Method for production of sodium aluminum fluoride

A technology of sodium fluoroaluminate and production method, which is applied in the chemical industry and can solve the problems of low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

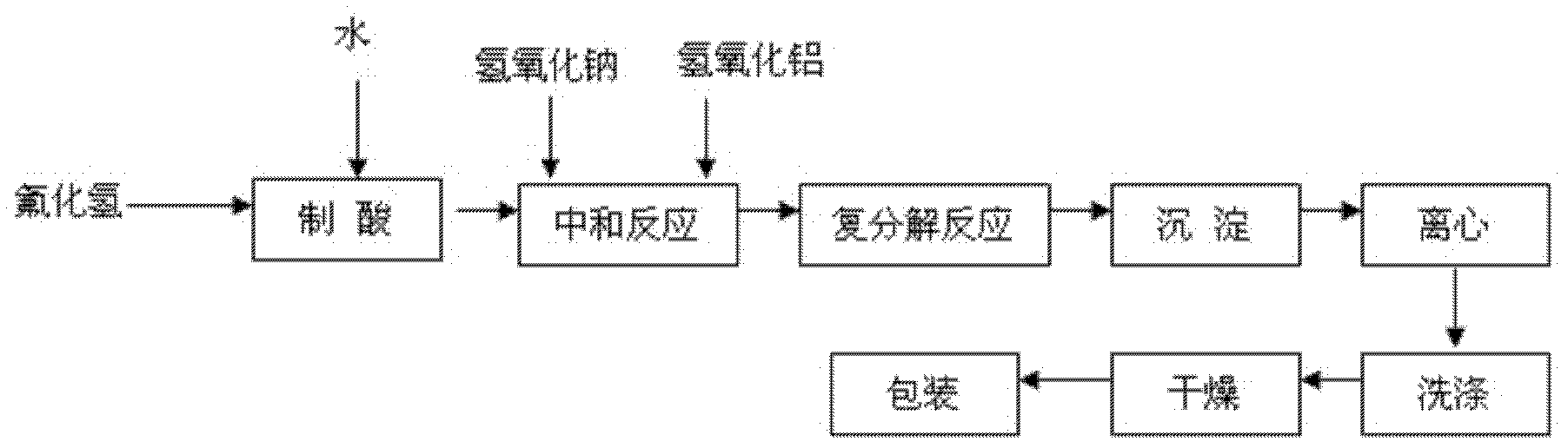

[0014] A kind of production method of sodium fluoroaluminate, it comprises the steps:

[0015] 1. Add 40kg of anhydrous hydrofluoric acid into 100kg of water, and dissolve at normal temperature and pressure to generate 140kg of hydrofluoric acid with a mass fraction of 40% for later use;

[0016] 2. Under normal temperature and pressure, add 7.8kg of aluminum hydroxide and 6kg of sodium hydroxide into the reaction tank and stir to generate 11.8kg of sodium metaaluminate;

[0017] 3. Get 100kg of spare 40% hydrofluoric acid in step 1 and add it into the reaction tank in step 2 to react with sodium metaaluminate to generate crude product;

[0018] 4. Precipitate, centrifuge, separate, wash and dry the crude product to obtain 65 kg of finished product with a yield of 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com