Ultra-thin section steel structure weather-resistant fireproof paint, and preparation method thereof

A technology for fire-resistant coatings and steel structures, applied in the field of coatings, can solve the problems of poor weather resistance and increased use costs, and achieve the effects of improving strength and surface finish, improving weather resistance, and improving thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

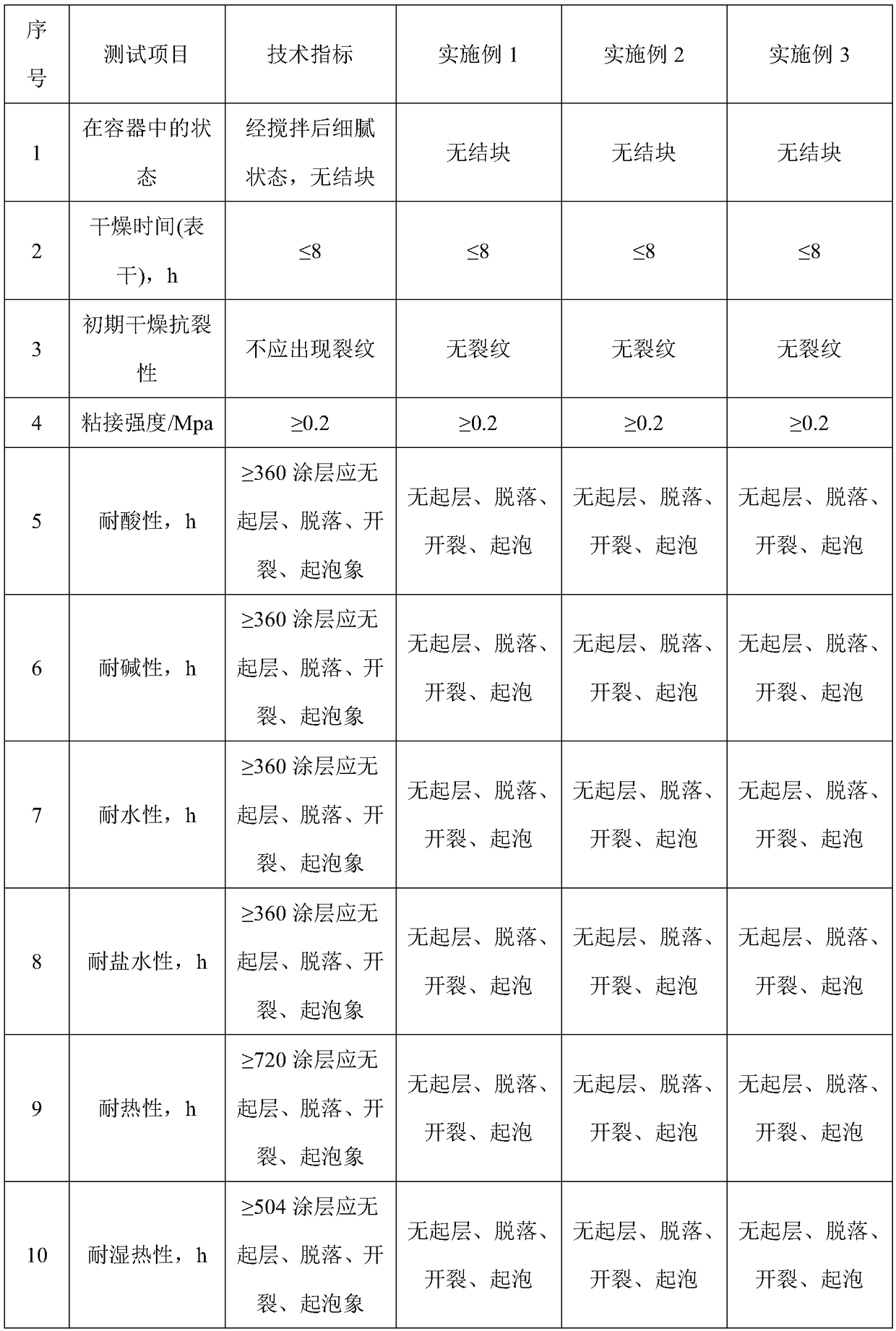

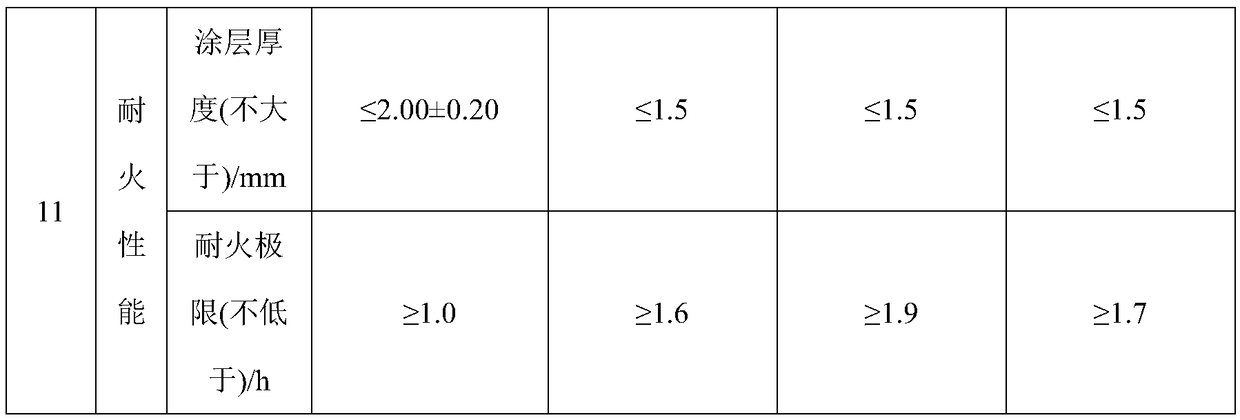

Examples

Embodiment 1

[0023] The ultra-thin weather-resistant fireproof coating for steel structures in this embodiment consists of the following parts by weight: 20 parts of modified acrylic resin, 10 parts of unsaturated polyester, 6 parts of alkyd resin, 10 parts of melamine phosphate, hydrated boric acid 5 parts of zinc, 5 parts of nano calcium carbonate, 7 parts of vermiculite, 25 parts of cyclohexanone, 4 parts of modified barium metaborate, 2.5 parts of bentonite, 2 parts of plasticizer, 1 part of leveling agent, 2 parts of ultraviolet absorber .

[0024] The modified acrylic resin is a silicone modified acrylic resin; the plasticizer is castor oil; the leveling agent is polydimethylsiloxane; the ultraviolet absorber is 2,4-dihydroxy di Benzophenone.

[0025] The preparation method of the above-mentioned ultra-thin steel structure weather-resistant fireproof coating comprises the following steps:

[0026] (1) Preparation of component A: completely mix the above-mentioned modified acrylic r...

Embodiment 2

