Production method of wear-resistant anti-corrosion inner-coating oil pipe

A production method and inner coating technology, applied in the direction of anti-corrosion coatings, coatings, devices for coating liquid on the surface, etc., can solve the problems of poor high temperature heat resistance, changing the inner diameter of oil pipes, long curing time, etc., and achieve wear resistance Good anti-corrosion performance, prolonging the life of the oil pipe, and reducing the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

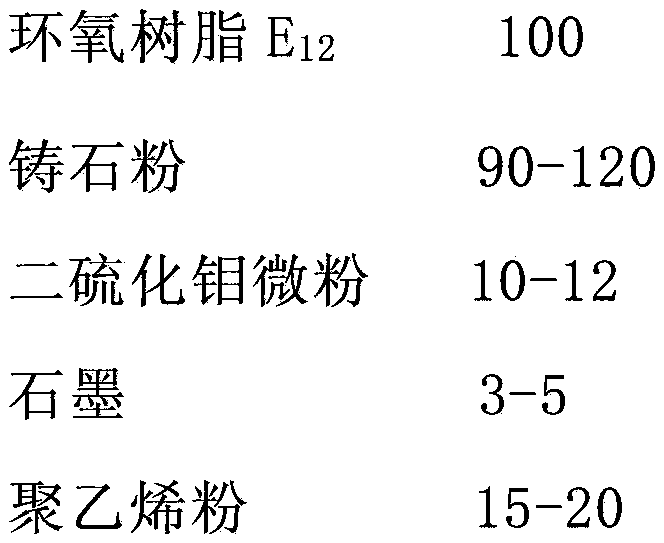

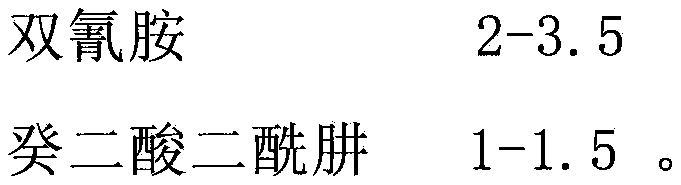

[0033] Epoxy E 12 100 grams, 90 grams of cast stone powder, 3 grams of graphite, 10 grams of molybdenum disulfide micropowder, 20 grams of polyethylene powder, 3.5 grams of dicyandiamide, 1 gram of sebacic acid dihydrazide, sprayed on the workpiece by the above-mentioned production process, processed Into a wear-resistant anti-corrosion coating workpiece. The adhesion test was carried out according to the SY / T04442-1997 standard, which met the requirements of the industry standard Class A; the tensile strength was above 150MPa; the coating had no obvious change after 168 hours of high temperature and high pressure corrosion test; the friction pair was 20CrMo, which is a common material for sucker rods, The measured friction coefficient of the coating is 0.14, which is much lower than the friction coefficient of N80 tubing, which is 0.61; 400,000 times of reciprocating wear tests show that the wear resistance is 29.3 times higher than that of N80 tubing.

Embodiment 2

[0035] 95% of an oilfield is developed by directional wells, leading to the widespread existence of wells with large well deviation and complex well trajectory, resulting in serious eccentric wear of pipes and rods, which seriously affects the normal production of the oilfield. 102 wells with severe eccentric wear were selected for on-site tests. Wear-resistant and anti-corrosion inner-coated oil pipes were run in the eccentric wear wells of these wells during pump inspection. The results showed that the average wear cycle of the oil pipes had been extended from the original 104 days to 639 days. The average service life of oil pipes has been increased by more than 4 times, and the maximum has been extended to 6.1 times, which has significantly improved the wellbore efficiency and significantly extended the repair-free period of oil wells.

[0036] The formula is as follows (weight ratio):

[0037] epoxy resin 12 100 grams, 110 grams of cast stone powder, 4 grams of graphite...

Embodiment 3

[0048] Due to the long development time in a certain operation area of an oilfield, the water content of oil wells is generally high, with an average of more than 80%, which leads to the coexistence of corrosion and wear problems, which intensifies the eccentric wear between the sucker rod and the tubing, and frequent tubing leakage, corrosion and perforation These problems have seriously affected the normal production of oil wells in this operation area. In this operation area, 24 wells with severe eccentric wear were selected for on-site tests. During the pump inspection, wear-resistant and anti-corrosion inner-coated tubing was run in the eccentric wear well sections of the 24 test wells. The results showed that the average wear cycle of the tubing had changed from the original 97 Days extended to 583 days, the average life of tubing increased by more than 3 times, and the maximum has been extended to 4.6 times, which significantly prolongs the repair-free period of oil we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com