Automatic skimming method and apparatus

A slag removal and automatic technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

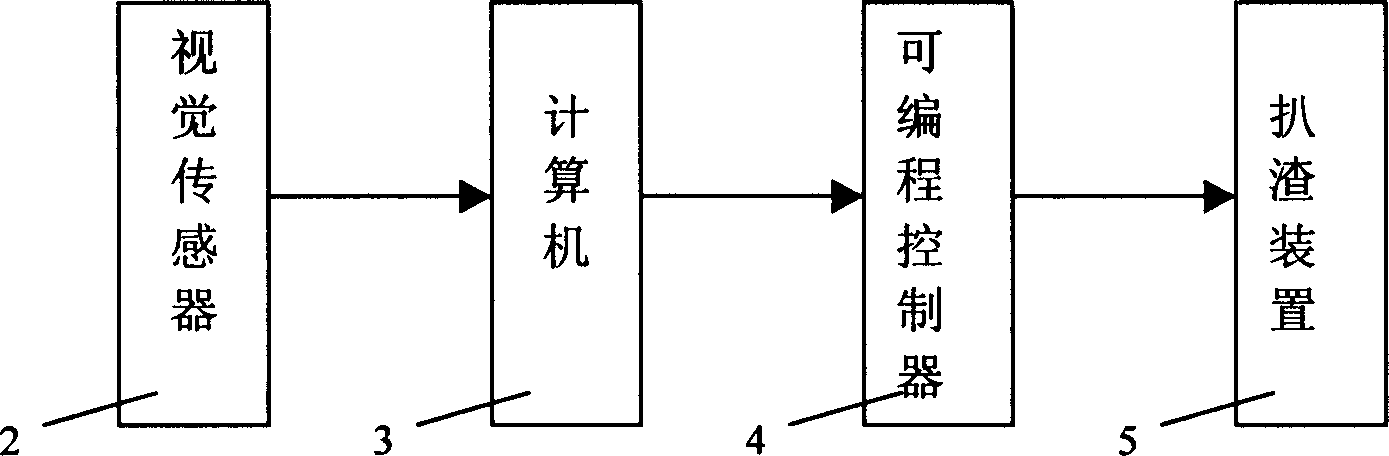

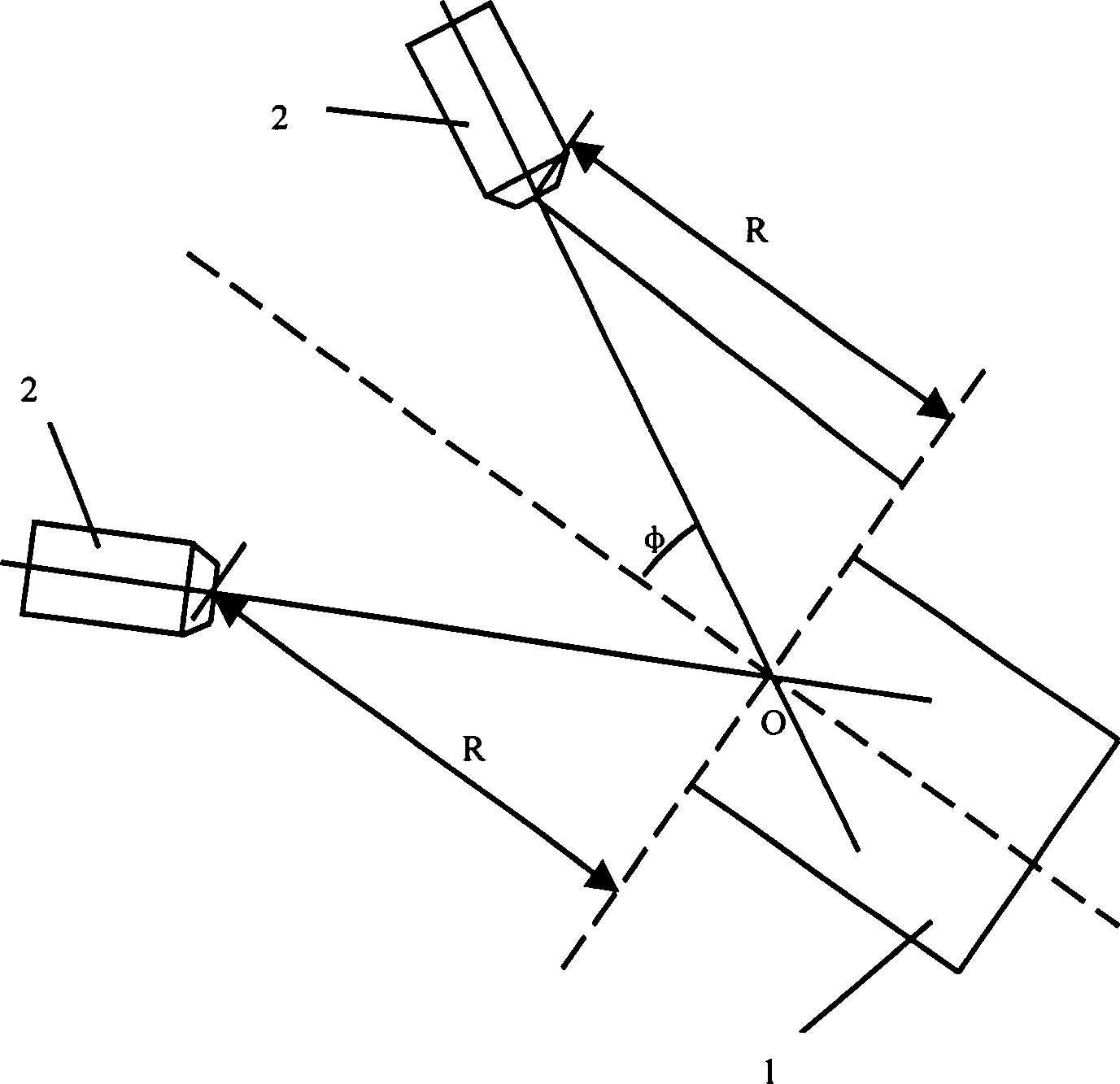

[0015] see figure 2 , image 3 , Figure 4 , an automatic slag removal method, which is to detect steel slag on the surface of ladle 1 by visual sensor 2, input the detected image into computer 3, and output signal to programmable controller 4 to control manipulator 5 of slag removal device after computer 3 processes the image. Slagging operation. The method of computer image processing and output control manipulator is:

