Nonlead glass composition

A lead-free glass and composition technology, applied in the direction of inorganic insulators, ceramics, electrical components, etc., can solve the problems of increasing the softening point, peeling off, and not being able to improve the acid resistance of the glass, and achieve the effect of good acid resistance and good acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

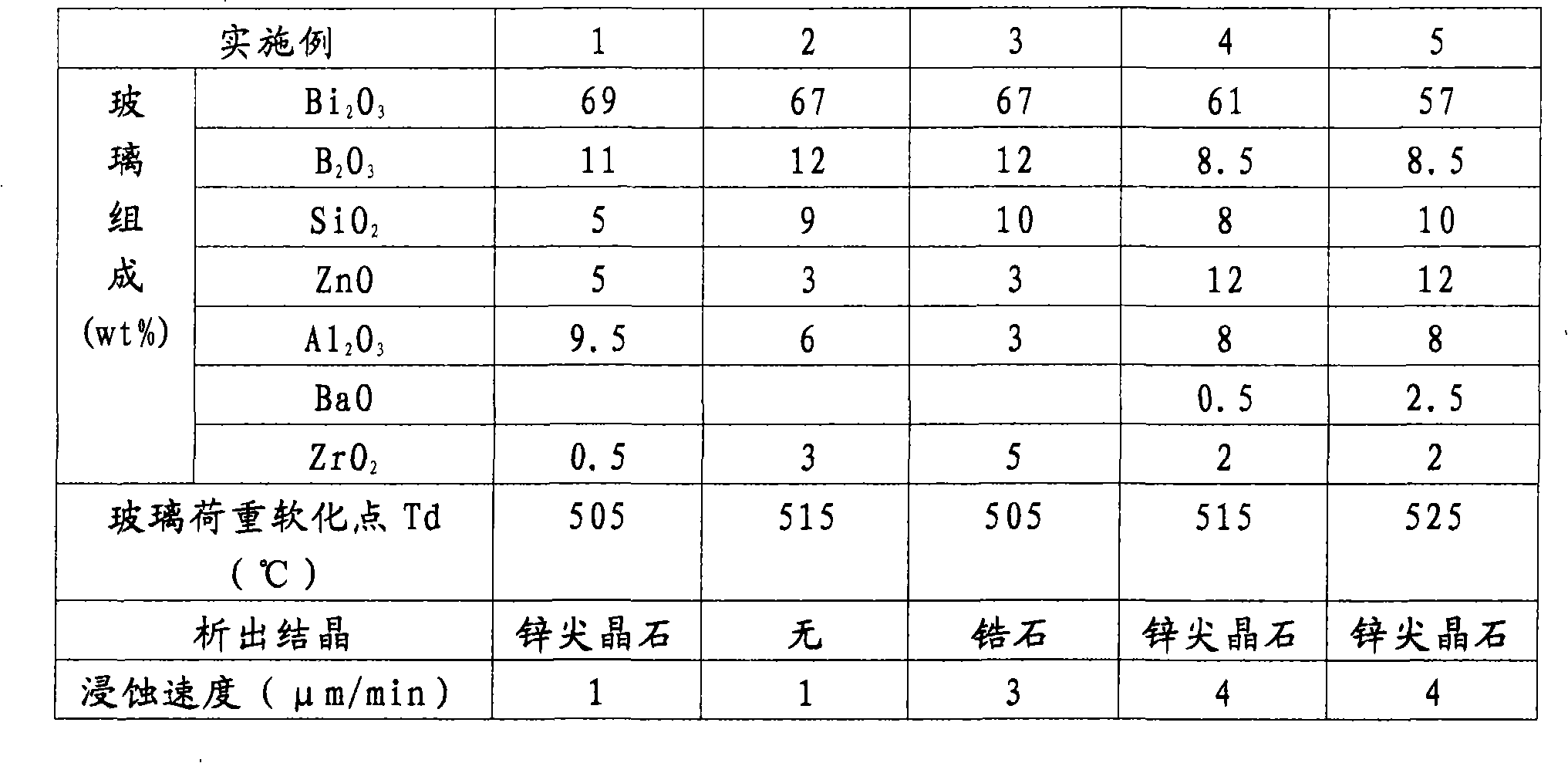

Embodiment 1~5 and comparative example 1~5

[0060] Prepare and mix the raw materials of Examples 1-5 according to the composition shown in Table 1, put them into a platinum crucible, melt them at 1200-1300° C. for 2 hours, and flow them out into a mold to make a glass block. Further, the molten glass was rapidly cooled to obtain glass flakes. The glass flakes and ion-exchanged water were put into a pot mill, wet-milled until the average particle size became 0.8-0.9 μm, and then dried by hot air drying to produce glass powder.

