Deslagging smelting flux for smelting casting zinc alloy and preparation method thereof

A zinc alloy and flux technology, which is applied in the field of slag removal, refining flux and its preparation, can solve the problems of deteriorating working environment, increased alloy melting loss rate, and difficulty in obtaining zinc alloy structure, so as to improve casting performance, wear resistance and Improved corrosion resistance and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

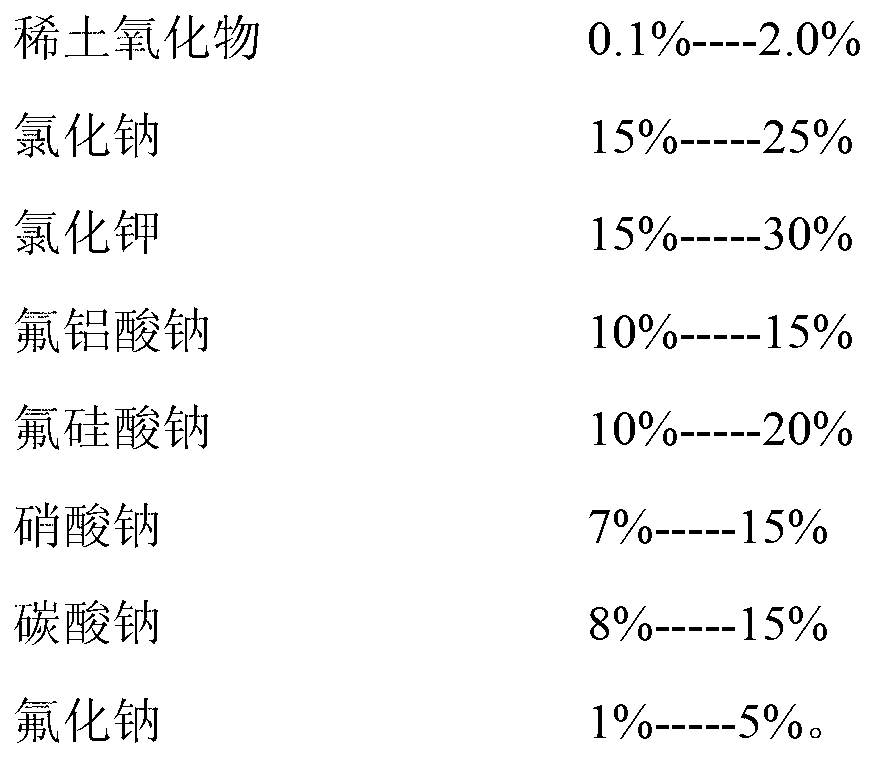

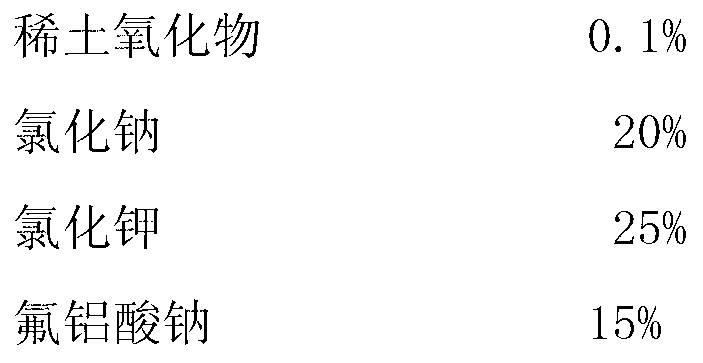

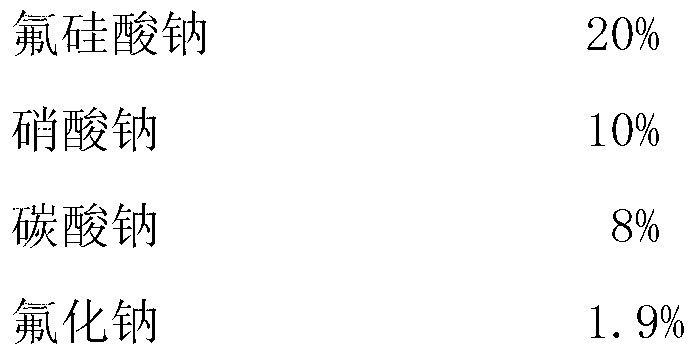

[0023]

[0024]

example 2

[0026]

example 3

[0028]

[0029] The rare earth oxide is lanthanum oxide, cerium oxide or praseodymium oxide, or a composition of the three oxides:

[0030] The weight content of lanthanum oxide is 20%-30%,

[0031] The weight content of cerium oxide is 65%-75%,

[0032] The weight content of praseodymium oxide is 2%-5%.

[0033] The preparation method of the slag-removing and refining flux for casting zinc alloy smelting comprises the following steps:

[0034] a) mixing sodium chloride, potassium chloride, sodium fluoroaluminate, sodium fluorosilicate and sodium fluoride at a temperature of 95°C-125°C and normal pressure for 45 minutes to form a uniform dry powder mixture;

[0035] b) Add sodium nitrate, sodium carbonate and rare earth oxides to the mixture, mix and stir for 30 minutes at a temperature of 85°C-100°C and normal pressure;

[0036] c) natural cooling and stirring for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com