Method for recovering rhenium from molybdenum smelting waste acid

A waste acid and concentration technology, applied in chemical instruments and methods, preparation of rhenium compounds, rhenium compounds, etc., can solve the problems of complicated process operation and improvement of recovery rate, and achieve simple recovery process, long service life and shortened process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

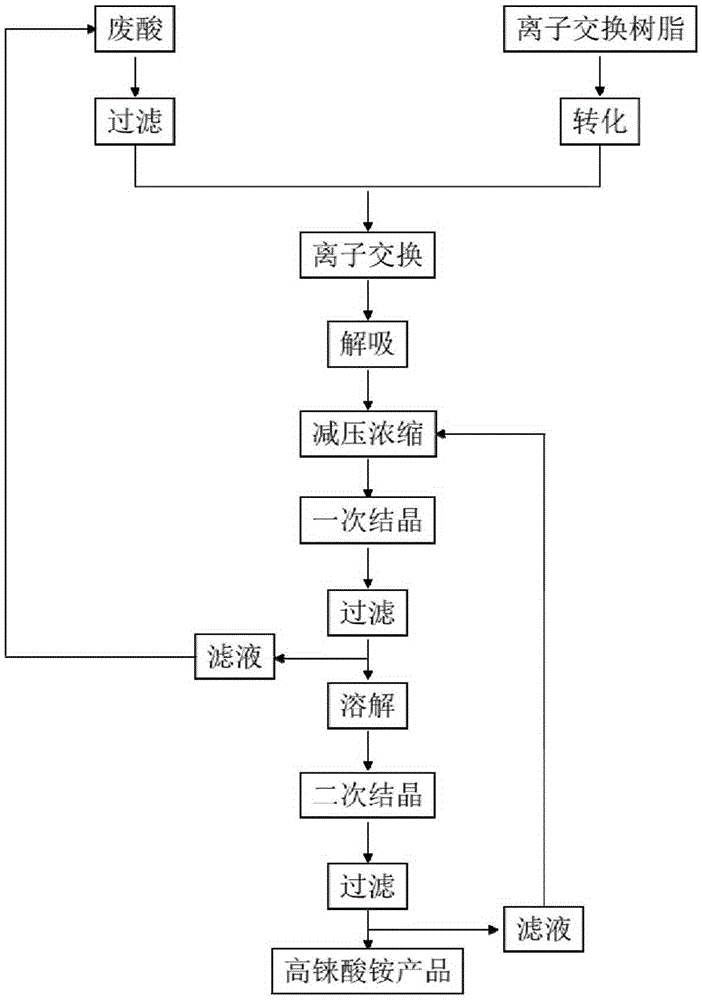

[0026] In this embodiment, the method for reclaiming rhenium from molybdenum smelting waste acid (the process flow diagram is shown in figure 1 ),Proceed as follows:

[0027] 1) Put 20L compound aminovinyl weak base anion exchange resin into 4 ion exchange columns (each column is filled with 5L resin), and connect them in series, first wash the resin with deionized water, and then use 60L Wash with 10% NaOH, 10% HCl, and finally use 100L of 5% H 2 SO 4 Resin is transformed, standby;

[0028] The preparation method of compound amino vinyl weak base anion exchange resin is as follows: put chlorine balls (purchased from Hebei Langfang Electric Power Resin Co., Ltd.) in water to swell for 1 hour and then filter out; Methylamine, N,N-dimethylaniline and dimethylamine hydrochloride, heat preservation reaction at 75°C for 7 hours, filter out the resin after the reaction, soak in dilute hydrochloric acid to make the soaking solution weakly acidic, and obtain a milky white spherical...

Embodiment 2

[0035] The method for reclaiming rhenium from molybdenum smelting waste acid in the present embodiment, the steps are as follows:

[0036] 1) Put 20L compound aminovinyl weak base anion exchange resin into 4 ion exchange columns (each column is filled with 5L resin), and connect them in series, first wash the resin with deionized water, and then wash it with 80L Wash with 8% NaOH and 8% HCl, and finally use 80L of 8% H 2 SO 4 Resin is transformed, standby;

[0037] The preparation method of compound amino vinyl weak base type anion exchange resin is as follows: put chlorine balls (purchased from Hebei Langfang Power Resin Co., Ltd.) into water to swell for 1 hour and then filter out, add 3:5:5:4 Methylamine, N,N-dimethylaniline and dimethylamine hydrochloride were kept at a temperature of 60°C for 10 hours. After the reaction, the resin was filtered out and soaked in dilute hydrochloric acid to make the soaking solution weakly acidic, and a milky white spherical shape was ob...

Embodiment 3

[0044] The method for reclaiming rhenium from molybdenum smelting waste acid in the present embodiment, the steps are as follows:

[0045] 1) Put 20L compound aminovinyl weak base anion exchange resin into 4 ion exchange columns (each column is filled with 5L resin), and connect them in series, first wash the resin with deionized water, and then use 100L Wash with 5% NaOH and 5% HCl, and finally use 60L of 10% H 2 SO 4 Resin is transformed, standby;

[0046] The preparation method of compound amino vinyl weak base type anion exchange resin is as follows: put chlorine balls (purchased from Hebei Langfang Power Resin Co., Ltd.) in water to swell for 1 hour and then filter out, add 3:3:7:2 Methylamine, N,N-dimethylaniline and dimethylamine hydrochloride were incubated at 90°C for 4 hours. After the reaction, the resin was filtered out and soaked in dilute hydrochloric acid to make the soaking solution weakly acidic to obtain a milky white spherical shape. Resin, the particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com