion agent, modified sepiolite wool, modified polypropylene fiber, sodium methyl silicate in Examples 1-5 and Comparative Examples 1-2 , sodium fluorosilicate, polycarboxylate high-efficiency water reducer in parts by weight as shown in Table 1 below.

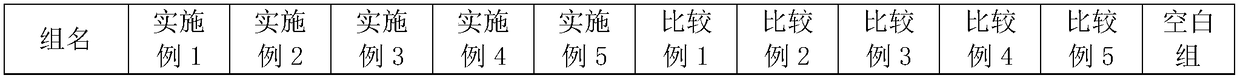

[0046] The parts by weight of the raw material of table 1 embodiment 1~5 and comparative example 1~2, unit: part

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com