Composite modified aqueous polyurethane, preparation method and applications thereof

A water-based polyurethane and composite modification technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy agglomeration, low reactivity, and influence on the performance of polymer composite materials, and achieves good adhesion and preparation method. Simple, acid and salt water resistant results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of composite modified waterborne polyurethane, comprising the following steps:

[0030] 1) Preparation of prepolymer: Add macromolecular polyol and polyisocyanate to catalyst prepolymerization, add small molecule alcohol chain extender and small molecule carboxylic acid chain extender, add salt forming agent after dilution, and obtain waterborne polyurethane prepolymer ;

[0031] In this step, the water-based polyurethane has a more branched chain structure through the small molecule alcohol chain extender and the small molecule carboxylic acid chain extender, and the crosslinking degree of the water-based polyurethane is improved, thereby improving the hardness, flexibility, and compactness of the water-based polyurethane. Improvements in physical properties provide the basis;

[0032] In this step, macromolecule polyol is polyester polyol or polyether polyol, and its relative molecular weight is 1000 or 2000, and wh...

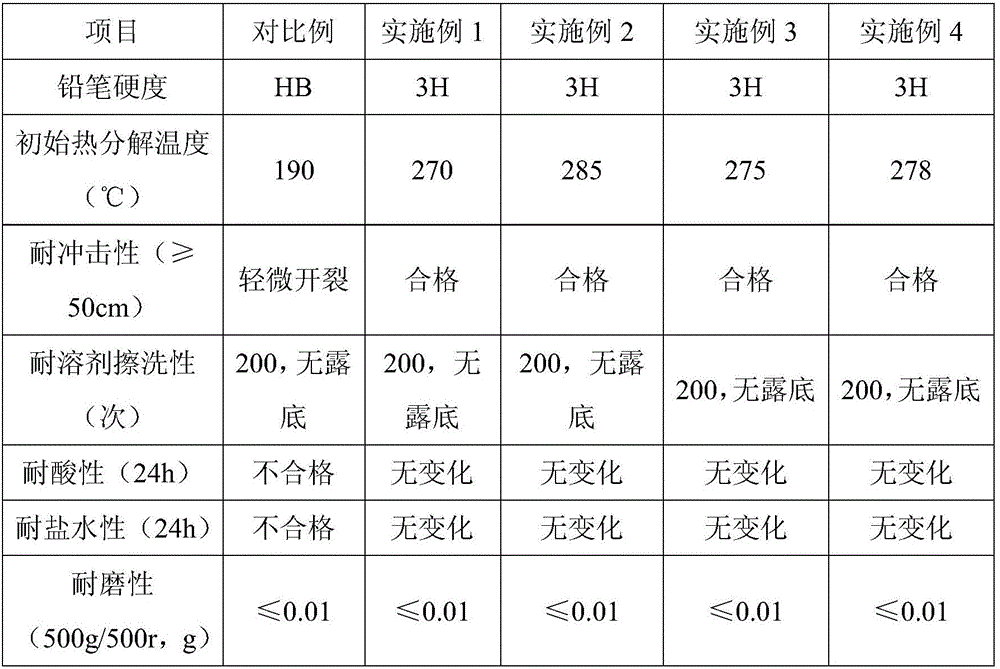

Embodiment 1

[0051] 1) Preparation of prepolymer: Add 40g of polyethylene adipate with a molecular weight of 1000 into the reaction flask, distill under reduced pressure at 100°C for 30 minutes, cool down to 70°C, add 20g of toluene diisocyanate and 0.2g of dilauric acid Dibutyltin, reacted for 2 hours;

[0052] Cool down to 50°C, add 2g 1,4-butanediol, 2g 2,2-dimethylolpropionic acid, 2g trimethylolpropane, and react for 4 hours until the NCO content reaches the theoretical value;

[0053] After cooling down to 40°C and reducing the viscosity with 10g of acetone, add 2g of triethylamine and react for 30 minutes to obtain a prepolymer of water-based polyurethane;

[0054] 2) Modification of silica sol: Dilute 20 g of acidic silica sol with 10 g of isopropanol, then mix with 10 g of methyltrimethoxysilane, stir and react at room temperature for 4 hours, to obtain silica sol modified by silane coupling agent;

[0055] 3) Emulsification: Add the water-based polyurethane prepolymer obtained i...

Embodiment 2

[0059] 1) Preparation of prepolymer: Add 60g of polytetrahydrofuran diol with a molecular weight of 2000 into the reaction flask, distill under reduced pressure at 100°C for 30 minutes, cool down to 70°C, add 40g of hexamethylene diisocyanate, 0.5g of stannous octoate, React for 2 hours;

[0060] Cool down to 55°C, add 5g of diethylene glycol, 8g of 2,2-dimethylolbutyric acid and 3g of trimethylolpropane, and react for 4 hours until the NCO content reaches the theoretical value;

[0061] After cooling down to 45°C and reducing the viscosity with 20g butanone, add 5g of ammonia water and react for 15 minutes to obtain a prepolymer of water-based polyurethane;

[0062] 2) Modified silica sol: Dilute 80g of acidic silica sol with 20g of isopropanol, then mix it with 40g of KH560, stir and react at room temperature for 4h, to obtain silica sol modified by silane coupling agent;

[0063] 3) Emulsification: Add the water-based polyurethane prepolymer obtained in step 1) to the sila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com