Flame retardant coating for cars and preparation method thereof

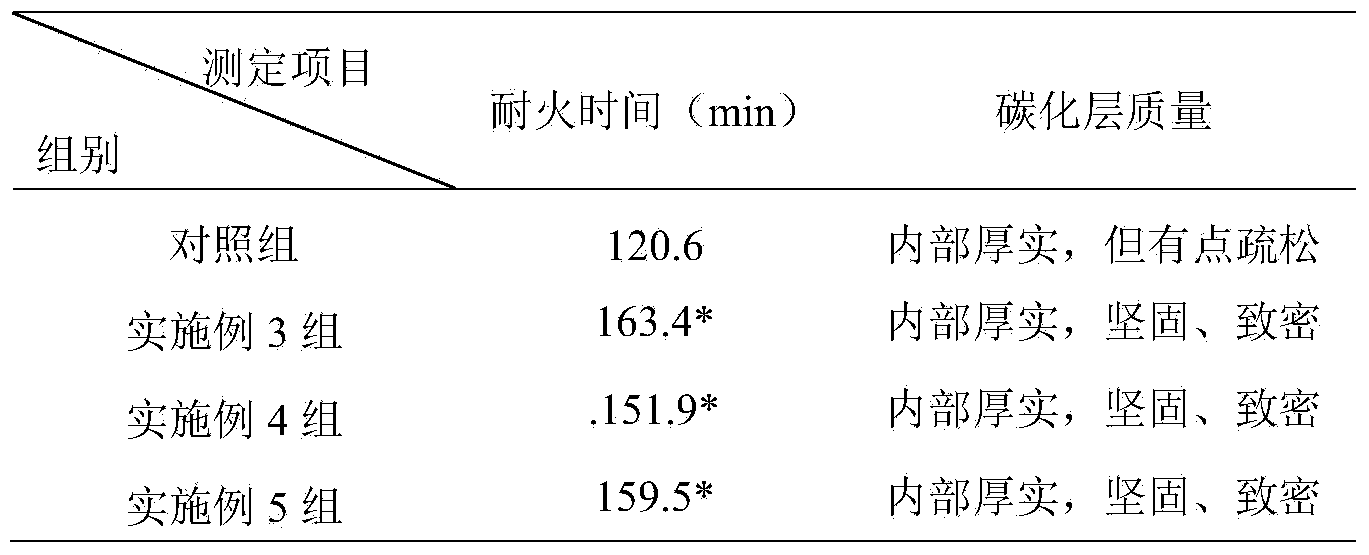

A coating and automotive technology, applied in fire-retardant coatings, polyester coatings, coatings, etc., can solve the problems of short fire resistance time and poor flame retardant effect, and achieve the effect of improved flame retardant effect, low VOC emission and thick interior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Party:

[0022] Hydroxy acrylic resin 20g, alkyd resin 10g, trimethylolpropane triacrylate 10g,

[0023] Etherified fluorocarbon resin 5g, melamine phosphate 5g, pentaerythritol 5g, diammonium hydrogen phosphate 5g, pigment 1g,

[0024] Glass powder 2g.

[0025] Preparation:

[0026] (1) Mix melamine phosphate and diammonium hydrogen phosphate, add glass powder and pigment during the stirring process, and disperse at a high speed of 3600 r / min for 30 minutes to obtain a color slurry;

[0027] (2) Make an emulsion of hydroxyacrylic resin, alkyd resin, trimethylolpropane triacrylate and etherified fluorocarbon resin, mix with pentaerythritol and the above-mentioned color paste, and disperse at a low speed of 800r / min for 20 minutes to obtain the product.

Embodiment 2

[0029] Party:

[0030] Hydroxy acrylic resin 20g, alkyd resin 30g, trimethylolpropane triacrylate 20g,

[0031] Etherified fluorocarbon resin 15g, melamine phosphate 20g, pentaerythritol 15g, urea phosphate 15g, pigment 5g,

[0032] Diatomaceous earth 8g.

[0033] Preparation:

[0034] (1) Mix melamine phosphate and urea phosphate, add diatomaceous earth and pigment during the stirring process, and disperse at a high speed of 4200 r / min for 20 minutes to obtain a color slurry;

[0035] (2) Make an emulsion of hydroxyacrylic resin, alkyd resin, trimethylolpropane triacrylate and etherified fluorocarbon resin, mix with pentaerythritol and the above-mentioned color paste, and disperse at a low speed of 1200r / min for 10 minutes.

Embodiment 3

[0037] Party:

[0038] Hydroxy acrylic resin 20g, alkyd resin 20g, trimethylolpropane triacrylate 15g,

[0039] Etherified fluorocarbon resin 10g, melamine phosphate 12.5g, pentaerythritol 10g, ammonium dihydrogen phosphate 10g,

[0040] Pigment 3g, perlite 5g.

[0041] Preparation:

[0042] (1) Mix melamine phosphate and ammonium dihydrogen phosphate, add perlite and pigment during the stirring process, and disperse at a high speed of 3900 r / min for 25 minutes to obtain a color paste;

[0043] (2) Make an emulsion of hydroxyacrylic resin, alkyd resin, trimethylolpropane triacrylate and etherified fluorocarbon resin, mix with pentaerythritol and the above-mentioned color paste, and disperse at a low speed of 1000r / min for 15 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com