Water-based heavy anti-corrosion flame-retardant coating material for metal base material, and preparation method thereof

A metal substrate, flame retardant coating technology, applied in anti-corrosion coatings, fire-retardant coatings, epoxy resin coatings, etc., can solve problems such as affecting the service life, and achieve the effect of prolonging the life of the coating, improving the dispersion, and reducing the shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

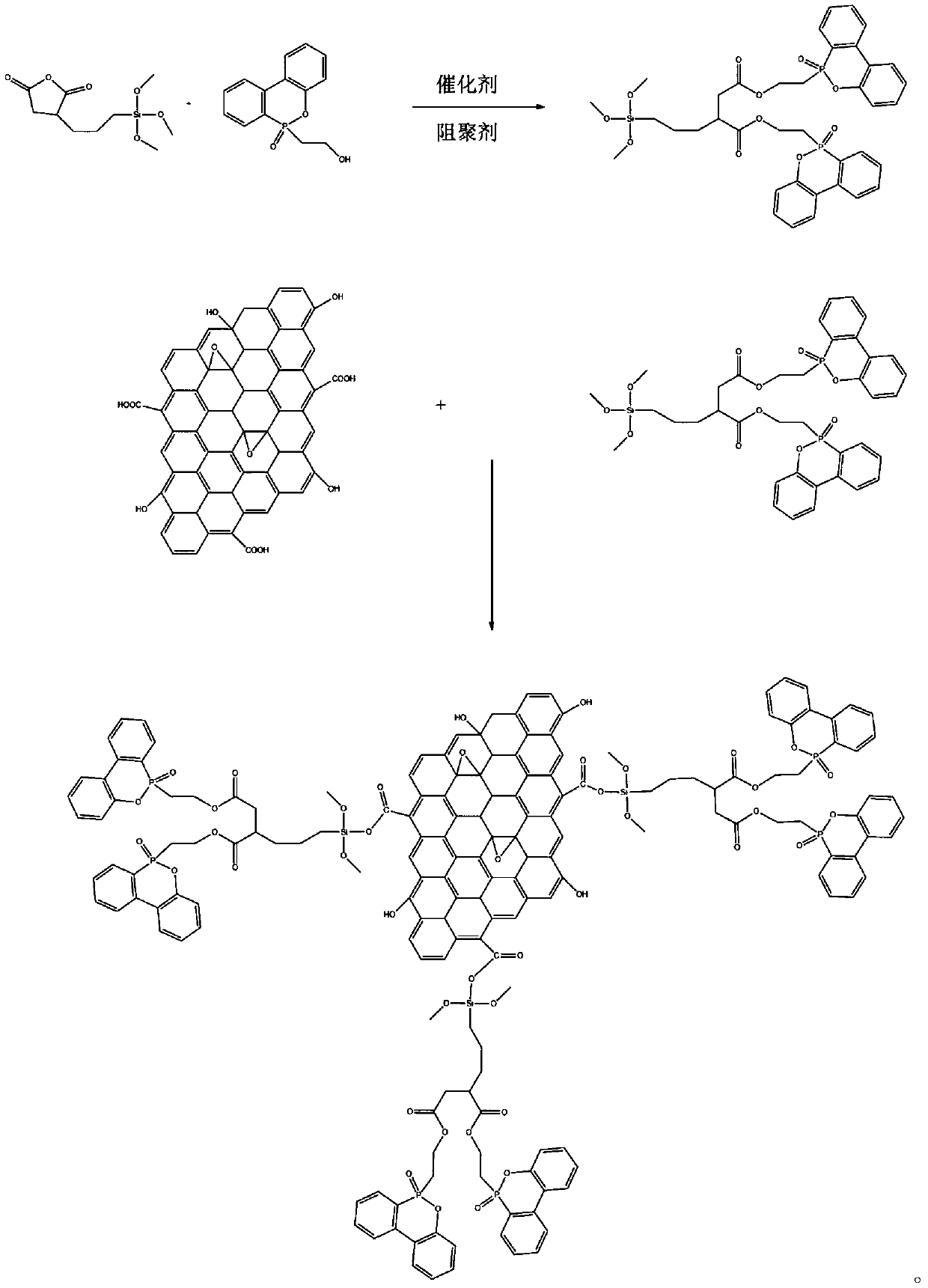

Method used

Image

Examples

Embodiment 1

[0042]A water-based heavy-duty anti-corrosion and flame-retardant coating for metal substrates, which is composed of A and B two components, and the weight ratio of the A component and the B component is 100:25;

[0043] Wherein, described component A is made up of following raw material by weight:

[0044] 55 parts of modified epoxy resin emulsions, 12 parts of functionalized modified graphene, 15 parts of mica powder, ethylene glycol ether and isopropanol by mass ratio of 1: 1 composition of 8 parts of co-solvent, 1 part of silicone defoamer, selected from BYK-1781 of BYK Chemicals, 0.8 parts of fluorine-modified acrylic polymer, selected from MOK-2024 of German Merck, modified polyurea 1.5 parts of N-methylpyrrolidone solution, selected from BYK-410 of BYK Chemicals, 1 part of propylene glycol, selected from Jinan Deying Chemical Co., Ltd., 1.5 parts of polyurethane thickener, selected from UH-752 of Japan Adike, 1.5 parts of polyoxyethylene alkylaryl ether, selected from ...

Embodiment 2

[0064] A water-based heavy-duty anti-corrosion and flame-retardant coating for metal substrates, which consists of two components, A and B, and the weight ratio of the A component to the B component is 100:20;

[0065] Wherein, described component A is made up of following raw material by weight:

[0066] 50 parts of modified epoxy resin emulsion, 10 parts of functionalized modified graphene, 12 parts of mica powder, ethylene glycol ether and isopropanol by mass ratio of 1: 1 composition of 5 parts of co-solvent, 0.8 parts of silicone defoamer, selected from BYK-1781 of BYK Chemicals, 0.5 parts of fluorine-modified acrylic polymer, selected from MOK-2024 of German Merck, modified polyurea 1 part of N-methylpyrrolidone solution, selected from BYK-410 of BYK Chemicals, 0.5 part of propylene glycol, selected from Jinan Deying Chemical Co., Ltd., 1 part of polyurethane thickener, selected from UH-752 of Japan Adico, 1 part of polyoxyethylene alkylaryl ether, selected from Jiangsu...

Embodiment 3

[0086] A water-based heavy-duty anti-corrosion and flame-retardant coating for metal substrates, which consists of two components, A and B, and the weight ratio of the A component to the B component is 100:30;

[0087] Wherein, described component A is made up of following raw material by weight:

[0088] 60 parts of modified epoxy resin emulsion, 15 parts of functionalized modified graphene, 18 parts of mica powder, ethylene glycol ether and isopropanol by mass ratio of 1: 10 parts of co-solvent, 0.5 parts of silicone defoamer, selected from BYK-1781 of BYK Chemicals, 1 part of fluorine-modified acrylic polymer, selected from MOK-2024 of German Merck, modified polyurea 2 parts of N-methylpyrrolidone solution, selected from BYK-410 of BYK Chemicals, 1 part of propylene glycol, selected from Jinan Deying Chemical Co., Ltd., 1.2 parts of polyurethane thickener, selected from UH-752 of Japan Adike, 2 parts of polyoxyethylene alkylaryl ether, selected from Jiangsu Haian Petrochem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com