Slag blow-removal mechanism

A technology of slag removal machine and hinge mechanism, which is applied in the field of metallurgical equipment, can solve the problems of being unable to adapt to slag removal, and the number of furnaces operated by the gun head, etc., so as to shorten the operation time of slag removal, improve the efficiency of slag removal, and reduce the death of slag removal zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

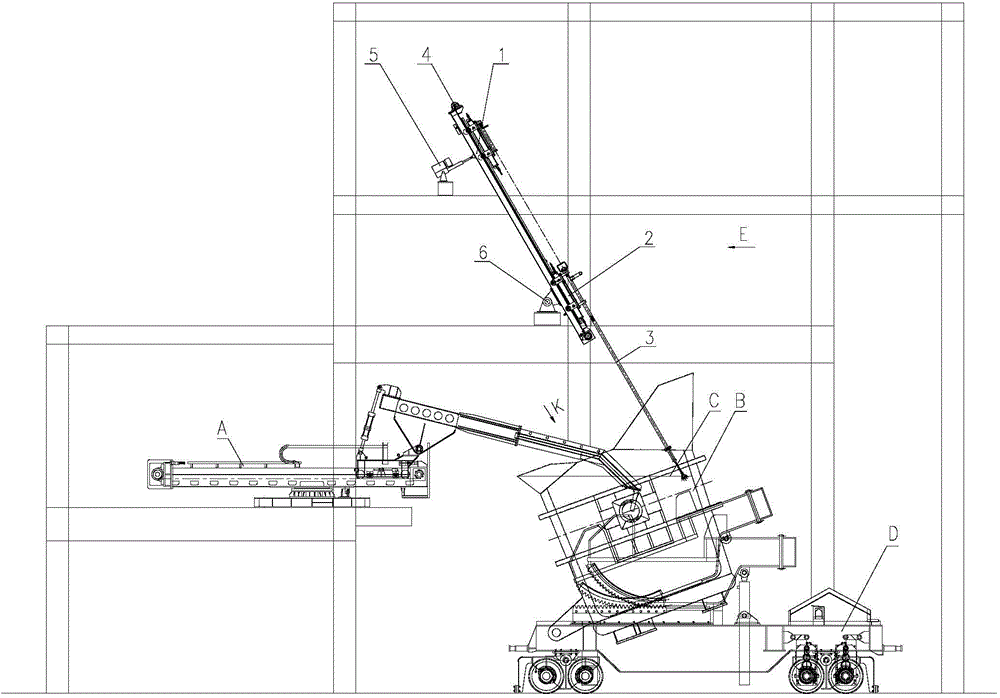

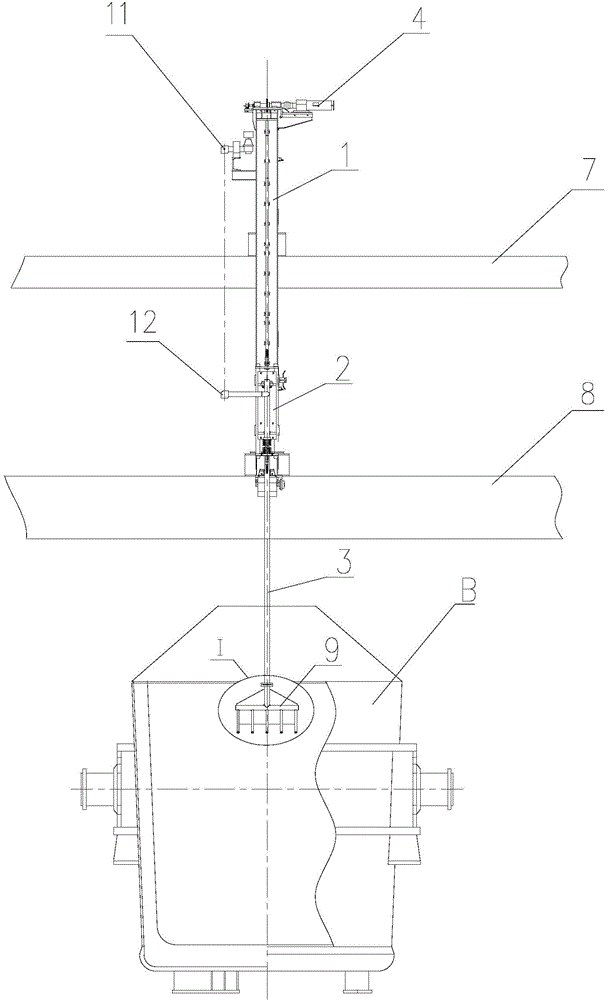

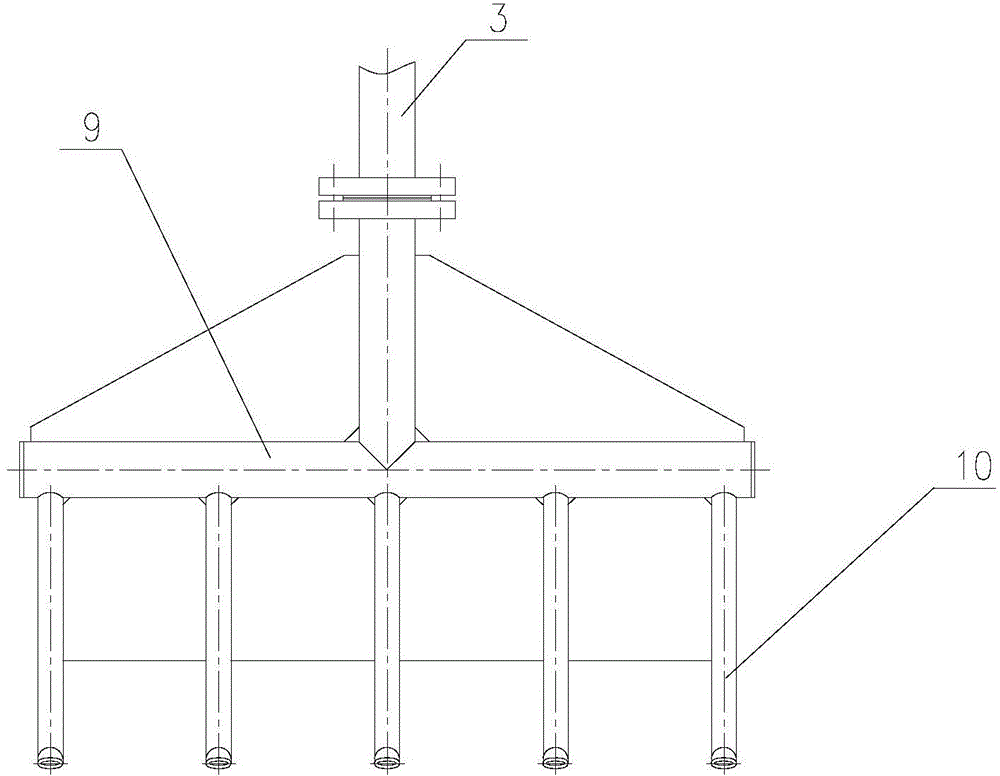

[0037] refer to figure 1 , in the figure, A is the slag removal machine, B is the molten iron tank, C is the slag surface of the molten iron tank, and D is the tipping vehicle of the molten iron tank. After a certain angle, the blowing slag removal mechanism lowers the gun, and the gun head extends above the molten iron level C of the molten iron tank B, blows nitrogen gas, and uses the reaction force of the molten iron level slag on the tank wall to drive the blast furnace slag or desulfurization slag into the The slag removal port of the slag removal machine A is used to remove the blast furnace slag or desulfurization slag in the molten iron tank through the slag removal machine A.

[0038] refer to figure 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com