Easily dyeable meta-form wholly aromatic polyamide fiber

A polyamide fiber and fully aromatic technology, which is applied in the field of dyeable meta-type fully aromatic polyamide fiber, can solve the problems of difficulty in obtaining acid resistance and insufficient fiber crystallization, and achieve excellent environmental stability and dyeability Good, excellent acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] [Spinning solution preparation process]

[0111] 20.0 parts by mass of polym-phenylene isophthalamide powder with an intrinsic viscosity (I.V.) of 1.9 produced by the interfacial polymerization method based on the method described in Japanese Patent Publication No. 47-10863, after cooling to - It was suspended in 80.0 parts by mass of N-methyl-2-pyrrolidone (NMP) at 10° C. to obtain a slurry. Next, the temperature of the suspension was raised to 60° C. and dissolved to obtain a transparent polymer solution A.

[0112] [Spinning and coagulation process]

[0113] The above-mentioned polymer solution A was used as a spinning stock solution, and it was sprayed from a spinning nozzle with a hole diameter of 0.07 mm and a number of holes of 500 into a coagulation bath with a bath temperature of 30° C. for spinning. The composition of the coagulation liquid was water / NMP=45 / 55 (parts by mass), and it was sprayed into the coagulation bath at a wire speed of 7 m / min, and spun....

Embodiment 2

[0127] [Spinning solution preparation process]

[0128] 854.8 parts of N-methyl-2-pyrrolidone (hereinafter, abbreviated as NMP) was charged into a reaction container equipped with a stirring device and a raw material inlet, and 83.4 parts of m-phenylenediamine (hereinafter, abbreviated as MPDA) were dissolved in the NMP. Furthermore, 156.9 parts of isophthalic acid chlorides (it abbreviates as IPC hereafter) were slowly added to this solution, stirring, and it reacted. After the stirring was continued for 40 minutes from the start of the reaction, 57.1 parts of calcium hydroxide powder was added, and the reaction was completed after further stirring for 40 minutes. When the polymerization solution was taken out from the reaction vessel, the polymerization solution was transparent and the polymer concentration was 16%.

[0129] [Spinning and coagulation process, plastic drawing bath stretching process, cleaning process, steam relaxation heat treatment process, dry heat treatme...

Embodiment 3

[0138] [production of fibril]

[0139] A polym-phenylene isophthalamide fiber was obtained in the same manner as in Example 2, except that the draw ratio in the plastic drawing bath was set to 4.5 times, and the surface temperature in the dry heat treatment step was set to 280°C.

[0140] [Physical properties of fibrils]

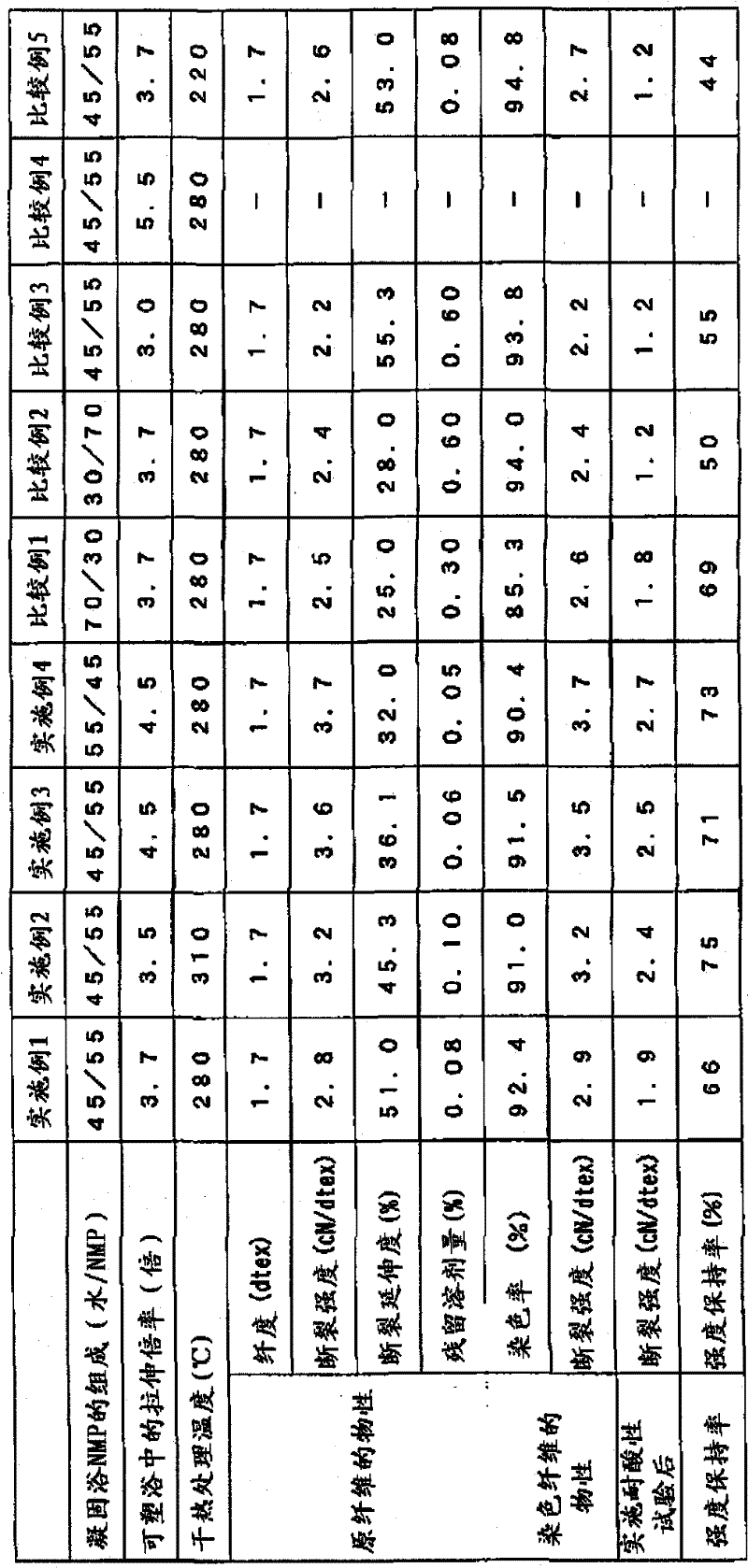

[0141] The physical properties of the obtained fiber were a fineness of 1.7 dtex, a breaking strength of 3.6 cN / dtex, a breaking elongation of 36.1%, and a residual solvent amount of 0.06% by mass. Table 1 shows the physical properties of the obtained fibers.

[0142] [dyeing process]

[0143] The same dyeing process as in Example 1 was performed on the obtained fiber.

[0144] [Physical properties of dyed fiber, etc.]

[0145] The dyeing rate was 91.5%, showing good dyeability. In addition, the breaking strength of the dyed fiber was 3.5 cN / dtex, and the breaking strength of the dyed fiber after the acid resistance test was 2.5 cN / dtex, and the strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com