Zirconium dioxide-coated manganese lithium ion sieve as well as preparation method and application thereof

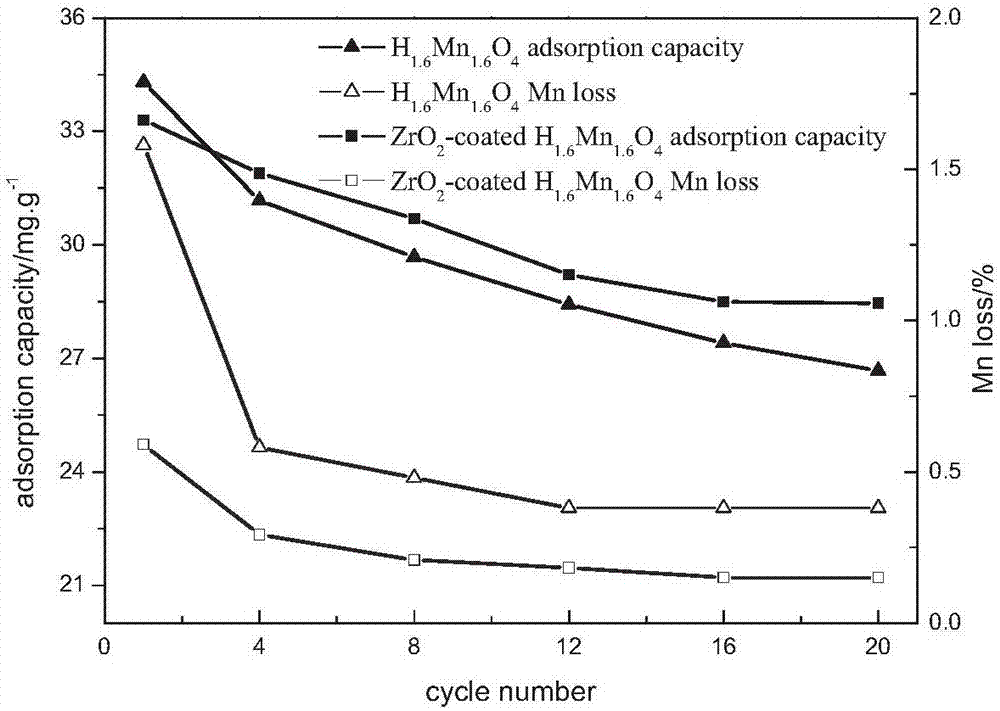

A technology of zirconium dioxide and lithium ions, applied in chemical instruments and methods, inorganic chemistry, manganese compounds, etc., can solve problems such as poor cycle performance, large manganese dissolution loss, poor acid corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

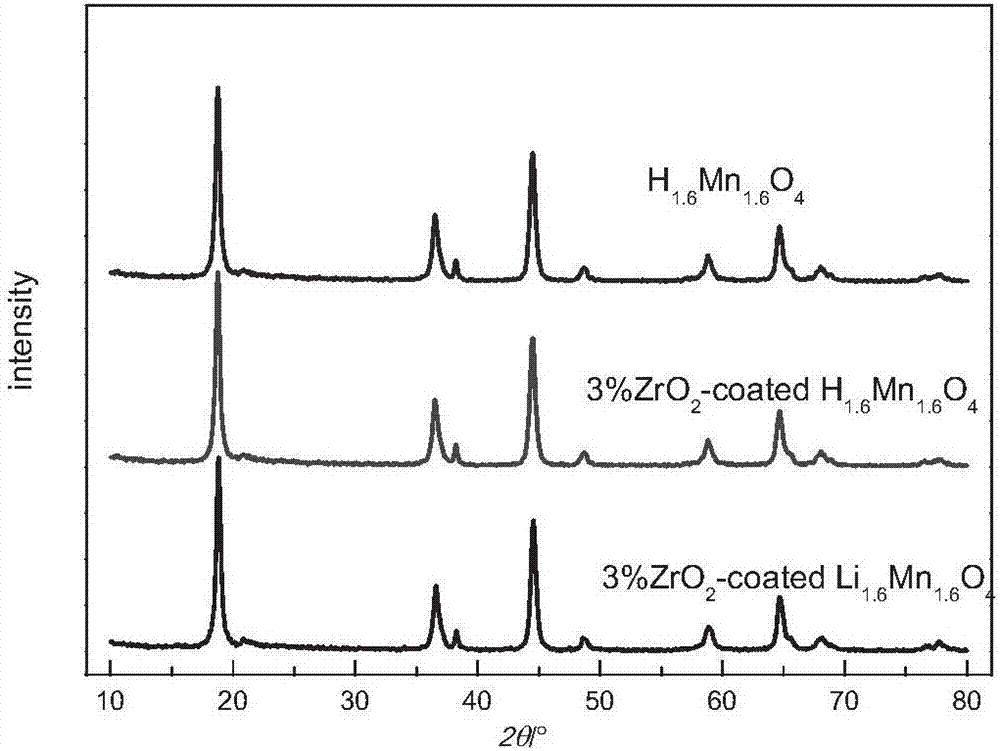

[0067] (1) Preparation of lithium ion sieve precursor Li 1.6 mn 1.6 o 4

[0068] electrolytic MnO 2 Calcined at 750°C for 500min to generate Mn 2 o 3 , Weigh 22.6gLiOH.H 2 O was dissolved in 500 mL of deionized water and slowly added 20 g of Mn 2 o 3 Powder, control the Li / Mn molar ratio to 2.0:1, first 300r.min -1 Stir for 30min at a constant speed, then 1700r.min -1 Stir at 180min at a constant speed, and finally 800r.min -1 Stir at the speed of 60min, and then put the mixed solution into the autoclave for hydrothermal reaction at 250°C for 17h to obtain LiMnO 2 , then the LiMnO 2 Calcined at 450°C for 6h to obtain 25g of precursor Li 1.6 mn 1.6 o 4 .

