Rare earth contained deslagging and refining flux for smelting of cast aluminium alloy and preparation method of flux

A technology for casting aluminum alloy and flux, which is applied in the field of slag removal, refining flux and its preparation, and can solve problems such as a large amount of smoke and dust, deteriorating working environment, and increased alloy melting loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

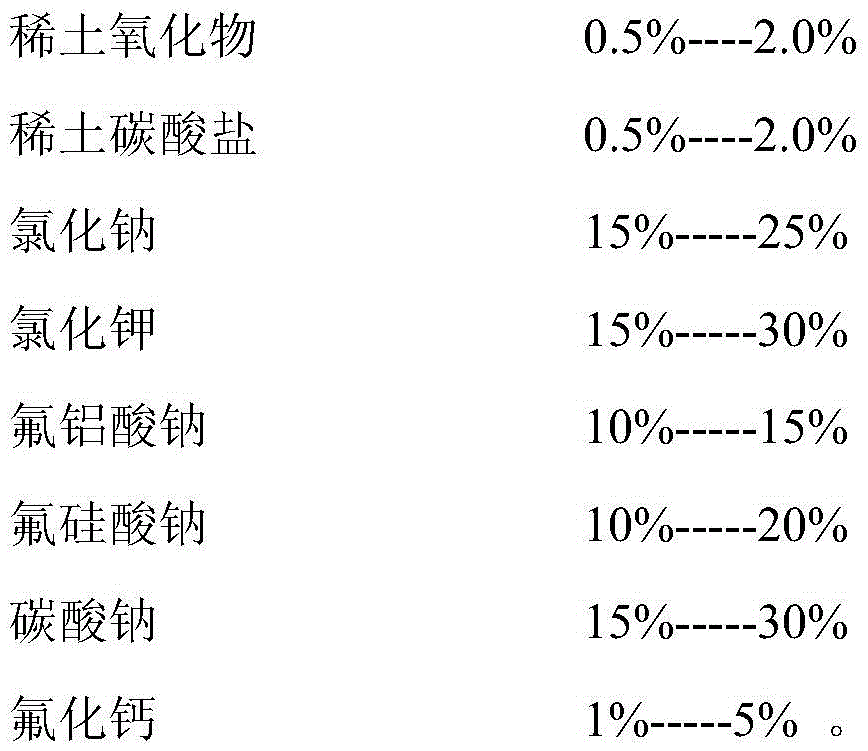

Method used

Image

Examples

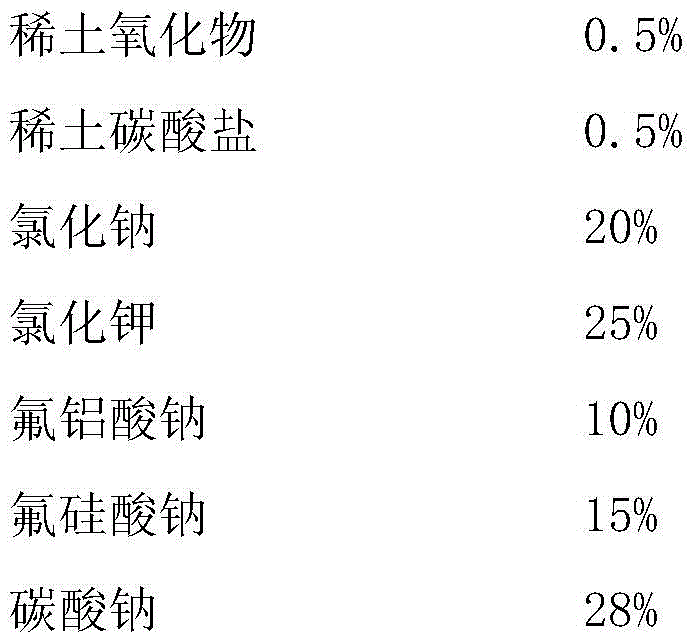

example 1

[0032]

[0033]

example 2

[0035]

example 3

[0037]

[0038] The rare earth oxide is lanthanum oxide, cerium oxide or praseodymium oxide, or a composition of the three oxides:

[0039] The weight content of lanthanum oxide is 25%-35%,

[0040] The weight content of cerium oxide is 60%-70%,

[0041] The weight content of praseodymium oxide is 2%-5%.

[0042] The rare earth carbonate is cerium carbonate or lanthanum carbonate.

[0043] The weight content of cerium carbonate is 70%-80%,

[0044] The weight content of lanthanum carbonate is 20%-30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com