Desander

A cyclone desanding and columnar technology, which is applied in the direction of the swirl axis can be reversed device, swirl device, etc., can solve the problems of waste of resources, frequent replacement, shortened service life, etc., to reduce labor intensity, The effect of reducing economic losses and reducing the number of sand discharges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

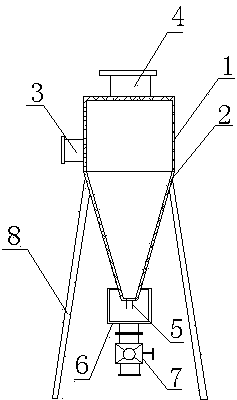

[0012] like figure 1 As shown, a cyclone desander includes a cylindrical barrel 1, a tapered barrel 2 and a bracket 8, the side wall of the cylindrical barrel 1 is equipped with a water inlet 3, and the top of the cylindrical barrel 1 is provided with There is an overflow water outlet 4, the bottom of the conical cylinder 2 is provided with a sewage outlet 5, and a sewage storage tank 6 is fixedly installed on the conical cylinder 2, and the sewage storage tank 6 communicates with the sewage discharge outlet 5. The bottom of the dirt storage tank 6 is fixedly connected with a shut-off valve 7 . The cylindrical barrel 1 and the tapered barrel 2 are ceramic barrels. The inner walls of the cylindrical barrel 1 and the tapered barrel 2 are in a spiral structure.

[0013] When working, the shut-off val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com