Rare-earth-modified aluminium alloy anode plate and preparation method thereof

A rare earth modification and aluminum alloy technology is applied in the field of rare earth modified aluminum alloy anode sheets and their preparation, which can solve the problems of reducing the hydrogen evolution corrosion rate of aluminum alloy anodes, hindering the dissolution of base metal aluminum anodes, and uneven anode corrosion, etc. The effect of inhibiting hydrogen evolution corrosion reaction, reducing the number of local pitting corrosion, and improving electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

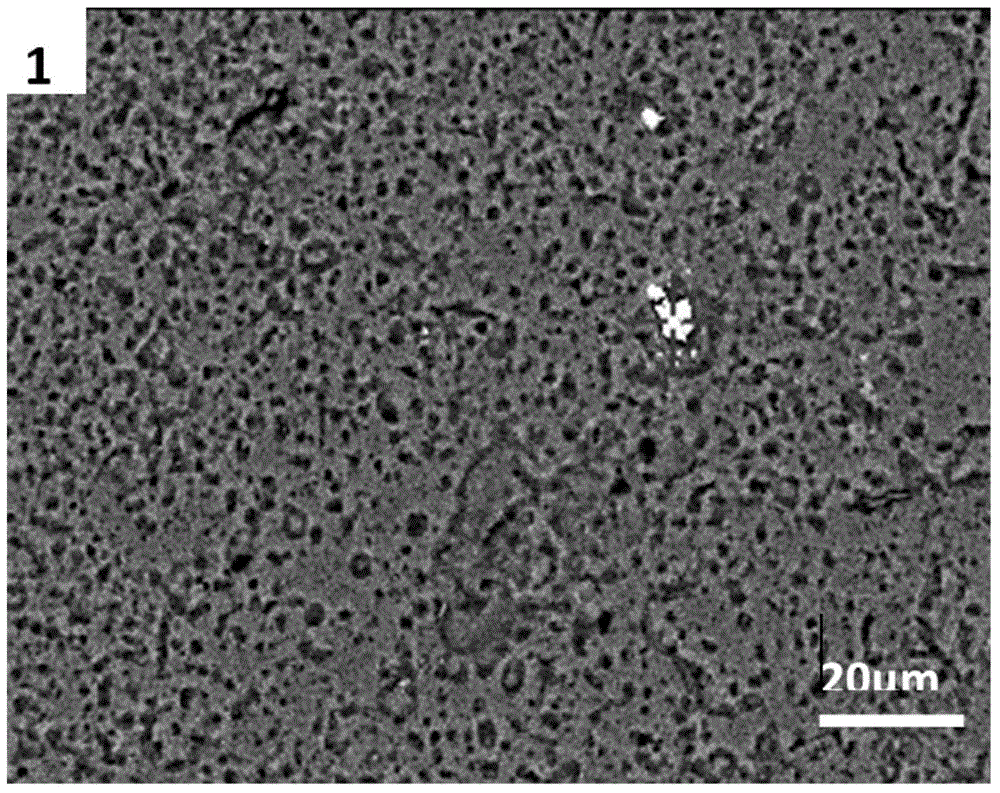

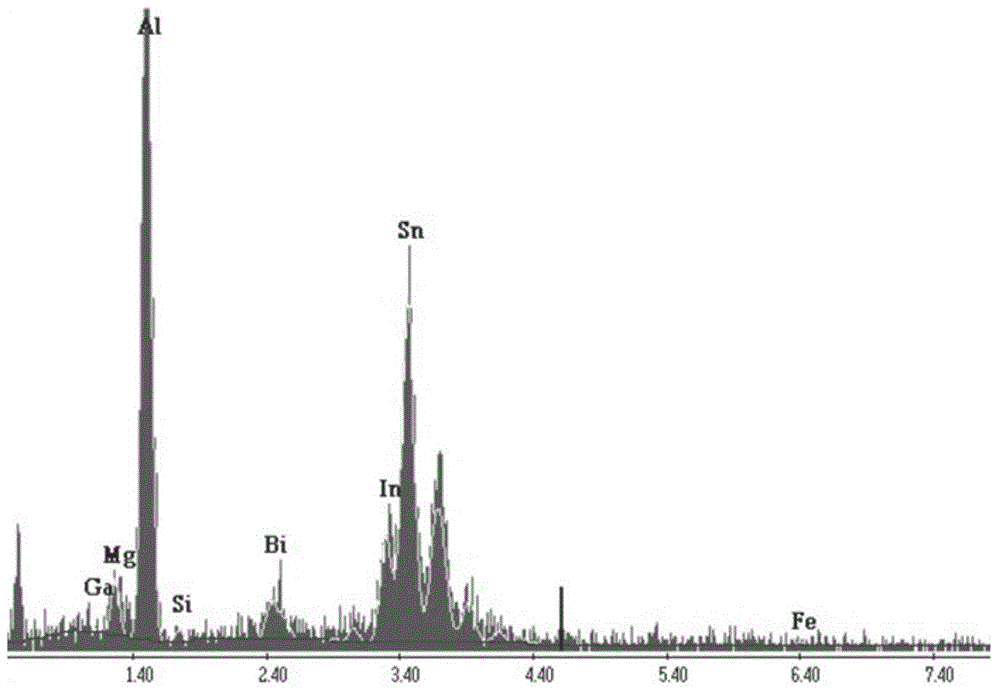

Image

Examples

Embodiment 1

[0034] The preparation method of the rare earth modified aluminum alloy anode sheet of the present invention comprises the following steps:

