Mud flushing circulation taphole system for shaft heading machine

The technology of roadheader and mud is applied in the field of scouring mud circulating slag system for shaft roadheaders, which can solve the problems of increasing the labor intensity of construction personnel, blocking the mud discharge port, affecting construction efficiency and reliability, etc. Reliability and automation, improving construction efficiency, and improving the effect of slagging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

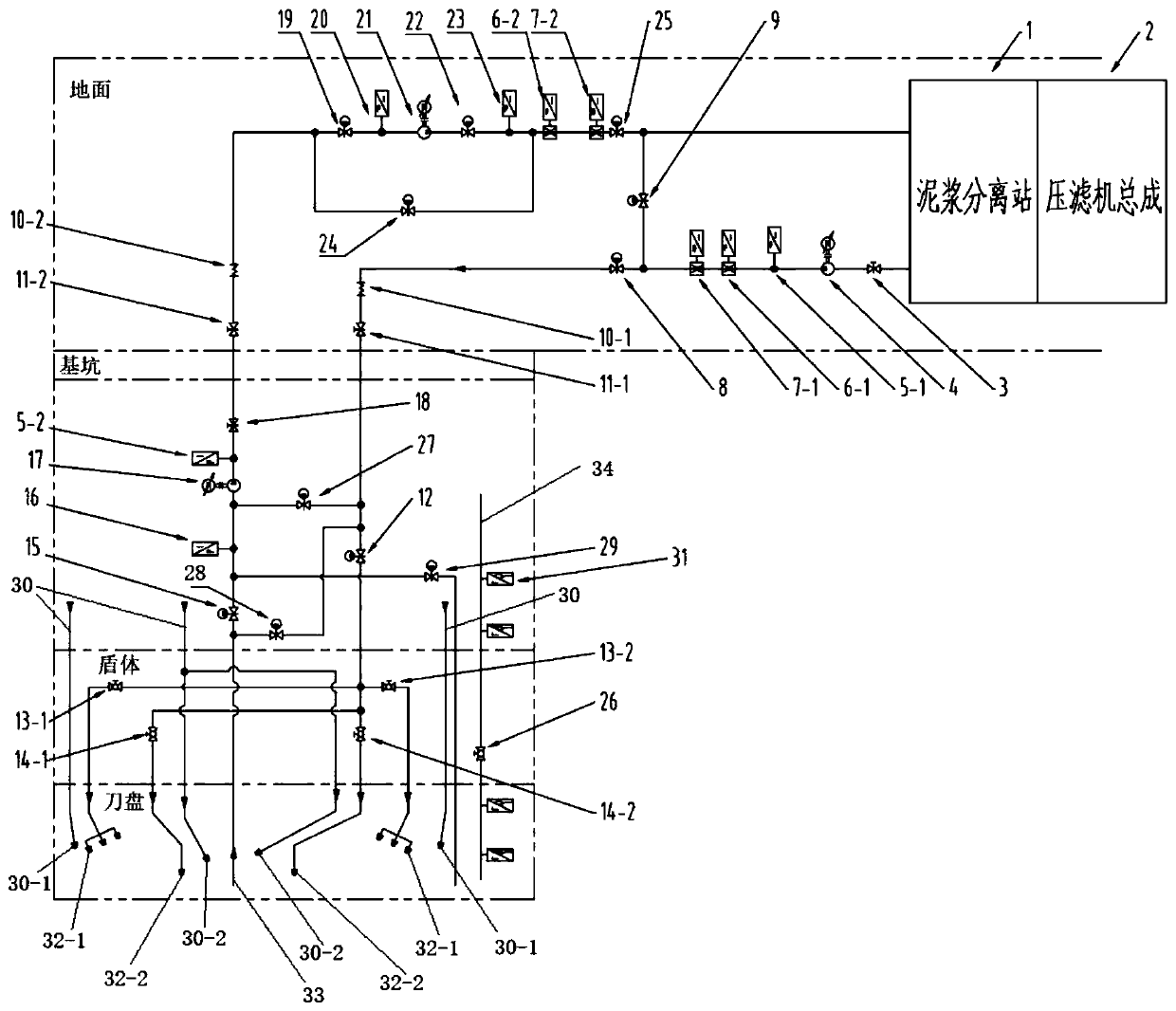

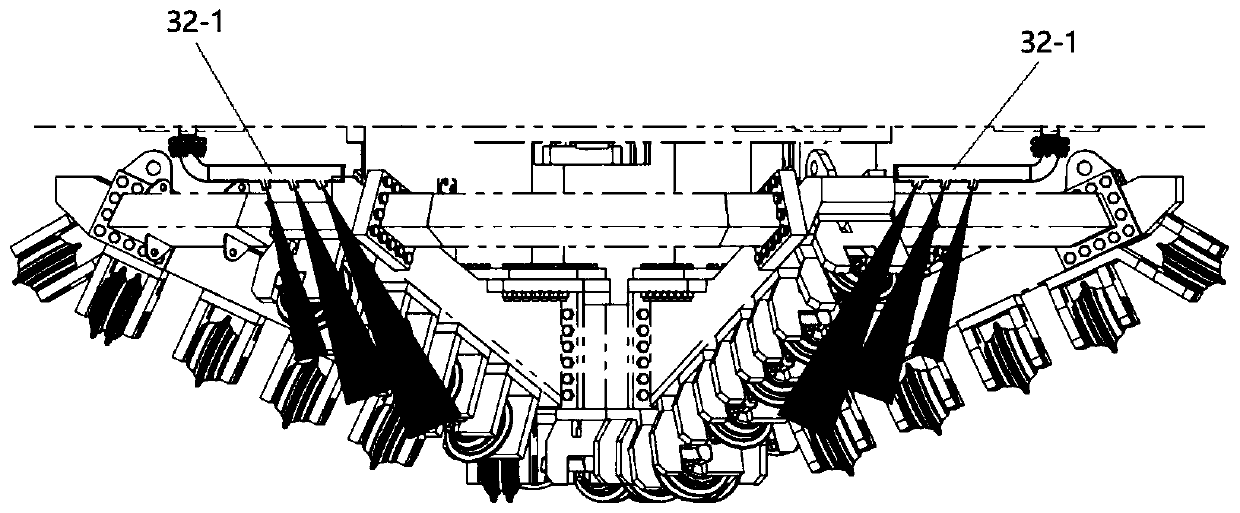

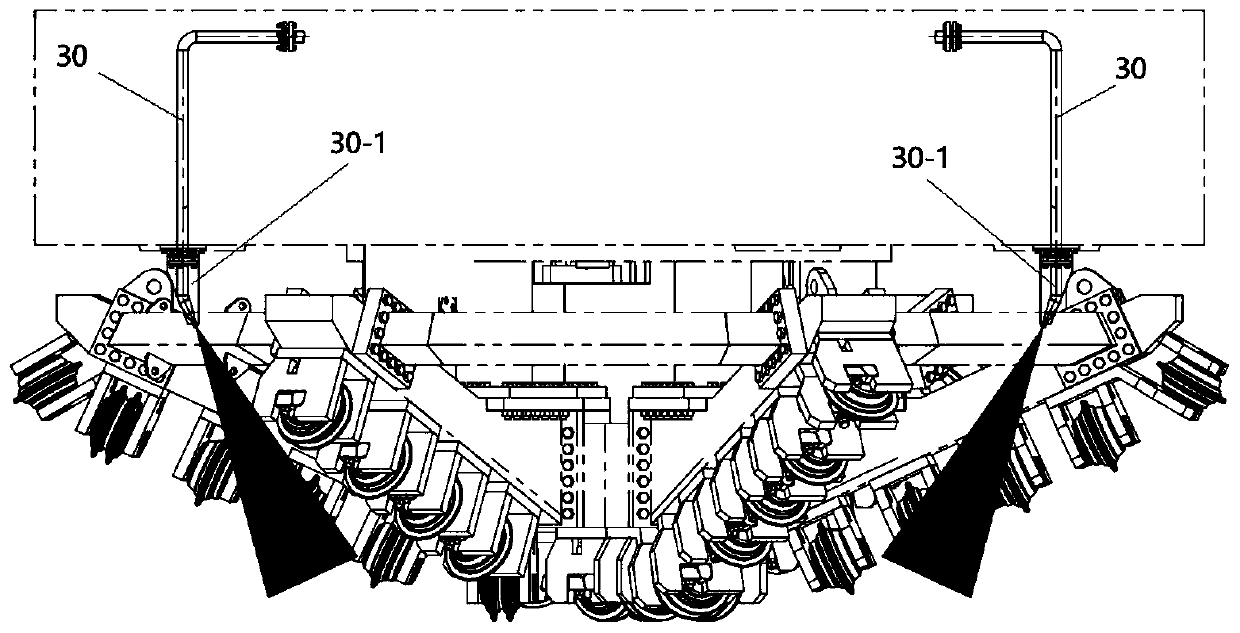

[0047] see Figure 1-5 , a flushing mud circulation and slag discharge system for a shaft boring machine, comprising a slurry inlet pipeline, a slurry discharge pipeline, a backwash pipeline and a mud treatment device, one end of the slurry inlet pipeline is connected to the mud treatment device, and the other end is arranged on the In the excavation chamber of the roadheader, it is used to transport the slurry treated by the mud treatment device to the excavation chamber. The slurry in the excavation bin is transported to the mud treatment device, and the circulation of the slurry between the excavation bin and the mud treatment device is realized through the cooperation of the slurry inlet pipeline and the slurry discharge pipeline;

[0048] The backwash pipeline includes a backwash slurry inlet branch and a backwash slurry discharge branch, and the backwash slurry inlet branch is connected to the slurry outlet 33 in the excavation bin and the slurry inlet pipeline, The slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com