Epoxy priming paint used for moisture resisting megawatt wind-power blades and preparation method thereof

A technology of wind power blades and epoxy primers, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems that the moisture resistance is difficult to meet the design service life of wind power blades, the cost of wind power blades is high, and the price is high, so as to achieve excellent attachment Strong, anti-cracking, fast-drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

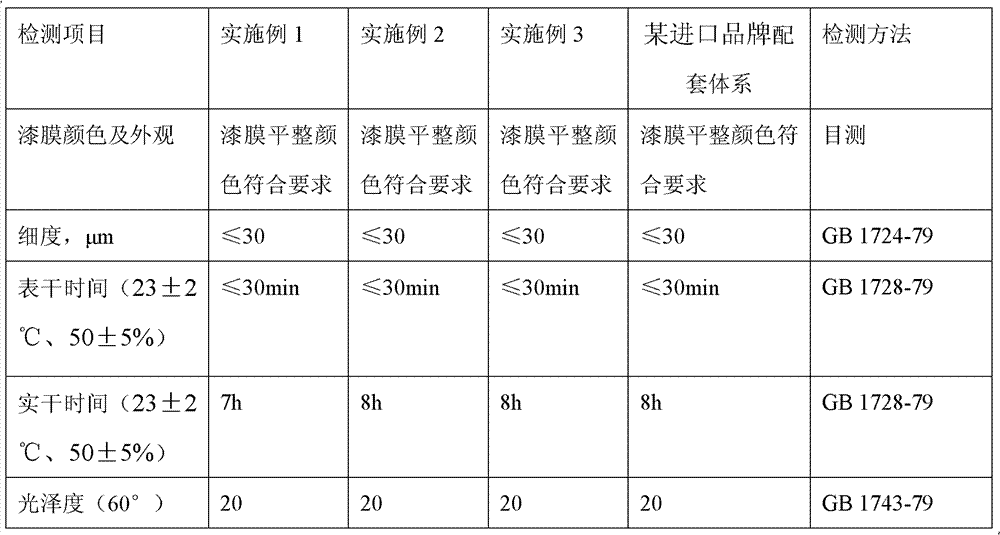

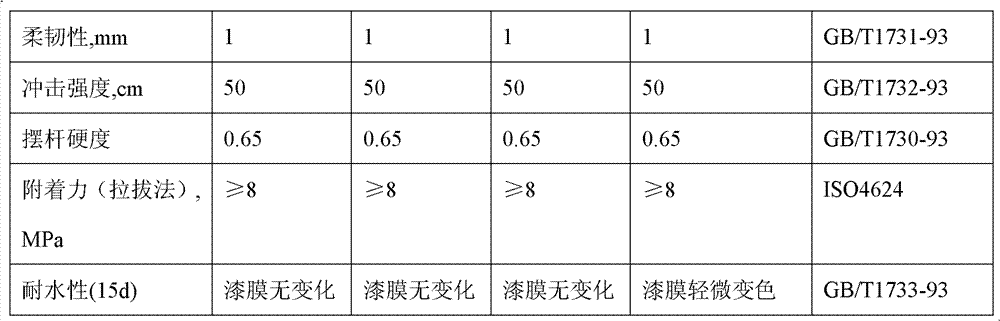

Examples

Embodiment 1

[0033] The epoxy primer component A of the wind power blade of the present embodiment includes (parts by weight, the same below): 18 parts of bisphenol A epoxy resin, 55 parts of pigments and fillers (zinc phosphate, titanium dioxide), 2 parts of anti-settling agent bentonite , 5 parts of matting agent fumed silica, 1 part of polyester modified polyphosphate dispersant, 1 part of organically modified silicone defoamer, 0.5 part of silicone leveling agent, 0.5 part of epoxy silicone Alkane coupling agent, 20 parts of mixed solvent of xylene and n-butanol (the weight ratio of xylene and n-butanol is 4:1).

[0034] Its preparation method is: (1) Add 18 parts of epoxy resin, 1 part of dispersant (AFCONA-5010), 1 part of defoamer (793) and 20 parts of mixed solvent composed of xylene and n-butanol into the dispersion vessel , use a high-speed disperser to disperse for 10-20 minutes, and control the stirring rate at 1500-2500 rpm. (2) Weigh 55 parts of pigments and fillers, 2 parts...

Embodiment 2

[0038] The epoxy primer component A of the wind power blade of the present embodiment includes: 20 parts of bisphenol A epoxy resin, 55 parts of pigments and fillers (titanium dioxide and talcum powder), 3 parts of anti-settling agent bentonite, 4 parts of matting agent gas phase two Silicon oxide, 1.2 parts of polyester modified polyphosphate dispersant, 1.5 parts of organomodified silicone defoamer, 1 part of silicone leveling agent, 1 part of epoxy siloxane coupling agent, 20 parts Mixed solvent (weight ratio of xylene and n-butanol 3:1).

[0039] Its preparation method is: (1) 20 parts of epoxy resin, 1.2 parts of dispersant (AFCONA-5010), 1.5 parts of defoamer (Bolitong AF 9903) and 20 parts of a mixed solvent composed of xylene and n-butanol are added to a dispersing vessel, dispersed with a high-speed disperser for 10-20 minutes, and the stirring rate is controlled at 1500-2500 rpm. (2) Weigh 55 parts of pigments and fillers, 3 parts of anti-sedimentation agent and 3 ...

Embodiment 3

[0043] The epoxy primer component A of the wind power blade of the present embodiment comprises: 25 parts of bisphenol A epoxy resins, 55 parts of pigments and fillers (talcum powder and kaolin), 4 parts of anti-settling agent bentonite, 3 parts of matting agent gas phase dioxide Silicon, 1.5 parts of polyester modified polyphosphate dispersant, 2 parts of organomodified silicone defoamer, 1 part of silicone leveling agent, 1 part of epoxy siloxane coupling agent, 25 parts of two A mixed solvent of toluene and n-butanol (the weight ratio of xylene to n-butanol is 5:1).

[0044] Its preparation method is: (1) Add 25 parts of epoxy resin, 1.5 parts of dispersant (AFCONA-5010), 2 parts of defoamer (793) and 20 parts of mixed solvent composed of xylene and n-butanol into the dispersion vessel , use a high-speed disperser to disperse for 10-20 minutes, and the stirring rate is controlled at 1500-2500 rpm. (2) Weigh 55 parts of pigments and fillers, 4 parts of anti-sedimentation ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com