[0035]1) Weigh a certain amount of aluminum blocks, magnesium blocks, bismuth grains, tin grains, gallium grains, indium grains, lanthanum grains and cerium grains. The mass ratio of lanthanum grains, lanthanum grains, and cerium grains is 98.09:1:0.8:0.05:0.01:0.02:0.02:0.01. The aluminum block is preheated and heated to 750°C for melting, and then the magnesium block, bismuth grains, and tin grains are melted. , gallium grains, indium grains, lanthanum grains, and cerium grains are added to the molten aluminum to form an alloy melt. After the formed alloy melt is left to stand, it is cooled to 700°C with the furnace, and then the liquid surface of the alloy melt is removed. scum, and then casting the alloy melt into a water-cooled steel mold to form a green body;

[0036] 2) The green body obtained in step 1) is sequentially subjected...

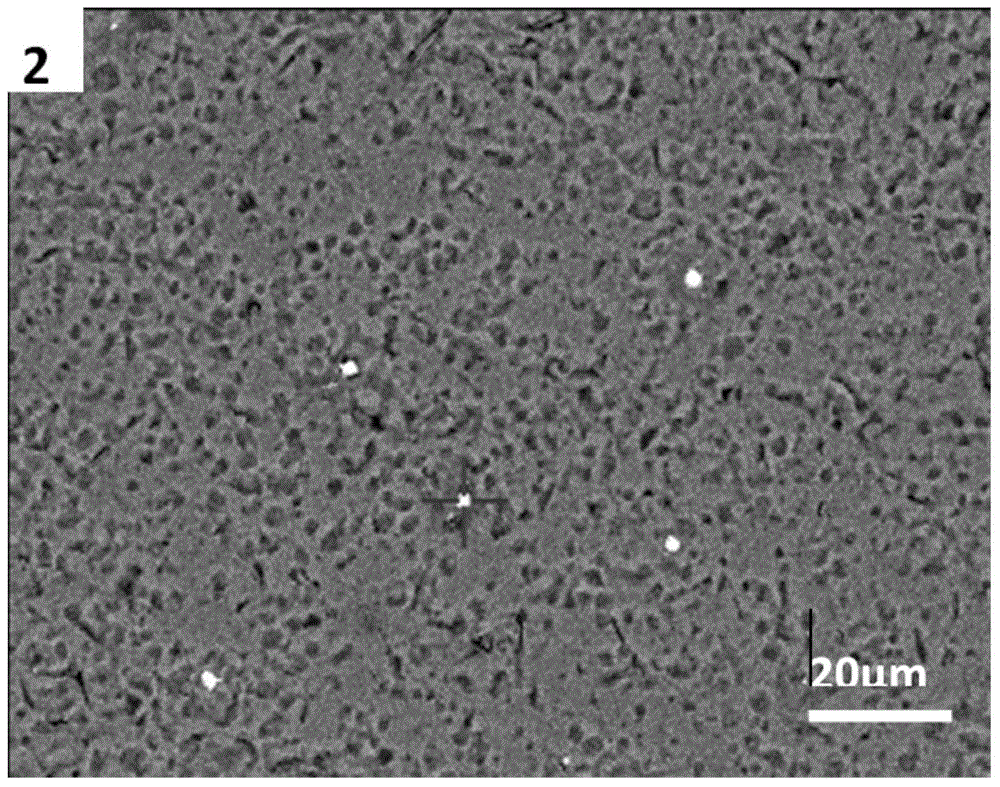

Embodiment 2

[0042] The preparation method of the rare earth modified aluminum alloy anode sheet of the present invention comprises the following steps:

[0043] 1) Weigh a certain amount of aluminum blocks, magnesium blocks, bismuth grains, tin grains, gallium grains, indium grains, lanthanum grains and cerium grains. The mass ratio of lanthanum particles to cerium particles is 98.06:1:0.8:0.08:0.01:0.02:0.02:0.01, the aluminum block is preheated and heated to 800°C for melting, and then the magnesium block, bismuth particles, tin particles, Gallium grains, indium grains, lanthanum grains, and cerium grains are added to the molten aluminum to form an alloy melt. After the formed alloy melt is left to stand, it is cooled to 700°C with the furnace, and then the floating surface of the alloy melt is removed. slag, and then cast the alloy melt into a water-cooled steel mold to form a green body;

[0044] 2) The green body obtained in step 1) is sequentially subjected to solution heat treatme...

Embodiment 3

[0050] The preparation method of the rare earth modified aluminum alloy anode sheet of the present invention comprises the following steps:

[0051] 1) Weigh a certain amount of aluminum blocks, magnesium blocks, bismuth grains, tin grains, gallium grains, indium grains, lanthanum grains and cerium grains. , The mass ratio of lanthanum particles and cerium particles is 97.87:1.5:0.5:0.05:0.01:0.02:0.03:0.02, the aluminum block is preheated and heated to 760°C for melting, and then the magnesium block, bismuth particles, tin particles, Gallium grains, indium grains, lanthanum grains, and cerium grains are added to the molten aluminum to form an alloy melt. After the formed alloy melt is left to stand, it is cooled to 700°C with the furnace, and then the floating surface of the alloy melt is removed. slag, and then cast the alloy melt into a water-cooled steel mold to form a green body;

[0052] 2) The green body obtained in step 1) is sequentially subjected to solution heat tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com