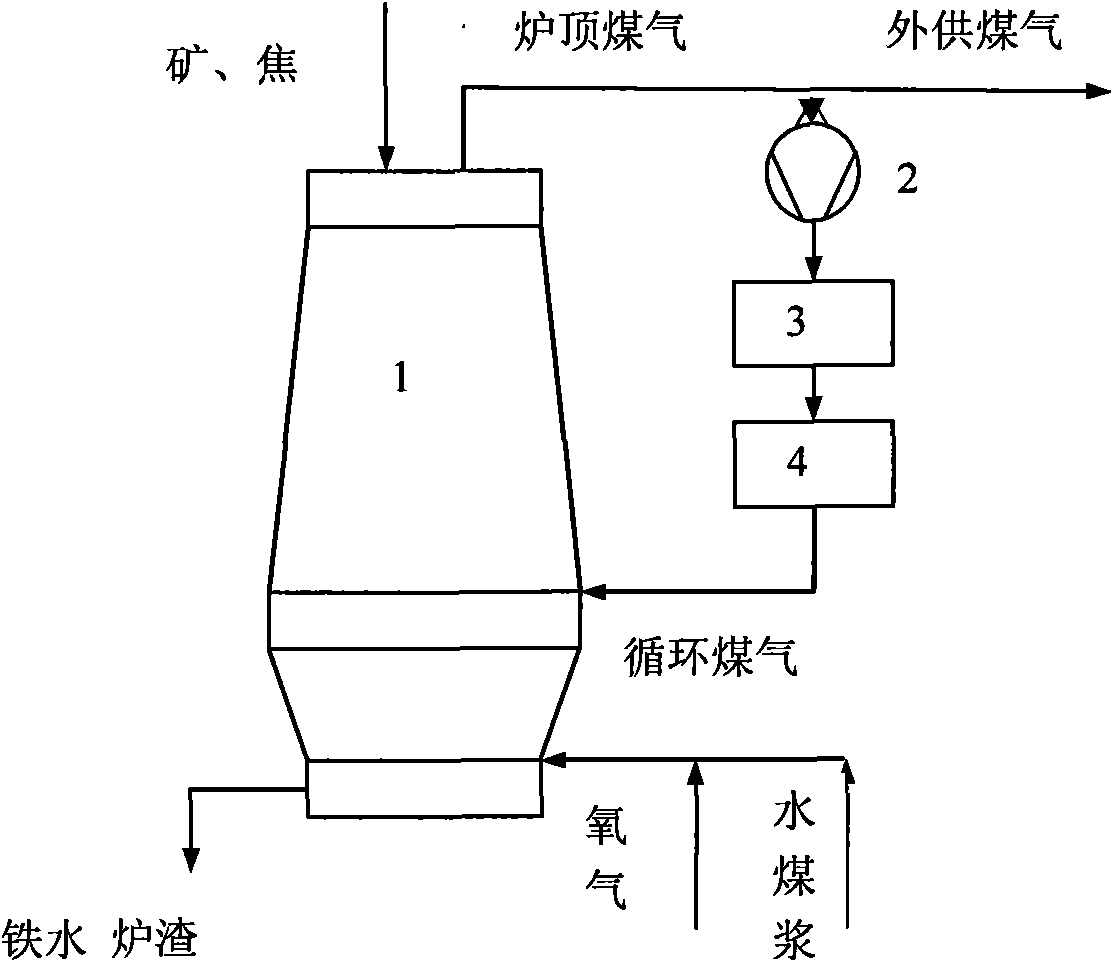

Oxygen blast furnace iron-making process adopting water-coal-slurry as fuel

A technology of blast furnace ironmaking and coal water slurry, which is applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of large emissions, pollution, and low productivity, and achieve the effects of eliminating pollution, reducing environmental pollution, and improving blast furnace productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

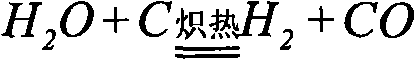

Method used

Image

Examples

Embodiment 1

[0030] Theoretical calculations show that 75%, 15% pellets and 10% lump ore are used as raw materials in the oxygen blast furnace, and coal-water slurry is injected from the tuyere and pure oxygen is blown in. The production technical indicators are as follows:

[0031] CWS dosage: 200kg / tHM

[0032] Oxygen consumption: 289m 3 / tHM

[0033] Coke ratio: 376kg / tHM

[0034] Furnace circulating gas volume: 278m 3 / tHM

[0035] Furnace circulation gas composition: H 2 : 21.37% CO: 77.91% N 2 : 0.72%

[0036] Bosh gas composition: H 2 : 23.51% CO: 75.77% N 2 : 0.72%

[0037] Bosh gas volume: 1113m 3 / tHM

[0038] Theoretical combustion temperature: 2050°C

[0039] Furnace top gas volume: 1552m 3 / tHM

[0040]Top gas composition: H 2 : 8.86% CO: 33.34% CO 2 : 48.72%H 2 O: 8.4% N 2 : 0.68%.

Embodiment 2

[0042] Theoretical calculations show that 75%, 15% pellets and 10% lump ore are used as raw materials in the oxygen blast furnace, and coal-water slurry is injected from the tuyere and pure oxygen is blown in. The production technical indicators are as follows:

[0043] CWS dosage: 250kg / tHM

[0044] Oxygen consumption: 311m 3 / tHM

[0045] Coke ratio: 350kg / tHM

[0046] Furnace circulating gas volume: 280m 3 / tHM

[0047] Furnace circulation gas composition: H 2 : 21.64% CO: 77.64% N 2 : 0.72%

[0048] Bosh gas composition: H 2 : 26.23% CO: 73.05% N 2 : 0.72%

[0049] Bosh gas volume: 1139m 3 / tHM

[0050] Theoretical combustion temperature: 2041°C

[0051] Furnace top gas volume: 1576m 3 / tHM

[0052] Top gas composition: H 2 : 8.93% CO: 33.20% CO 2 : 48.56%H 2 O: 8.60% N 2 : 0.71%.

Embodiment 3

[0054] Theoretical calculations show that 75%, 15% pellets and 10% lump ore are used as raw materials in the oxygen blast furnace, and coal-water slurry is injected from the tuyere and pure oxygen is blown in. The production technical indicators are as follows:

[0055] CWS dosage: 300kg / tHM

[0056] Oxygen consumption: 334m 3 / tHM

[0057] Coke ratio: 298kg / tHM

[0058] Furnace circulating gas volume: 281m 3 / tHM

[0059] Furnace circulation gas composition: H 2 : 21.77% CO: 77.50% N 2 : 0.73%

[0060] Bosh gas composition: H 2 : 27.41% CO: 71.86% N 2 : 0.73%

[0061] Bosh gas volume: 1151m 3 / tHM

[0062] Theoretical combustion temperature: 2041°C

[0063] Furnace top gas volume: 1598m 3 / tHM

[0064] Top gas composition: H 2 : 8.95% CO: 33.02% CO 2 : 48.72%H 2 O: 8.61% N 2 : 0.70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com