Preparation method of sanitary nonwoven fabric for medical use

A non-woven and hygienic technology, which is applied in the direction of medical formula, medical science, dressings, etc., can solve the problems of poor hemostasis ability of non-woven wounds, slow down wound healing effect, reduce the air flow of non-woven fabrics, etc., and achieve improvement Antibacterial effect, effect to prevent excessive bleeding or infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

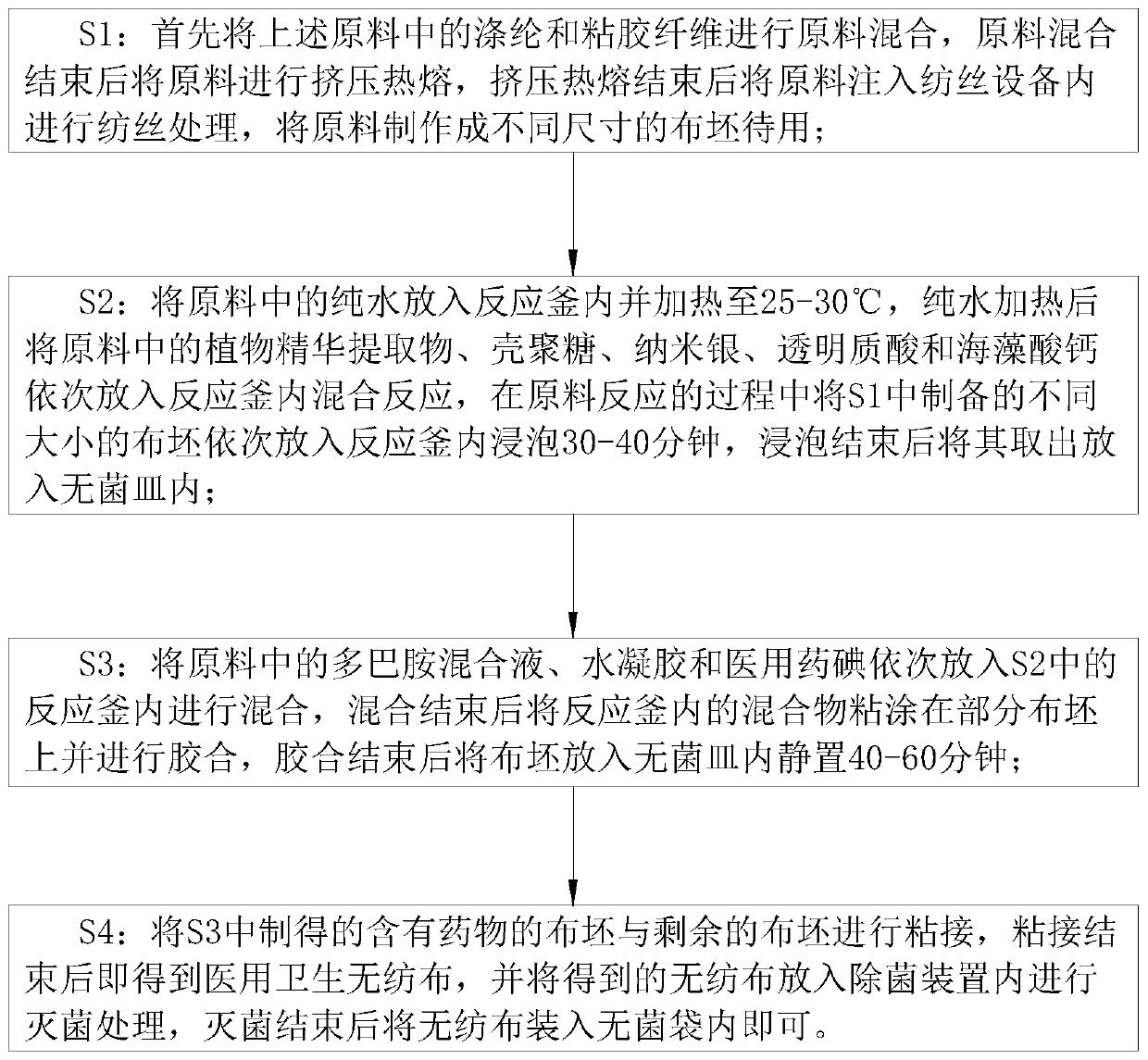

[0036] The preparation method of medical sanitary nonwoven fabric comprises the following steps:

[0037] S1: Firstly, the polyester and viscose fibers in the above raw materials are mixed. After the raw materials are mixed, the raw materials are extruded and melted. After the extrusion and melted, the raw materials are injected into the spinning equipment for spinning treatment. Cloths of different sizes are ready for use; by using the cloths made of the above raw materials, the prepared cloths can be made to have a skin-friendly effect, thereby preventing the cloths from polluting the skin wounds, and at the same time, the cloths are relatively soft and non-toxic scratches the skin;

[0038] S2: Put the pure water in the raw material into the reaction kettle and heat it to 25-30°C. After heating the pure water, put the plant essence extract, chitosan, nano-silver, hyaluronic acid and calcium alginate in the raw material in sequence. Put them into the reaction kettle for mix...

Embodiment approach

[0041] As an embodiment of the present invention, the raw materials also include polyvinylpyrrolidone and amino-terminated polyethylene glycol;

[0042] The polyvinylpyrrolidone used in the raw material is a kind of medicinal material, and has strong binding ability, can exist in the mode of binding agent in the present invention, also has strong stability and lubricity simultaneously, thus prevents The prepared dressing is easy to react with other substances to reduce the medical effect. At the same time, polyvinylpyrrolidone can also be combined with the dopamine mixture in the raw material to form a strong hydrogen bond, which can improve the firmness of the non-woven coating At the same time, polyvinylpyrrolidone can also complex with the iodine element in the raw material, thereby introducing the bactericidal group of the iodine element, and constructing a non-woven surface with anti-fouling and bactericidal synergistic effects. The amino-terminated polyethylene glycol ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com