Flame-retardant antibacterial fabric

A technology of antibacterial fabrics and flame-retardant fibers, which is applied in the manufacture of fire-resistant and flame-retardant filaments, plant fibers, and fiber treatment. It can solve the problems of fabric flame retardancy, poor antibacterial effect, and instability, and achieve enhanced antibacterial effects. Wide application , Improve the effect of insoluble in water and the limitations of spinning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

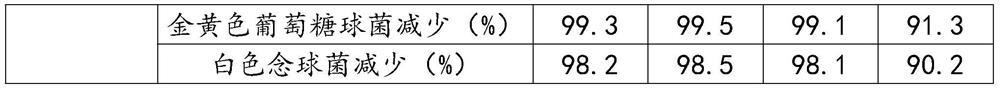

Examples

Embodiment 1

[0033] A flame-retardant and antibacterial fabric, comprising the following raw materials in parts by weight:

[0034] 60 parts of antibacterial and flame-retardant fiber, 30 parts of cotton fiber, 50 parts of sodium hydroxide solution with a mass fraction of 10%, 10 parts of fatty alcohol polyoxyethylene ether, 2 parts of nano-barium oxide, 100 parts of treatment liquid, and 10 parts of styling liquid;

[0035] The flame-retardant and antibacterial fabric is prepared through the following steps:

[0036] The first step is to interweave antibacterial and flame-retardant fibers and cotton fibers into gray cloth, soak the gray cloth with a solution made of 10% sodium hydroxide solution, fatty alcohol polyoxyethylene ether and nano-barium oxide, and raise the solution to Soak at 45°C for 15 minutes, then rise to 75°C for 5 minutes, and finally rise to 100°C for 10 minutes, then cool, first rise to 45°C for 15 minutes, then rise to 80°C for 10 minutes, and finally rise to 110°C for ...

Embodiment 2

[0053] A flame-retardant and antibacterial fabric, comprising the following raw materials in parts by weight:

[0054] 65 parts of antibacterial and flame-retardant fiber, 35 parts of cotton fiber, 60 parts of sodium hydroxide solution with a mass fraction of 11%, 11 parts of fatty alcohol polyoxyethylene ether, 3 parts of nano-barium oxide, 150 parts of treatment liquid, and 15 parts of styling liquid;

[0055] The flame-retardant and antibacterial fabric is prepared through the following steps:

[0056] The first step is to interweave antibacterial and flame-retardant fibers and cotton fibers into gray cloth, soak the gray cloth with a solution made of 11% sodium hydroxide solution, fatty alcohol polyoxyethylene ether and nano-barium oxide, and raise the solution to Soak at 48°C for 18 minutes, then rise to 80°C for 8 minutes, and finally rise to 110°C for 12 minutes, then cool, first rise to 45°C for 15 minutes, then rise to 80°C for 10 minutes, and finally rise to 110°C fo...

Embodiment 3

[0073] A flame-retardant and antibacterial fabric, comprising the following raw materials in parts by weight:

[0074] 70 parts of antibacterial and flame-retardant fiber, 40 parts of cotton fiber, 70 parts of sodium hydroxide solution with a mass fraction of 12%, 12 parts of fatty alcohol polyoxyethylene ether, 4 parts of nano-barium oxide, 200 parts of treatment liquid, and 20 parts of styling liquid;

[0075] The flame-retardant and antibacterial fabric is prepared through the following steps:

[0076] The first step is to interweave antibacterial and flame-retardant fibers and cotton fibers into gray cloth, soak the gray cloth with a solution made of 12% sodium hydroxide solution, fatty alcohol polyoxyethylene ether and nano-barium oxide, and raise the solution to Soak at 50°C for 20 minutes, then rise to 85°C for 10 minutes, and finally rise to 120°C for 15 minutes, then cool, first rise to 45°C for 15 minutes, then rise to 80°C for 10 minutes, and finally rise to 110°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com