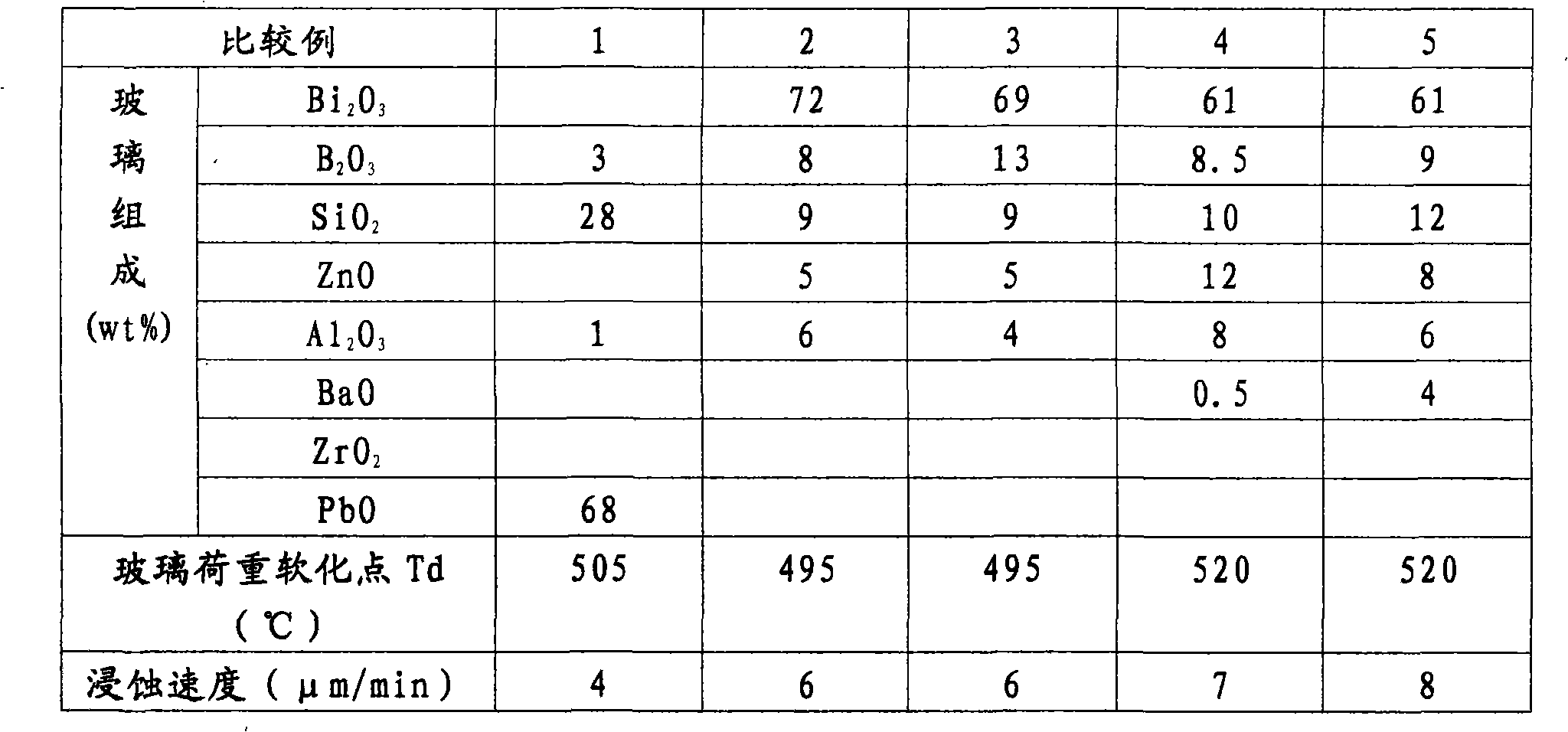

[0061] Similarly, glass powders of Comparative Examples 1 to 5 were prepared so as to have the component compositions shown in Table 2.

[0062] About each Example and a comparative example, glass load softening point Td (degreeC) and acid resistance were measured. In addition, the identification of the precipitate was performed about an Example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com