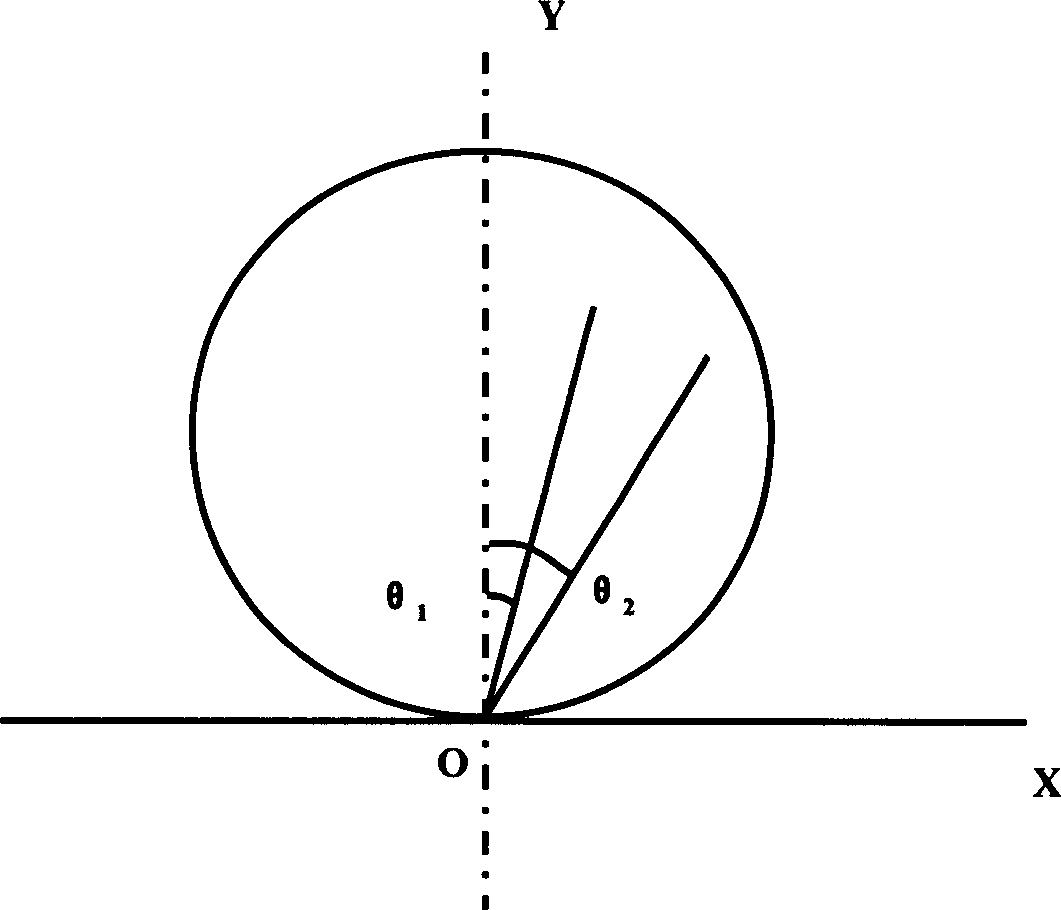

[0016] (1) First identify the target steel slag position, determine the steel slag position by pre-setting the surface partition, set the starting point as zero, the rotation angle as θ, the rotation angle and the surface Y axis form angles θ1, θ2,… θn, divide the surface into several fan-shaped areas, set the value of θ (-90°<θ<90°), then θ1=θ, θ2=2θ, θ3=3θ, θ4=4θ...θn=nθ, divide the entire surface area is n areas;

[0017] (2) Locate the target slag, and judge that the steel slag is at a certain position through the visual sensor;

[0018] (3) Judgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com