Sintered flux for use in submerged-arc welding of nickel-based alloy and preparation method

A nickel-based alloy and sintered flux technology, which is applied in arc welding equipment, welding equipment, welding equipment, etc., can solve the problems of low mechanical properties of deposited metal, high impurity content, and unclean slag removal, and achieve stable welding specifications. The effect of low impurity content and smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

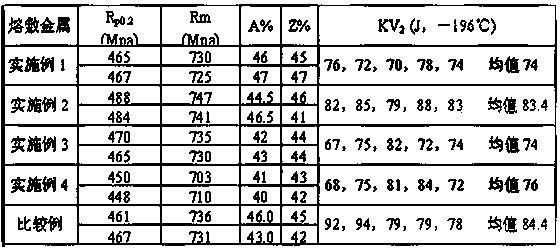

Embodiment 1

[0025] Put the weight percentage as: CaF 2 40%, Al 2 o 3 47%, CaCO 3 7%, metal aluminum powder 3%, sodium fluoroaluminate 3% flux dry powder composition, put into a mixer and fully dry mix, then add 20% potassium sodium 1:1 water glass with a viscosity of about 800MPa·S and fully wet mix, and then mix The wet material is put into a granulator for granulation, and the prepared flux granules are sent to a 350°C rotary drying furnace for 40min low-temperature drying, and then sent to a rotary sintering furnace for high-temperature sintering at a sintering temperature of 800°C. The sintering time is 40 minutes, cooled after coming out of the furnace, sieved out 20-mesh flux particles, packaged, and put into storage after passing the inspection, and the flux preparation is completed.

Embodiment 2

[0027] Put the weight percentage as: CaF 2 52%, Al 2 o 3 38%, CaCO 3 6%, metal aluminum powder 3%, sodium fluoroaluminate 1% flux dry powder composition, put it into a mixer and fully dry mix it, then add 30% potassium sodium 1:1 water glass with a viscosity of about 800MPa·S and fully wet mix it, and then mix it The wet material is put into a granulator for granulation, and the prepared flux granules are sent to a 350°C rotary drying furnace for 60 minutes of low-temperature drying. After drying, they are sent to a rotary sintering furnace for high-temperature sintering. The sintering temperature is 850°C. The sintering time is 30 minutes, cooled after coming out of the furnace, 40-mesh flux particles are screened out, packaged, and put into storage after passing the inspection, and the preparation of the flux is completed.

Embodiment 3

[0029] Put the weight percentage as: CaF 2 46%, Al 2 o 3 45%, CaCO 38%, 0.5% metal aluminum powder, 0.5% sodium fluoroaluminate flux dry powder composition, put it into a mixer and fully dry mix, then add 28% potassium sodium 1:1 water glass with a viscosity of about 800MPa·S and fully wet mix, and then mix The wet material is put into a granulator for granulation, and the finished flux granules are sent to a 370°C rotary drying furnace for 50 minutes of low-temperature drying. After drying, they are sent to a rotary sintering furnace for high-temperature sintering. The sintering temperature is 830°C. The sintering time is 40 minutes, cooled after coming out of the furnace, screened out 60-mesh flux particles, packaged, and put into storage after passing the inspection, and the flux preparation is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com