Intelligent collaborative deslagging method and system for zinc pot

A zinc slag and zinc pot technology, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problem of lack of synergy in the slag removal system, improve the slag removal efficiency and reduce the consumption of zinc solution , to avoid the effect of frequent slag fishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

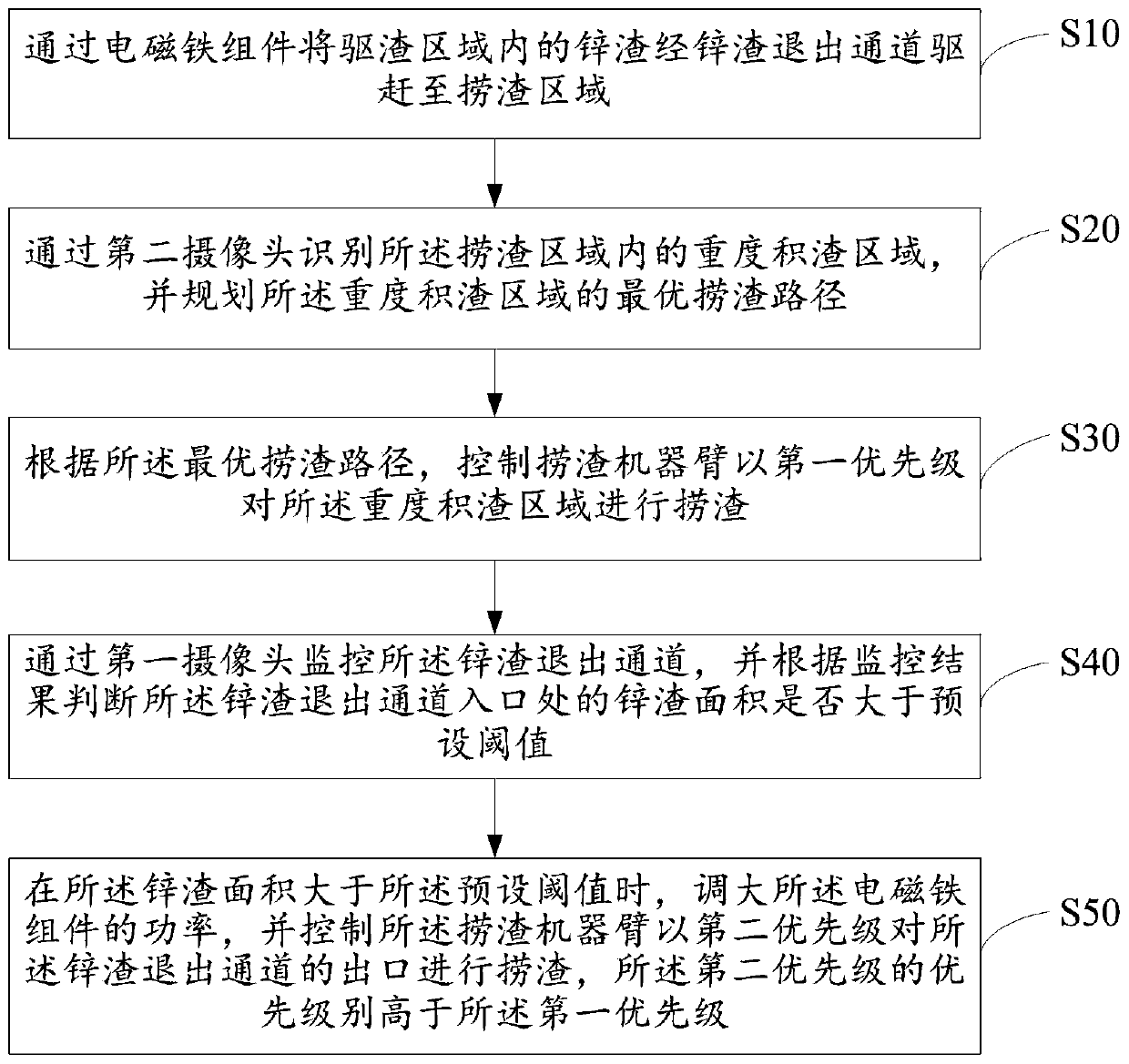

[0047] refer to figure 1 , figure 1 It is a schematic flow chart of an intelligent collaborative slag removal method for zinc pots in an embodiment of the present invention.

[0048] In this embodiment, the intelligent collaborative slag removal method for zinc pots is applied to electronic equipment, and the method includes:

[0049]Step S10: drive the zinc slag in the slag removal area to the slag removal area through the zinc slag exit channel through the electromagnet assembly.

