Slag conglomerating and skimming method and device

A slag removal and slag accumulation technology, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of low slag removal efficiency, high loss rate of molten iron, increase energy consumption per ton of steel, etc., and achieve accurate slag accumulation and slag removal. Operation, lower energy consumption, and high slag removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

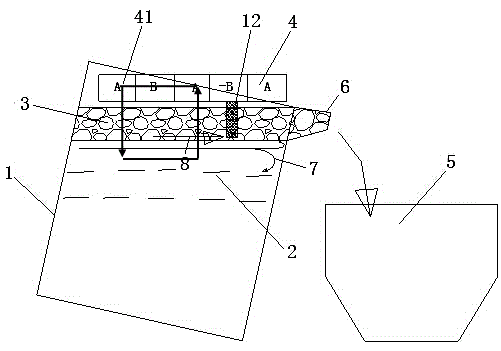

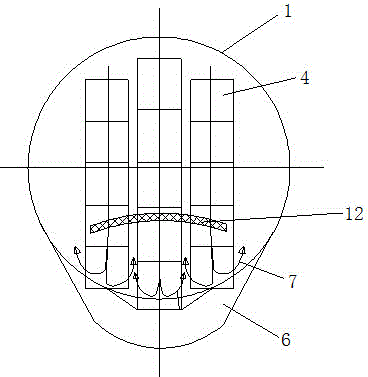

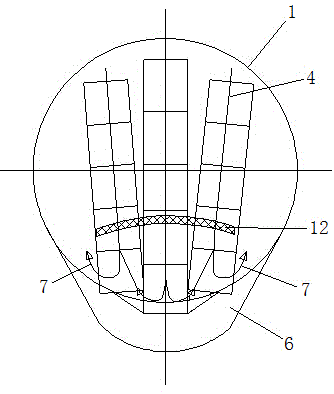

[0027] Such as figure 1 As shown, a method for collecting and removing slag, in which one or more groups of electromagnetic windings 4 are arranged above the ladle 1, through the phase control of the electromagnetic windings 4, the traveling wave magnetic field is excited, and through the control of the phase of the magnetic field, the line The moving direction of the molten iron 2 driven by the wave magnetic field points to the area where the molten iron ladle 6 is located, and the traveling wave magnetic field is used to generate an induced eddy current in the molten iron 2. At this time, the molten iron 2 is equivalent to the moving element of the linear motor, and the induced eddy current is generated in cooperation with the magnetic field. The Lorentz force makes the molten iron in the upper layer of the ladle 1 flow to the mouth of the ladle to form a moving streamline 8. When the molten iron 2 moves along the moving streamline 8 to the wall of the ladle, the backflow aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com