Refractory brick prepared on the basis of refractory material

A technology of refractory materials and refractory bricks, which is applied in the field of refractory bricks, can solve the problems of affecting the heat resistance of refractory bricks, poor connection stability, brick expansion and cracking, etc., so as to improve the use range, increase sealing performance, and alleviate brick expansion and cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

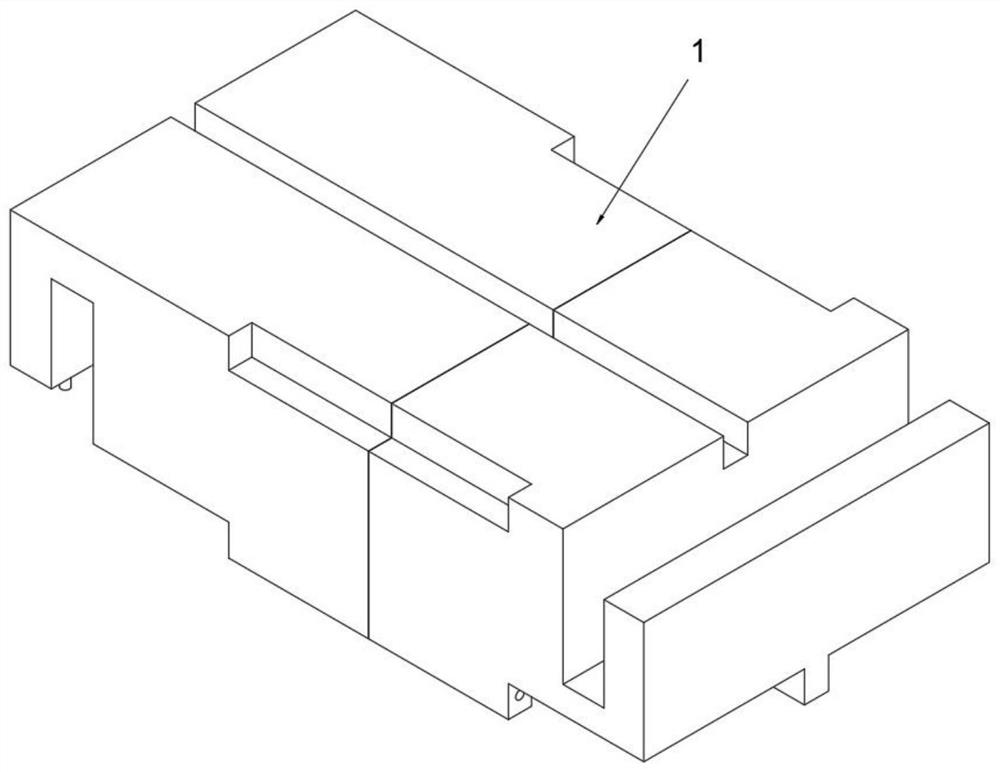

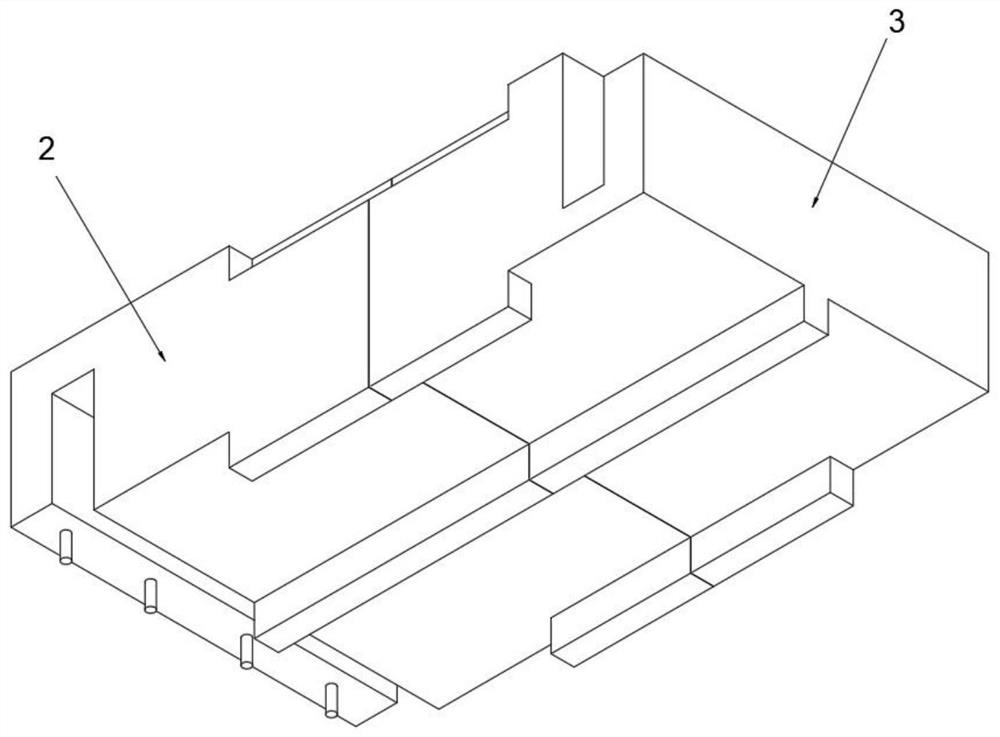

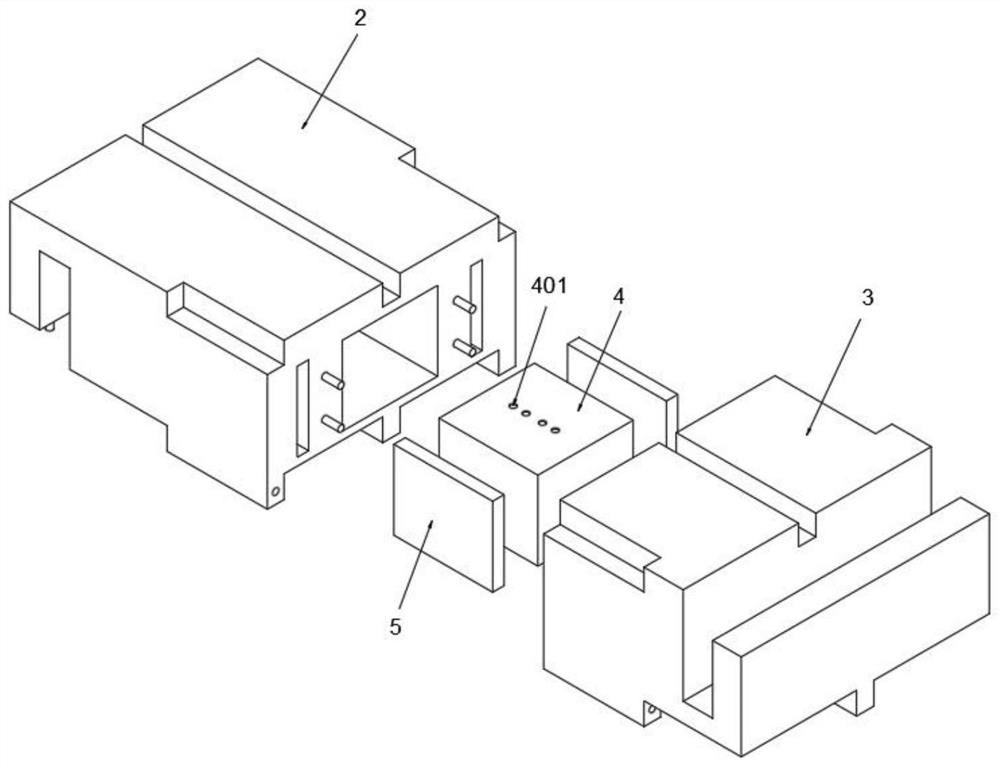

[0048] see Figure 1-Figure 14 As shown, the purpose of this embodiment is to provide a refractory brick prepared based on refractory materials, including a brick body 1 and a mother brick 2 and a sub-brick 3 arranged on the brick body 1;

[0049] The mother brick 2 includes at least a first housing 209, a first limiting groove 201 is opened at the center of the upper surface of the first housing 209, and a groove 2012 is opened on the upper surface of the first limiting groove 201 near the right edge, The upper surface of the first housing 209 is integrally formed with a first engaging wall 203 near the left edge, and the lower surface of the first engaging wall 203 is fixedly connected with a connecting rod 2032 . The first engaging wall 203 and the first housing 209 A lower groove 2031 is reserved between them, a first core groove 205 is opened at the center of the right side wall surface of the first housing 209, and a first heat insulation groove 206 is opened on the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com