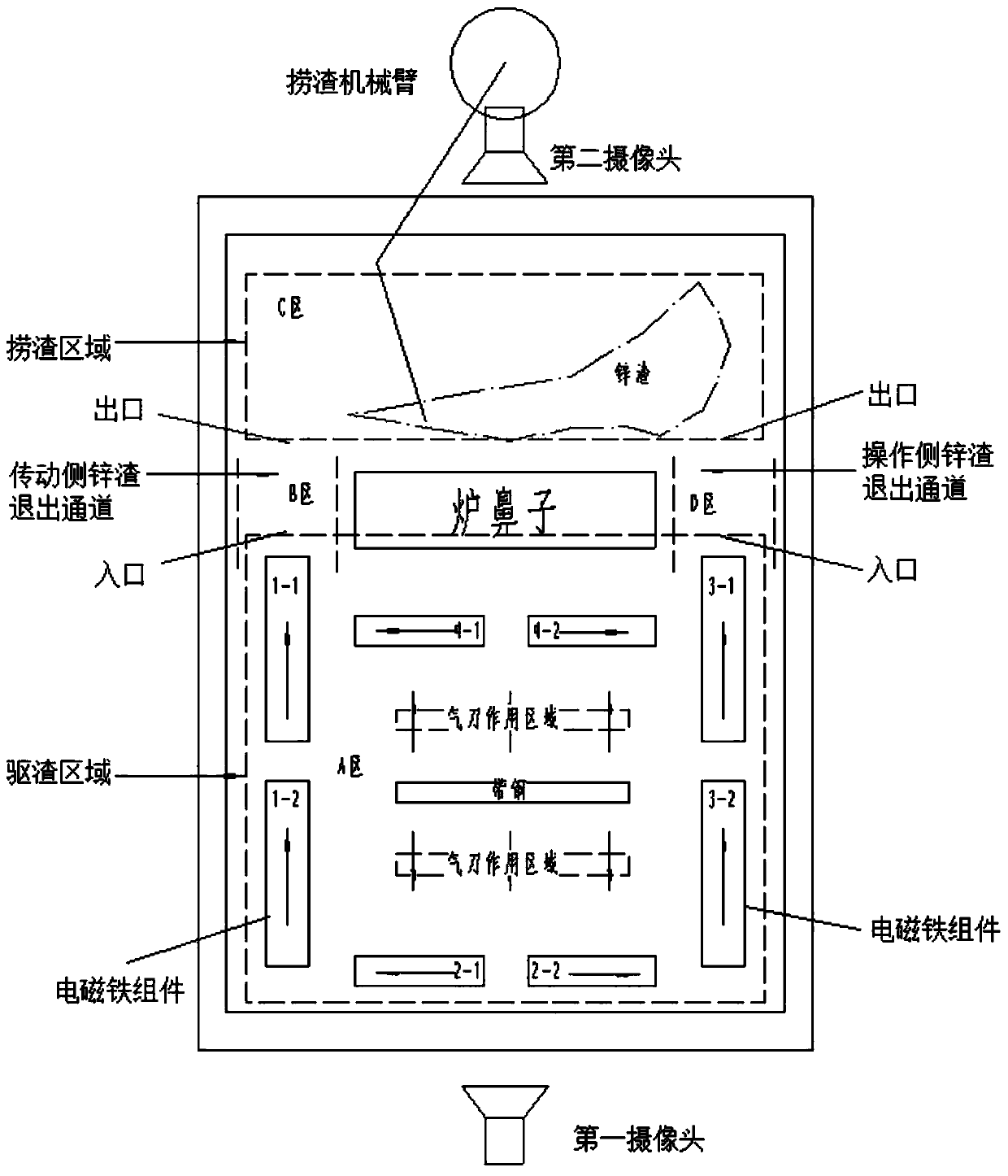

[0050] The execution subject of this embodiment is the electronic device, and the electronic device is generally an industrial control computer, and may also be a smart phone, a tablet computer, a personal computer, or a server, which is not limited in this embodiment. refer to figure 2 , the hot-dip galvanizing zinc pot is divided into slag driving area (A district), zinc slag exit channel (B district and D district) and slag removal district (C district) by furnace nose, and the hot-dip galv...

no. 2 example

[0074] Based on the same inventive idea, such as image 3 As shown, the embodiment of the present invention also provides a computer-readable storage medium 300, on which a computer program 311 is stored, and when the program 311 is executed by a processor, the following steps are implemented:

[0075] The zinc slag in the slag removal area is driven to the slag removal area through the zinc slag exit channel through the electromagnet assembly; the heavy slag accumulation area in the slag removal area is identified by the second camera, and the maximum time for the heavy slag accumulation area is planned Optimal slag removal path; according to the optimal slag removal path, control the slag removal robot arm to remove slag from the heavy slag accumulation area with the first priority; monitor the zinc slag exit channel through the first camera, and according to the monitoring As a result, it is judged whether the zinc dross area at the entrance of the zinc dross exit channel i...

no. 3 example

[0078] Based on the same inventive idea, such as Figure 4 As shown, the embodiment of the present invention also provides an electronic device 400, including a memory 410, a processor 420, and a computer program 411 stored in the memory 410 and operable on the processor 420, and the processor 420 executes the described Procedure 411 to implement the following steps:

[0079] The zinc slag in the slag removal area is driven to the slag removal area through the zinc slag exit channel through the electromagnet assembly; the heavy slag accumulation area in the slag removal area is identified by the second camera, and the maximum time for the heavy slag accumulation area is planned Optimal slag removal path; according to the optimal slag removal path, control the slag removal robot arm to remove slag from the heavy slag accumulation area with the first priority; monitor the zinc slag exit channel through the first camera, and according to the monitoring As a result, it is judged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com