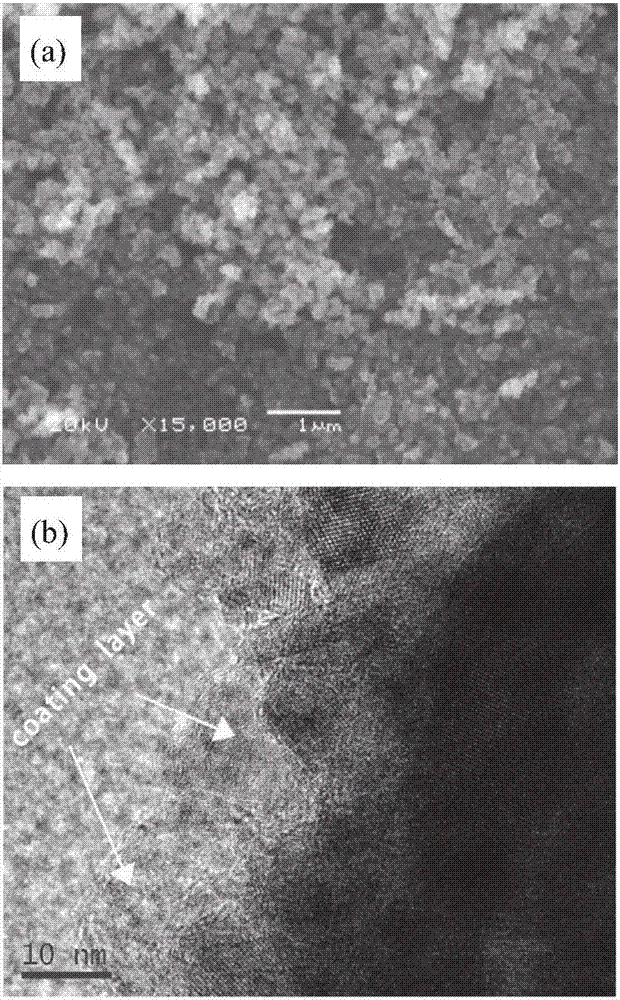

[0069](2) Preparation of coated ZrO 2 Li-ion sieve precursor

[0070] Weigh 2.1 g of zirconium nitrate pentahydrate and dissolve it in 500 mL of ethanol solution (aqueous solution), the volume ratio of ethanol to water is 5:1, add 20 g of precursor Li 1.6 mn 1.6 o 4 , ultrasonically dispersed for 20 hours,...

Embodiment 2

[0078] (1) Preparation of lithium ion sieve precursor Li 1.6 mn 1.6 o 4

[0079] electrolytic MnO 2 Calcined at 650°C for 500min to generate Mn 2 o 3 , weighed 13.9g LiOH·H 2 O was dissolved in 500 mL of deionized water and slowly added 20 g of Mn 2 o 3 Powder, control the Li / Mn molar ratio to 1.2:1, first 200r·min -1 Stir at 1500r·min for 30min -1 Stir at 240min at a constant speed, and finally 600r·min -1 Stir at a high speed for 60 minutes, then add the mixed solution into the autoclave and react for 20 hours at 200 ° C to obtain LiMnO 2 , then the LiMnO 2 Calcined at 350 °C for 10 h to obtain 25 g of precursor Li 1.6 mn 1.6 o 4 .

[0080] (2) Preparation of coated ZrO 2 Li-ion sieve precursor

[0081] Weigh 1.96 g of zirconium ethoxide and dissolve it in 300 mL of ethanol solution (aqueous solution), the volume ratio of ethanol to water is 5:1, add 20 g of precursor Li 1.6 mn 1.6 o 4 , ultrasonically dispersed for 10 h, placed in a constant temperature ...

Embodiment 3

[0087] (1) Preparation of lithium ion sieve precursor Li 1.6 mn 1.6 o 4

[0088] electrolytic MnO 2 Calcined at 800°C for 500min to generate Mn 2 o 3 , Weigh 17.0gLiOH·H 2 O was dissolved in 500 mL of deionized water and slowly added 20 g of Mn 2 o 3 Powder, control the Li / Mn molar ratio to 1.5:1, first 300r min -1 Stir at room temperature for 30min, then 2000r·min -1 Stir at 240min at a constant speed, and finally 700r·min -1 Stir at a high speed for 60 minutes, then add the mixed solution into the autoclave and react for 24 hours at 170 ° C to obtain LiMnO 2 , then the LiMnO 2 Calcined at 500 °C for 6 h to obtain 25 g of precursor Li 1.6 mn 1.6 o 4 .

[0089] (2) Preparation of coated ZrO 2 Li-ion sieve precursor

[0090] Pipette 0.8mL of 70% zirconium n-propoxide solution and dissolve in 400mL ethanol solution (aqueous solution), the volume ratio of ethanol to water is 5:1, add 20g precursor Li 1.6 mn 1.6 o 4 , ultrasonically dispersed for 15 hours, plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com