Electroseamed steel pipe for line pipe

An electric resistance welded steel pipe and electric resistance welding technology, applied in the furnace type, furnace, heat treatment furnace, etc., can solve the problems of increasing yield strength and tensile strength, and achieve the effects of excellent toughness, excellent acid resistance, and reduced yield ratio.

Inactive Publication Date: 2018-12-21

NIPPON STEEL CORP

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In paragraph 0019 of this patent document 3, it is described that "in the conventional electric resistance welded steel pipe with a large amount of Nb, under the action of the processing strain introduced during pipemaking, the precipitation of Nb carbides proceeds, so that the yield strength and resistance Tensile strength increased

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

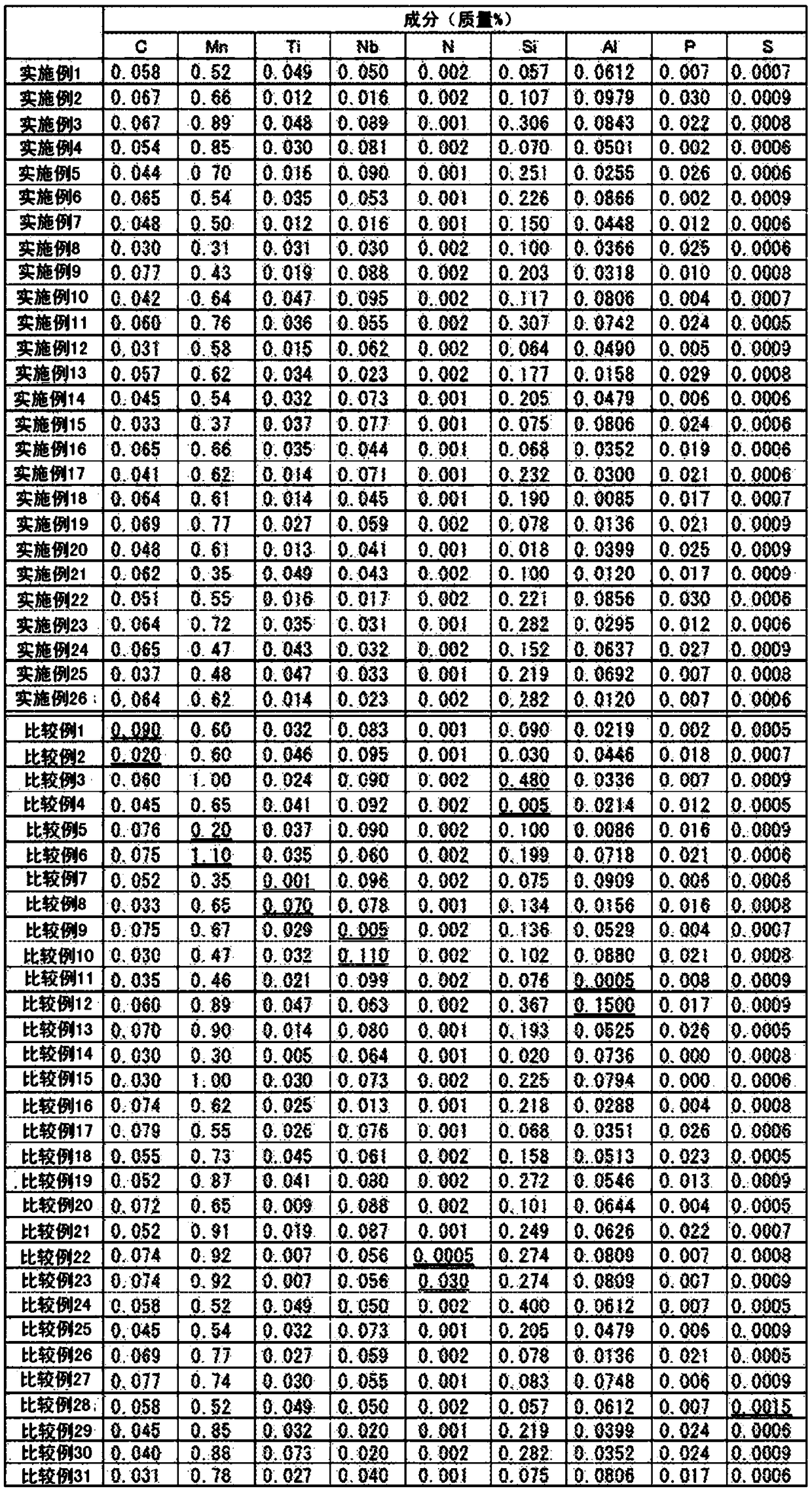

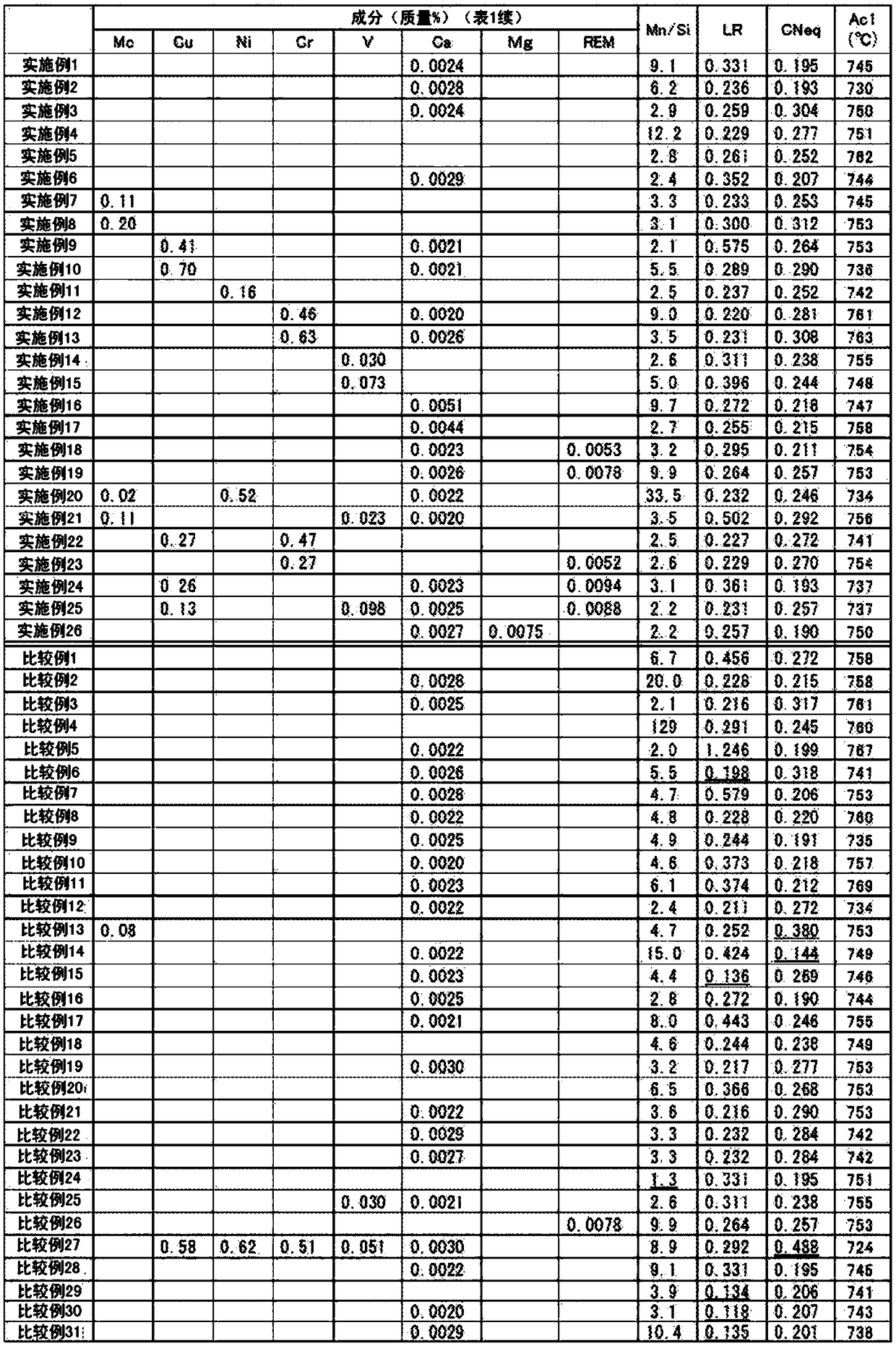

Embodiment 1~26、 comparative example 1~31

[0298]

[0299] Billets having the chemical compositions shown in Table 1 and Table 2 were prepared.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

