Water distributing plate used for high flow velocity equipment

A technology of water distribution board and high flow rate, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve problems such as multiple joint surfaces, partial flow, and poor sealing of joint surfaces, and achieve Uniform distribution of water, reducing wear and ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

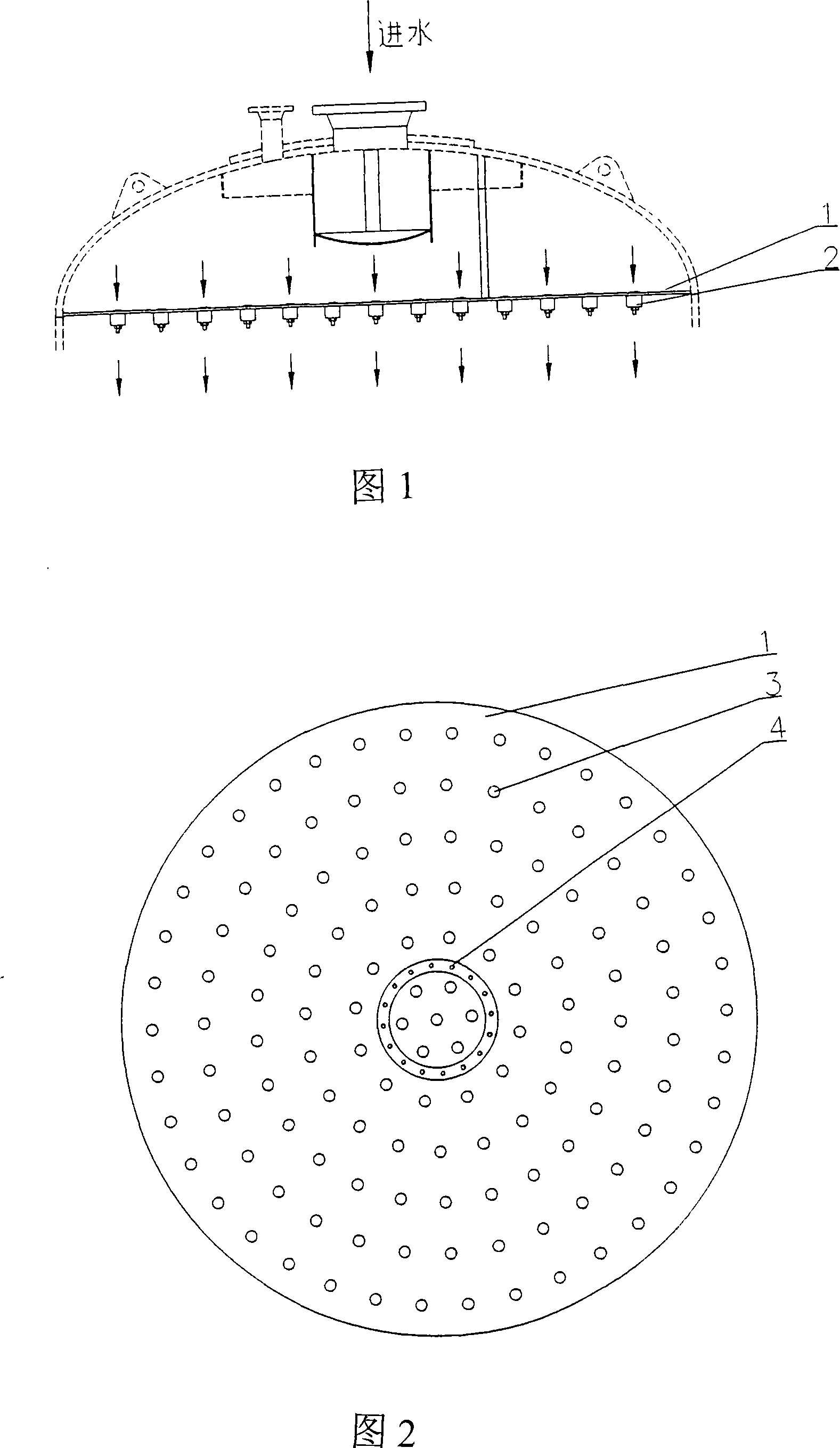

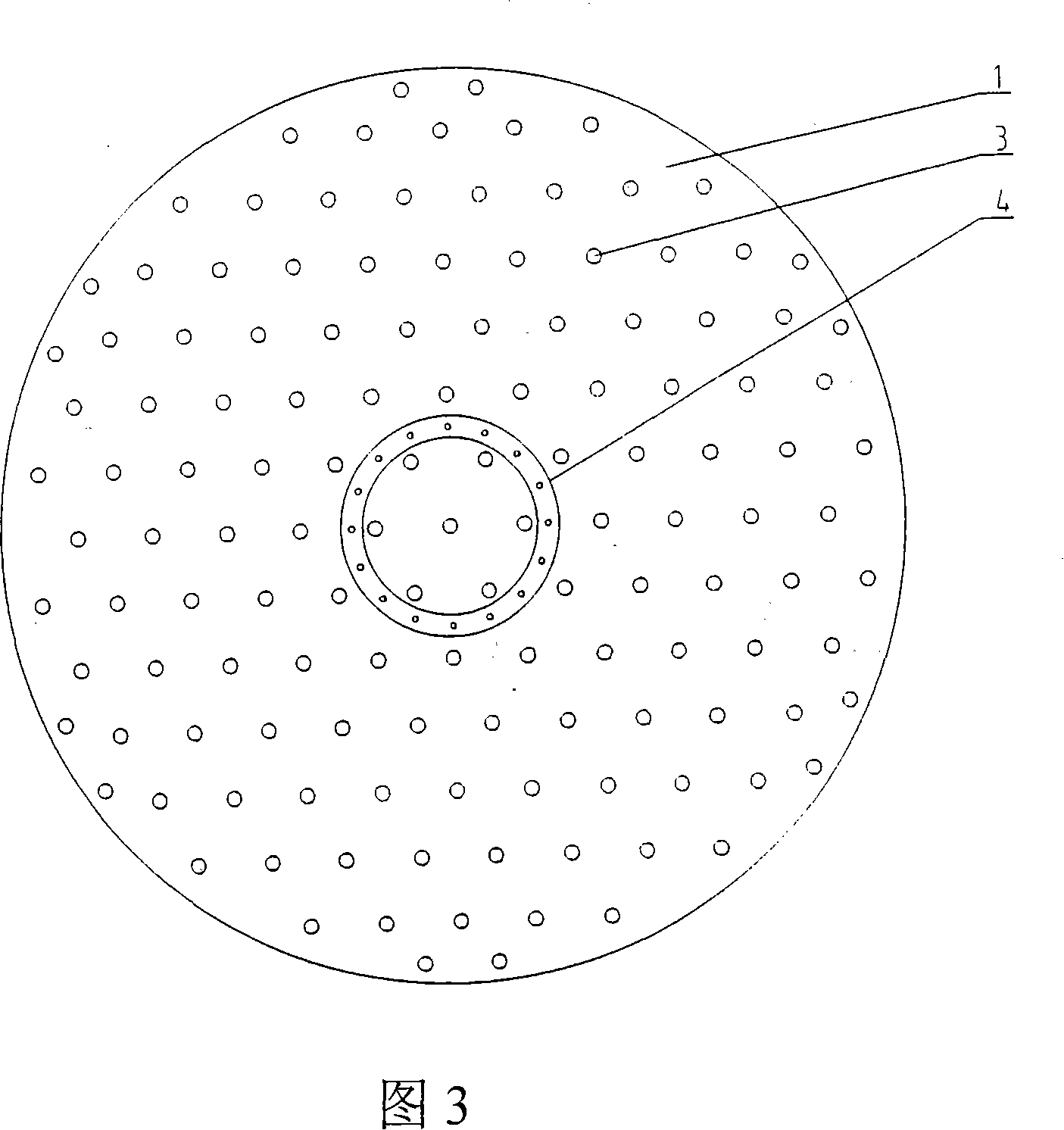

[0020] According to the installation size of the water distributor (water cap or faucet), a certain number of water distributor installation holes are designed on the circular plate. These installation holes are arranged in a certain method or rule according to the requirements of different flow rates to maximize the Make sure that the water distribution is even when the device is running. Its main features are that the overall structure is a circular perforated plate (non-bolt assembled structure); it is connected with the equipment body by welding; it cannot be disassembled; Restricted by the structure itself (such as assembled hem), it can be arranged flexibly and distributed more evenly.

[0021] The number of water distributors on the water distribution board is finally determined according to the output of the equipment, where mm is millimeters.

[0022] The diameter of the water distribution plate is 2000mm to 3600mm, and 3130mm is selected in this example; the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com