Preparation technologies of modified copolyester chip and fiber

A preparation process and copolyester technology, which is applied in the direction of single-component copolyester rayon, etc., can solve the problems of difficult and accurate control of copolyester components, disordered ethylene glycol composition ratio, and unstable product performance. Achieve the effects of bright colors, good fabric resilience and good dyeability of disperse dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

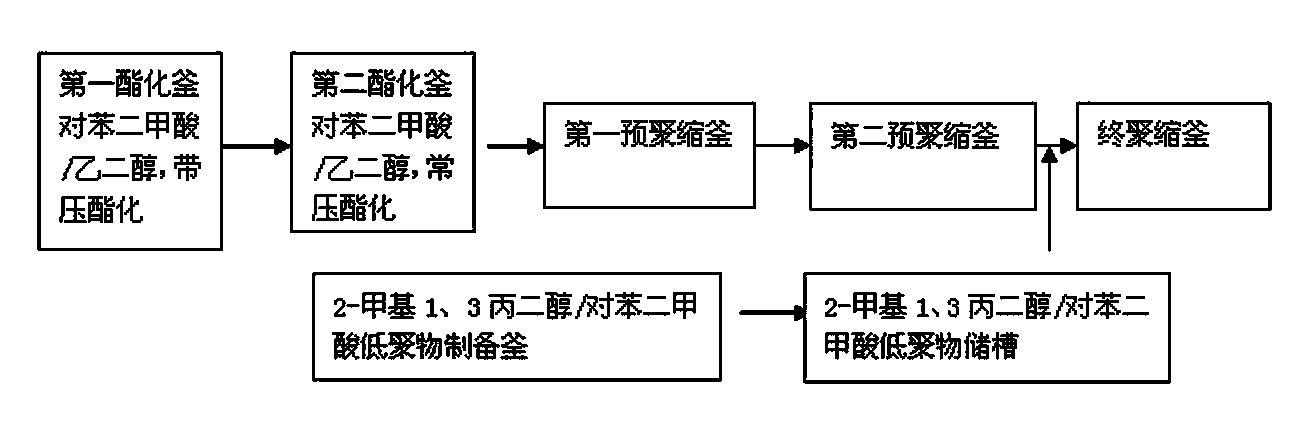

[0028] A kind of preparation technology of normal temperature and pressure disperse dyeable polyester chip and fiber, its process flow chart is as follows figure 1 As shown, proceed as follows:

[0029] (1) Using 20 L batch polymerization equipment, add 1 mol of PTA, 1.4 mol of MPDO and ethylene glycol antimony equivalent to 0.013 wt % of PTA weight at the same time. Under the condition of 250° C., stirring for about 2.0 hours, the esterification reaction was carried out.

[0030] (2) After the effluent reaches the theoretical amount, decompress and then vacuumize for about 40 minutes. After the system reaches low vacuum, release the vacuum to normal pressure and release the product, which is 2-methyl 1,3-propanediol / terephthalic acid low Polymer BHMPOT. The oligomer BHMPOT has a degree of polymerization of about 3~4 and basically no free 2-methyl-1,3-propanediol.

[0031] (3) Using 300 L batch polymerization equipment, add 1 mol of PTA, 1.30 mol of EG, and ethylene glycol ...

Embodiment 2

[0037] A kind of preparation technology of normal temperature and pressure disperse dyeable polyester chip and fiber, its process flow chart is as follows figure 1 As shown, proceed as follows:

[0038] (1) Using 3M3 batch polymerization equipment, add 1 mol of PTA, 1.4 mol of MPDO and ethylene glycol antimony equivalent to 0.013 wt% of PTA weight at the same time, at a pressure of 0.20MPA~0.35MPA and a temperature of 230~250℃ Under the condition, stir about 4.0 hours, carry out esterification reaction.

[0039] (2) After the effluent reaches the theoretical amount, depressurize and evacuate for about 1.4 hours. After the system reaches low vacuum, release the vacuum to normal pressure, and release the product to the BHMPOT insulation (temperature about 265°C) storage tank, which is 2-methyl 1. 3 propylene glycol / terephthalic acid oligomer BHMPOT. The oligomer BHMPOT has a degree of polymerization of about 3~4 and basically no free 2-methyl-1,3-propanediol.

[0040] (3) Add...

Embodiment 3

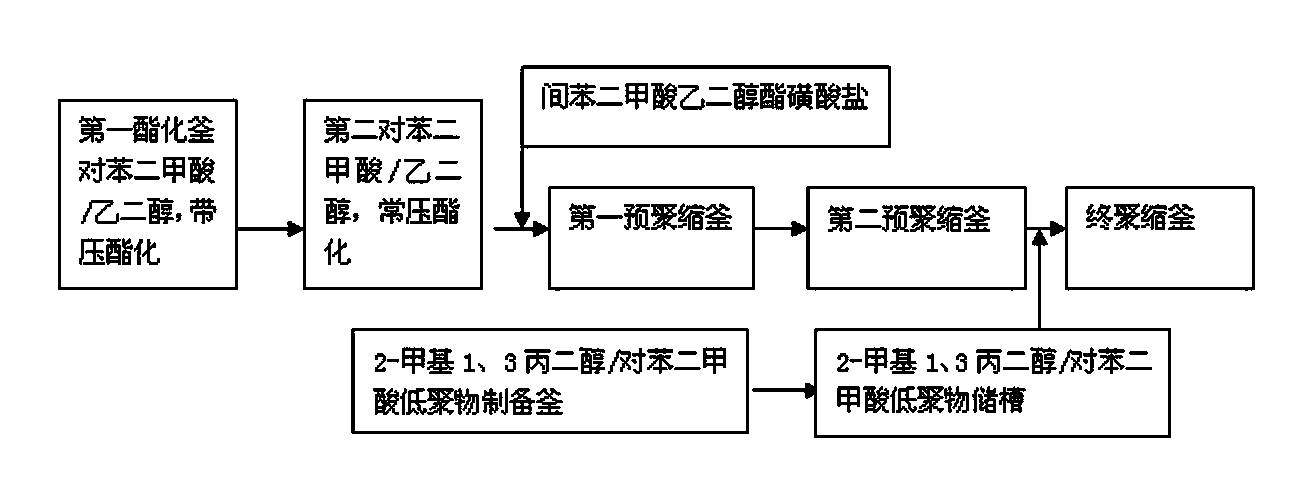

[0043] A kind of normal temperature and normal pressure cationic dyeable polyester chip and fiber preparation process, its process flow chart is as follows figure 2 As shown, proceed as follows:

[0044] (1) Using 20 L batch polymerization equipment, add 1 mol of PTA, 1.4 mol of MPDO and ethylene glycol antimony equivalent to 0.013 wt % of PTA weight at the same time. Under the condition of 250°C, stir for about 2.0 hours to carry out the esterification reaction.

[0045] (2) After the effluent reaches the theoretical amount, decompress and then vacuumize for about 40 minutes. After the system reaches a low vacuum, release the vacuum to normal pressure to release the product, which is 2-methyl 1,3-propanediol / terephthalic acid low Polymer BHMPOT. The oligomer BHMPOT has a degree of polymerization of about 3~4, and basically no free 2-methyl-1,3-propanediol.

[0046] (3) Using 300 L batch polymerization equipment, add 1 mol of PTA, 1.30 mol of EG and ethylene glycol antimon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com