Fire-retardant paint with steel structure

A technology of fire-resistant coatings and steel structures, applied in fire-resistant coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as rising production costs, weak anti-corrosion ability of steel, unaware of fire-proof performance, etc., and achieve fire-resistant time The effect of improving and improving the fire resistance limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

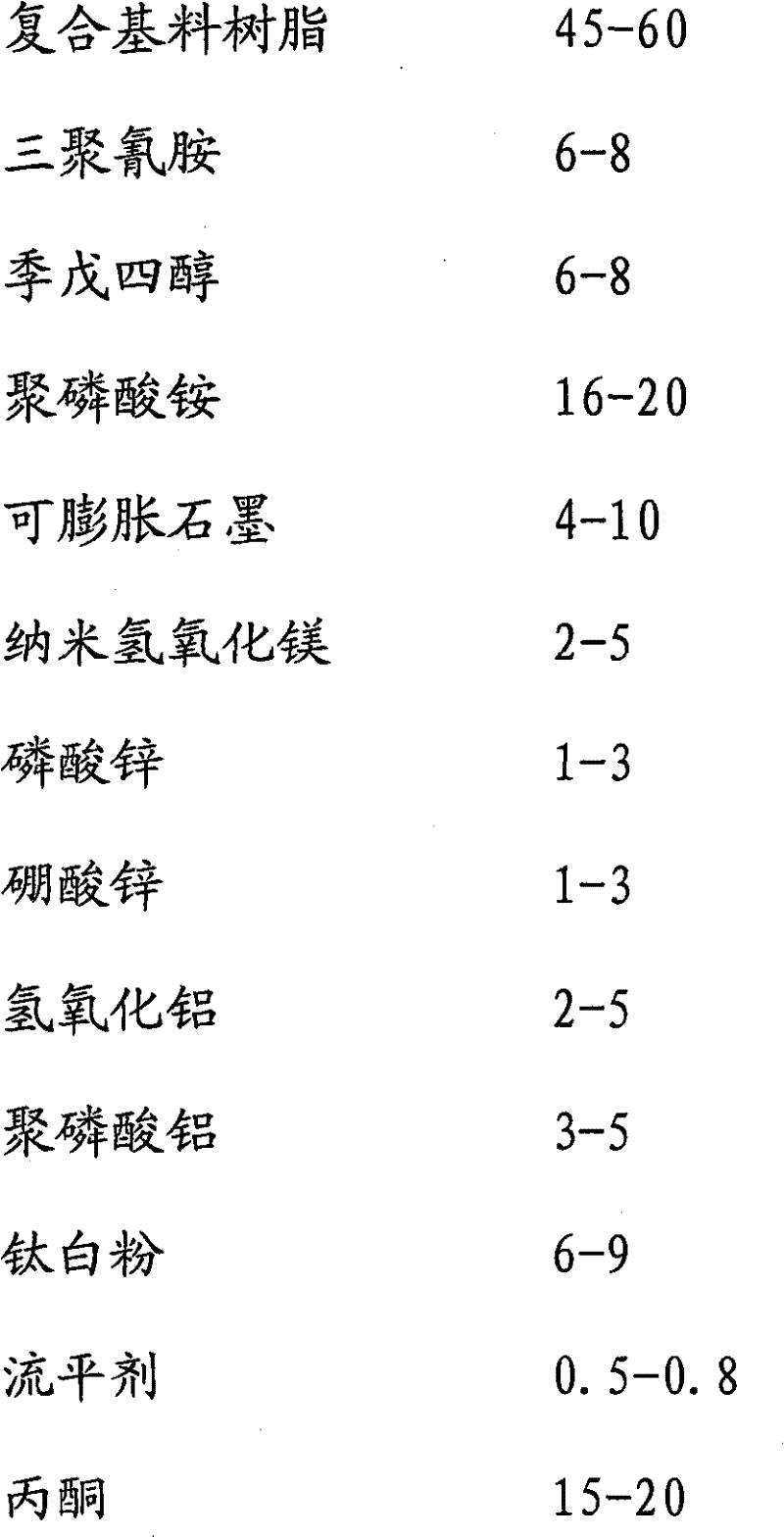

Method used

Image

Examples

Embodiment 1

[0039] Select the raw materials with the following weight ratio, acrylic resin 27, epoxy resin 9, polyurethane resin 9, melamine 6, pentaerythritol 6, ammonium polyphosphate 16, expandable graphite 4, nano magnesium hydroxide 2, zinc phosphate 1, zinc borate 1 , aluminum hydroxide 2, aluminum polyphosphate 3, titanium dioxide 6, leveling agent 0.5, acetone 15, first acrylic resin, epoxy resin, polyurethane resin, melamine, pentaerythritol, ammonium polyphosphate, expandable graphite, zinc phosphate, Zinc borate, aluminum hydroxide, aluminum polyphosphate, and titanium dioxide are crushed to make the particle size reach 700 mesh, and then the crushed particle raw materials are mixed with nano-magnesium hydroxide, leveling agent, and acetone, and then homogeneously dispersed at a high speed , to get paint.

[0040] The paint forms a 2mm coating on the steel structure material, and its fire resistance limit is determined to be 92 minutes.

Embodiment 2

[0042] Select the raw materials with the following weight ratio, acrylic resin 30, epoxy resin 10, polyurethane resin 10, melamine 7, pentaerythritol 8, ammonium polyphosphate 18, expandable graphite 7, nano magnesium hydroxide 3, zinc phosphate 2, zinc borate 2 , aluminum hydroxide 4, aluminum polyphosphate 4, titanium dioxide 7, leveling agent 0.7, acetone 16, first acrylic resin, epoxy resin, polyurethane resin, melamine, pentaerythritol, ammonium polyphosphate, expandable graphite, zinc phosphate, Zinc borate, aluminum hydroxide, aluminum polyphosphate, and titanium dioxide are crushed to make the particle size reach 700 mesh, and then the crushed particle raw materials are mixed with nano-magnesium hydroxide, leveling agent, and acetone, and then homogeneously dispersed at a high speed , to get paint.

[0043] The paint forms a 2mm coating on the steel structure material, and its fire resistance limit is determined to be 105 minutes.

Embodiment 3

[0045] Select the raw materials with the following weight ratio, acrylic resin 36, epoxy resin 12, polyurethane resin 12, melamine 8, pentaerythritol 8, ammonium polyphosphate 20, expandable graphite 9, nano magnesium hydroxide 3, zinc phosphate 3, zinc borate 3 , aluminum hydroxide 5, aluminum polyphosphate 4, titanium dioxide 7, leveling agent 0.7, acetone 20, first acrylic resin, epoxy resin, polyurethane resin, melamine, pentaerythritol, ammonium polyphosphate, expandable graphite, zinc phosphate, Zinc borate, aluminum hydroxide, aluminum polyphosphate, and titanium dioxide are crushed to make the particle size reach 700 mesh, and then the crushed particle raw materials are mixed with nano-magnesium hydroxide, leveling agent, and acetone, and then homogeneously dispersed at a high speed , to get paint.

[0046] The paint forms a 2mm coating on the steel structure material, and its fire resistance is determined to be 137 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com