[0030] The ultra-thin weather-resistant fireproof coating for steel structures in this embodiment consists of the following parts by weight: 25 parts of modified acrylic resin, 15 parts of unsaturated polyester, 10 parts of alkyd resin, 15 parts of melamine phosphate, hydrated boric acid 4 parts of zinc, 7 parts of nano calcium carbonate, 5 parts of vermiculite, 30 parts of cyclohexanone, 6 parts of modified barium metaborate, 2.5 parts of bentonite, 3 parts of plasticizer, 2 parts of leveling agent, 3 parts of ultraviolet absorber .

[0031] The modified acrylic resin is a silicone modified acrylic resin; the plasticizer is epoxy soybean oil; the leveling agent is a mixture of polydimethylsiloxane and polymethylphenylsiloxane ; The ultraviolet absorber is a mixture of phenyl o-hydroxybenzoate and resorcinol monobenzoate.

[0032] The preparation method of the above-mentioned ultra-thin steel structure weather-resistant fireproof coating comprises the following steps:

[003...

Embodiment 3

[0037] The ultra-thin weather-resistant fireproof coating for steel structures in this embodiment consists of the following parts by weight: 30 parts of modified acrylic resin, 18 parts of unsaturated polyester, 15 parts of alkyd resin, 20 parts of melamine phosphate, hydrated boric acid 7 parts of zinc, 10 parts of nano calcium carbonate, 3 parts of vermiculite, 35 parts of cyclohexanone, 3 parts of modified barium metaborate, 3 parts of bentonite, 1 part of plasticizer, 3 parts of leveling agent, 5 parts of ultraviolet absorber .

[0038]The modified acrylic resin is a silicone modified acrylic resin; the plasticizer is a mixture of castor oil and epoxy soybean oil; the leveling agent polymethylphenylsiloxane; the ultraviolet absorber It is a mixture of 2,4-dihydroxybenzophenone and phenyl o-hydroxybenzoate.

[0039] The preparation method of the above-mentioned thin steel structure weather-resistant fireproof coating comprises the following steps:

[0040] (1) Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com