Sirofil pure cotton elastic yarn and manufacturing and application thereof

A technology of sirofil spinning and elastic yarn, which is applied in the direction of textiles and papermaking, yarn, yarn/thread/filament mercerization, etc. It can solve the problem of reducing hand feeling performance and wearing comfort performance, not giving yarn elasticity, single yarn High twist, etc., to achieve the effect of improved dyeability, less color difference, and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Yarn specification

[0034] Core spun strong twist elastic yarn: 500 twists / m, 20 lbs;

[0035] Raw materials: coated fiber mesh, cotton roving, fineness 14 lbs, twist 100 twists / m;

[0036] Core layer, ring spun cotton yarn, fineness 40 lbs, twist 120 twists / m;

[0037] (2) Production process

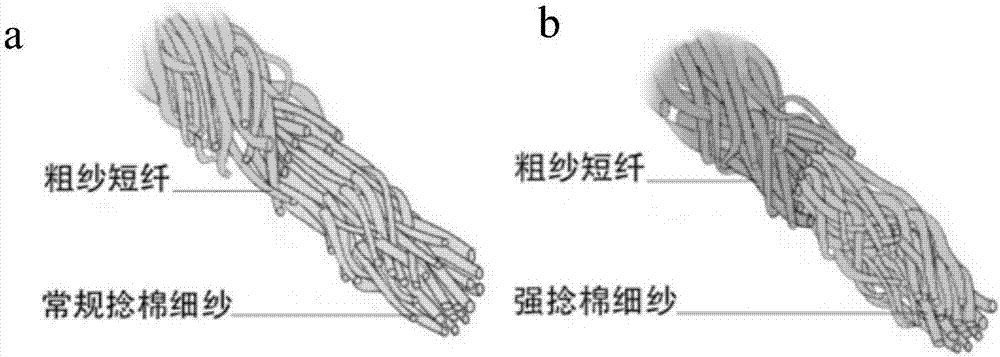

[0038] see figure 1 , the embodiment of the present invention includes: a core-spun strong-twisted elastic yarn, the covering layer is formed by the roving, and the core layer is formed by the spun yarn to form a covering structure core-spun yarn.

[0039] Both the roving and the spun yarn are pure cotton fibers, and the spun yarn is spun from the roving through a ring spinning process.

[0040] Specific steps are as follows:

[0041] (1) Preparation of spun yarn: Twisting and spinning the roving on the ring spinning frame to make spun yarn with a certain twist. The twist of the spun yarn spun in this example is 120 twists / meter;

[0042](2) Preparation of core-spun ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com