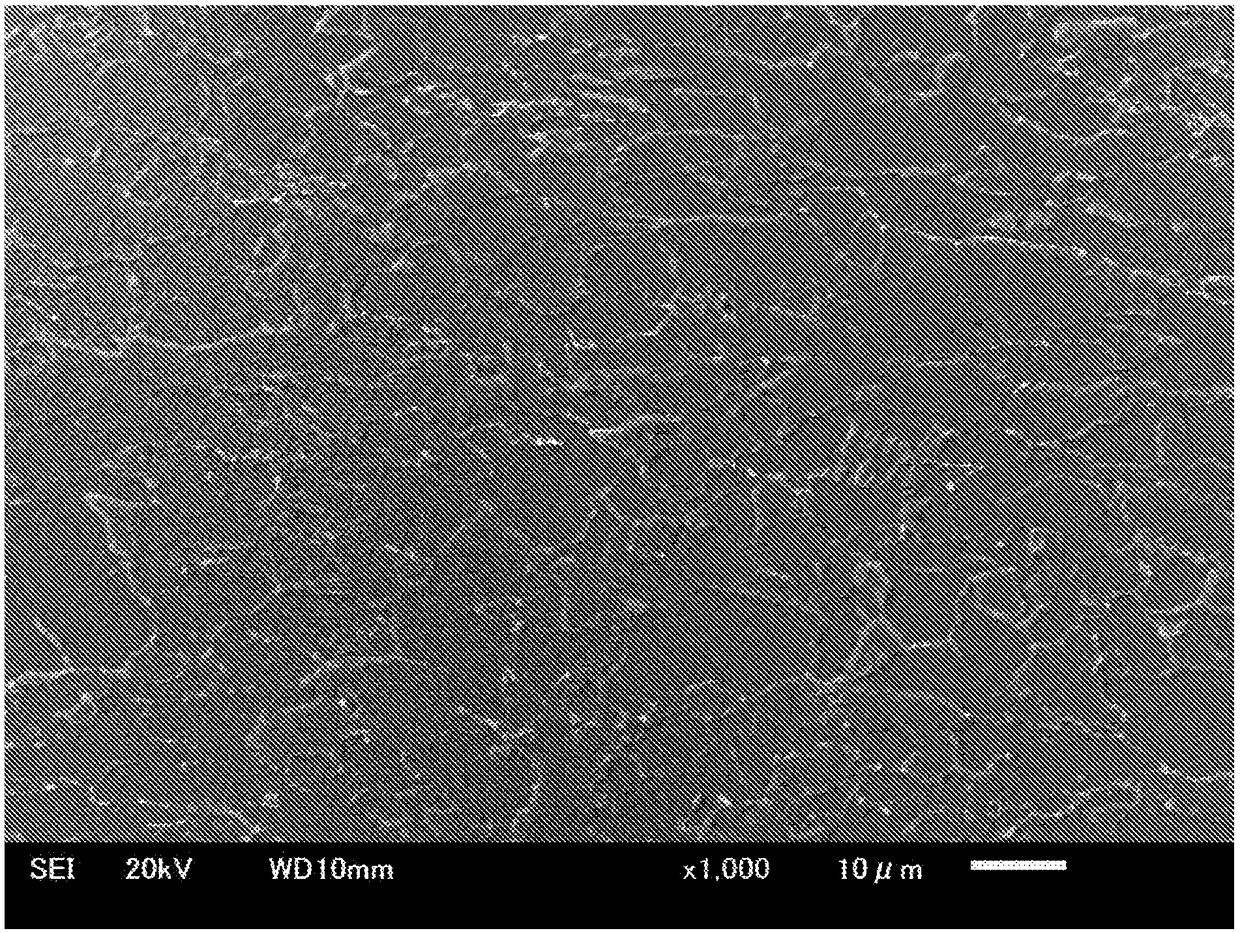

An electroseamed steel pipe for line pipe wherein: the chemical composition of the base metal section comprises, in mass%, C: 0.030% to less than 0.080%, Mn: 0.30-1.00%, Ti: 0.005-0.050%, Nb: 0.010-0.100%, N: 0.001-0.020%, Si: 0.010-0.450% and Al: 0.001-0.100%, the balance comprising Fe and impurities; CNeq represented by equation (1) is 0.190-0.320; Mn / Si ratio is at least 2.0; LR represented byequation (2) is at least 0.210; and when the metal structure of the base metal section is viewed at a 1000-fold magnification using SEM, the ferrite area ratio is 40-80% and the balance comprises tempered bainite. CNeq=C+Mn / 6+Cr / 5+(Ni+Cu) / 15+Nb+Mo+V... Equation (1) LR=(2.1*C+Nb) / Mn... Equation (2)

Description

technical field [0001] The present invention relates to an electric resistance welded steel pipe (electroseamed steel pipe: electric seam steel pipe) for a line pipe. Background technique [0002] In recent years, the importance of mainline pipes, which are mainly one of the transportation means of crude oil or natural gas, has increased. [0003] Various studies are being conducted on electric resistance welded steel pipes used as line pipes (ie, electric resistance welded steel pipes for main line pipes). [0004] For example, Patent Document 1 proposes a hot-rolled steel sheet for a sour resistance high-strength electric resistance welded steel pipe in which bainitic ferrite in the steel structure is 95 vol% or more. [0005] Patent Document 2 discloses a technique of inducing a Bauschinger effect by repeatedly deforming a steel strip as a raw material by, for example, bending-return processing before pipe forming, thereby enabling The yield ratio in the pipe axis direc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/00C21D9/08C22C38/14C22C38/50C21D8/02

CPCC21D8/0205C21D8/0226C21D8/105C21D9/08C21D2211/002C21D2211/005C22C38/001C22C38/002C22C38/005C22C38/02C22C38/04C22C38/06C22C38/08C22C38/12C22C38/14C22C38/16C22C38/26C22C38/28C21D8/02C22C38/00C22C38/50

Inventor 长井健介尾崎雅和长谷川昇

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com