Anticorrosive mirror back protecting coating and preparation method thereof

A protective coating and anti-corrosion technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as blurred mirror surfaces, and achieve the effects of large surface tension coefficient, excellent acid resistance, excellent water and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

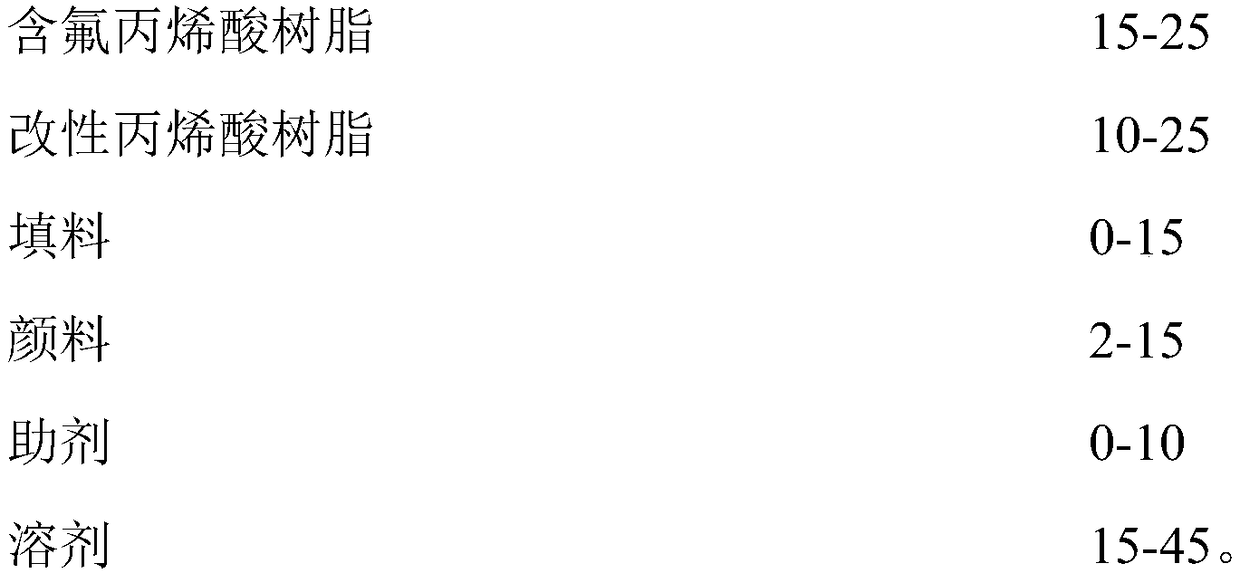

[0021] The present invention provides a kind of mirror back protection coating with anticorrosion, and by weight percentage, described coating comprises following raw material:

[0022]

[0023] The fluorine-containing acrylic resin is a polymer of perfluoroethylene and fluorine-containing acrylic monomer, wherein the fluorine-containing acrylic monomer is not less than 60% of the total weight of the monomers.

[0024] The modified acrylic resin is a polymer of trifluoropropylene oxide and fluorine-containing acrylic monomer, wherein the fluorine-containing acrylic monomer is not less than 60% of the total weight of the monomers.

[0025] The fluorine-containing acrylic monomer is one or more of trifluoroethyl acrylate and trifluoroethyl methacrylate, that is, the fluorine-containing acrylic monomer is trifluoroethyl acrylate, or trifluoroethyl methacrylate Ethyl ester, or a mixture of trifluoroethyl acrylate and trifluoroethyl methacrylate in any proportion.

[0026] The ...

Embodiment 2

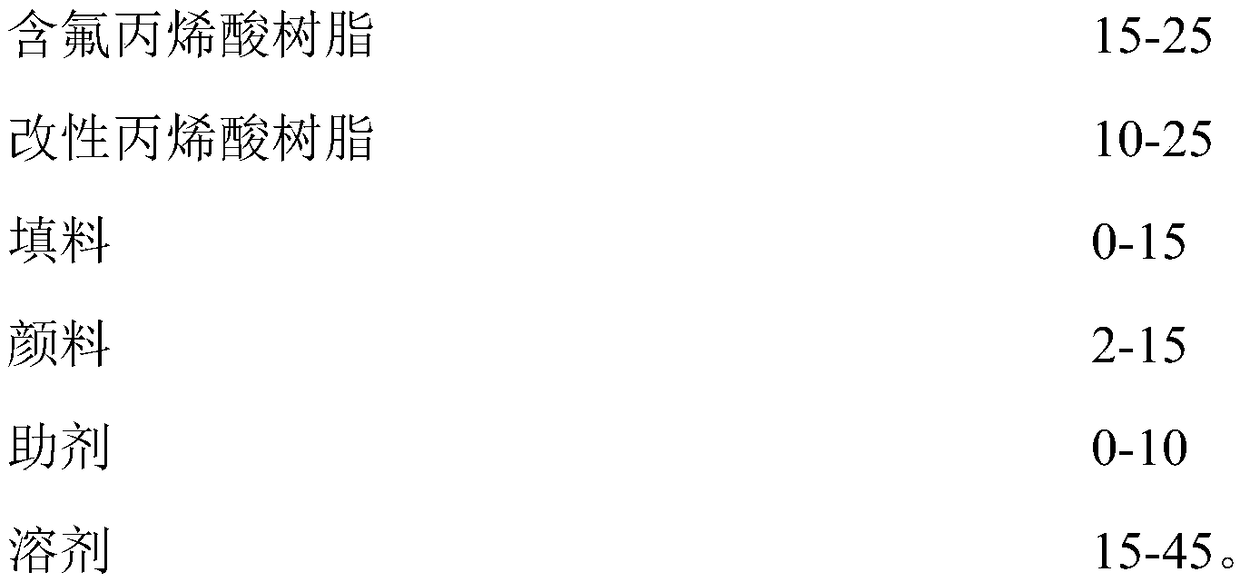

[0033] On the basis of embodiment 1, present embodiment 2 is as a preferred embodiment of the present invention, and a kind of mirror back protection paint with anticorrosion, by weight percentage, comprises following raw material:

[0034]

[0035]

[0036] Wherein, the filler is prepared from aluminum tripolyphosphate, glass flakes, mica powder and wollastonite in a weight ratio of 12:10:7:6; , N-methylpyrrolidone and ethanol are prepared by mixing in a weight ratio of 20:21:22:29; the preparation method of the mirror back protective coating is the same as in Example 1.

Embodiment 3

[0038] On the basis of embodiment 2, present embodiment 3 is as preferred embodiment of the present invention, and a kind of mirror back protection paint with corrosion resistance, by weight percentage, comprises following raw material:

[0039]

[0040] Wherein, the preparation method of the mirror back protective coating is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com