Bio-based fire-resistant paper capable of resisting fire for 1200 seconds and preparation method

A bio-based, fire-resistant technology, applied in the field of papermaking, can solve the problems of flammability and fire resistance, books and paper documents burned, etc., and achieve the effect of improving fire resistance and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

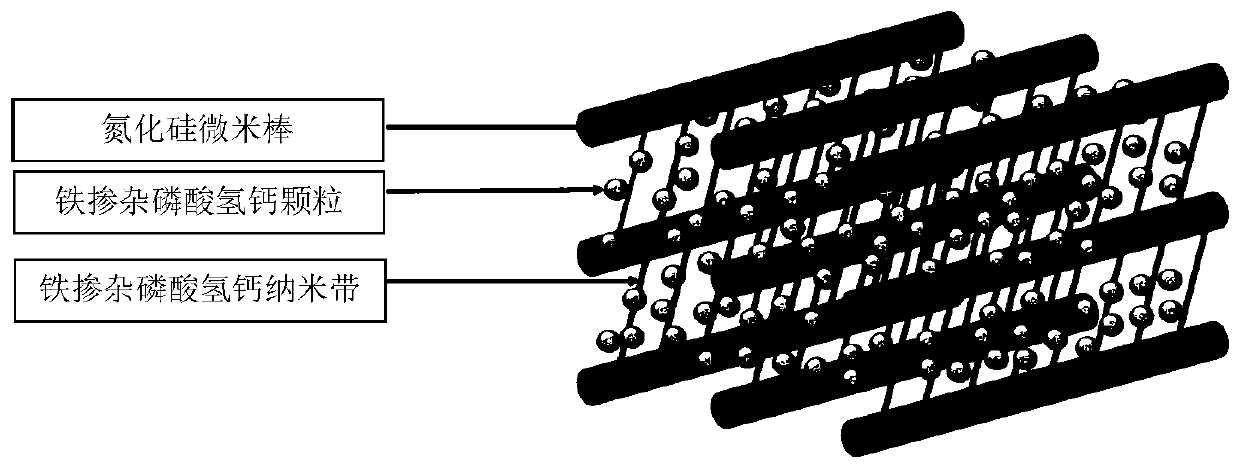

[0025] (1) Mix iron-doped calcium hydrogen phosphate nanobelts and iron-doped calcium hydrogen phosphate particles uniformly according to a mass ratio of 1:5 to obtain powder A;

[0026] (2) Mix polysilazane and xylene uniformly according to the volume ratio of 1:1 to obtain liquid B;

[0027] (3) Add powder A to liquid B, wherein the concentration of powder A is 10g / L, stir evenly to obtain solution C;

[0028] (4) Apply solution C evenly on the graphite paper along the same direction, then dry it at 40°C, then take it out and apply solution C evenly along the same direction again, then dry it again at 40°C, repeat the process The brush-drying process was carried out 6 times in total to obtain sample D;

[0029] (5) Place the sample D in a heat treatment furnace, and in a nitrogen-protected environment, raise the temperature to 230°C at a heating rate of 2°C / min, and keep it for 30 minutes, then raise the temperature to 1150°C at a heating rate of 2°C / min, and keep it warm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com