Method for recycling cryolite, calcium carbonate and sodium sulfate from calcium fluoride sludge resources

A technology of sodium sulfate and calcium fluoride, which is applied in the preparation of calcium carbonate/strontium/barium, aluminum fluoride, sulfate/bisulfate, etc., can solve the problems of high toxicity of hydrogen fluoride gas and complicated process conditions, and achieve conversion rate The effect of high recovery rate, easy large-scale production, and easy control of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

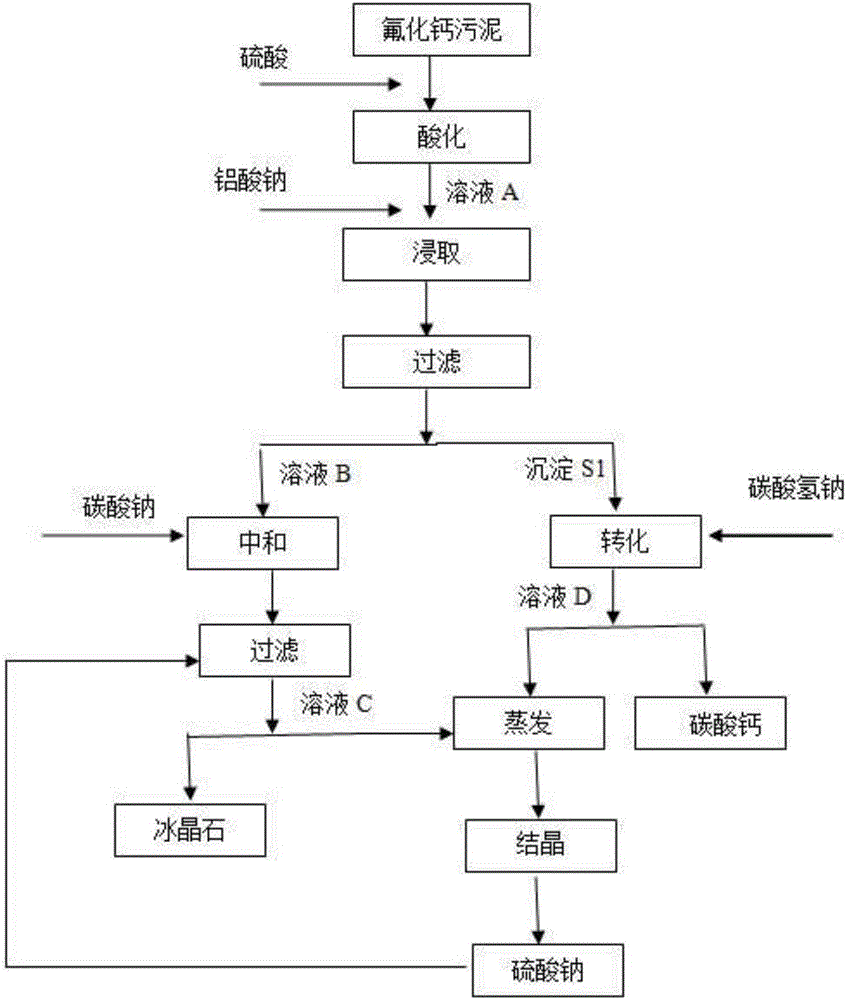

[0027] The applicant provides a method for reclaiming cryolite, calcium carbonate and sodium sulfate from calcium fluoride sludge resources, the specific steps are as follows:

[0028] (1) add sulfuric acid in calcium fluoride sludge 1000g, adjust its pH=2, when using sulfuric acid to acidify sludge, the time is 1.5h; Calcium that exists in the form of calcium hydroxide and calcium carbonate is converted into calcium sulfate to obtain solution A.

[0029] (2) Add 200g of sodium aluminate solid in solution A, and carry out stirring and leaching to convert calcium fluoride into fluoaluminic acid and calcium sulfate precipitation S1 and solution B;

[0030] (3) Sodium carbonate is added in solution B to make it pH=0.1, and 70g of sodium sulfate is added to promote the precipitation of sodium fluoroaluminate completely, and the stirring time is 1h to obtain 100g of cryolite and solution C; the amount of sodium carbonate is 1.3 of calcium sulfate times.

[0031] (4) Add 100mL 20w...

Embodiment 2

[0035] The applicant provides a method for reclaiming cryolite, calcium carbonate and sodium sulfate from calcium fluoride sludge resources, the specific steps are as follows:

[0036] (1) Add sulfuric acid to 1000 g of calcium fluoride sludge to adjust its pH=1. When sulfuric acid is used to acidify the sludge, the time is 1 hour; the calcium existing in the form of calcium hydroxide and calcium carbonate in the sludge is converted into sulfuric acid Calcium, to obtain solution A.

[0037] (2) Add 285g of sodium aluminate solid in solution A, and carry out stirring and leaching to convert calcium fluoride into fluoaluminic acid and calcium sulfate precipitation S1 and solution B;

[0038] (3) Sodium carbonate is added in solution B to make it pH=1, and 30g of sodium sulfate is added to impel the precipitation of sodium fluoroaluminate completely, and the stirring time is 1.5h to obtain 100g of cryolite and solution C; the amount of sodium carbonate is that of calcium sulfate ...

Embodiment 3

[0043] The applicant provides a method for reclaiming cryolite, calcium carbonate and sodium sulfate from calcium fluoride sludge resources, the specific steps are as follows:

[0044] (1) Add sulfuric acid to 1000 g of calcium fluoride sludge to adjust its pH=3. When using sulfuric acid to acidify the sludge, the time is 2 hours; the calcium existing in the form of calcium hydroxide and calcium carbonate in the sludge is converted into sulfuric acid Calcium, to obtain solution A.

[0045] (2) Add 500g of sodium aluminate solid in solution A, and carry out stirring and leaching to convert calcium fluoride into fluoaluminic acid and calcium sulfate precipitation S1 and solution B;

[0046] (3) Add sodium carbonate to solution B to make it pH=2, and add 50g of sodium sulfate to promote the complete precipitation of sodium fluoroaluminate, and stir for 2 hours to obtain 100g of cryolite and solution C; the amount of sodium carbonate is 1.5 of calcium sulfate times.

[0047] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com