A kind of method that reclaims lead, silver, indium from lead-silver slag

A technology of lead-silver slag and lead plate, which is applied in the fields of indium, lead and silver recycling, can solve the problems of hidden environmental hazards, low recovery rate, and high recovery cost, and achieve the effects of low environmental pollution, high recovery rate, and low recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

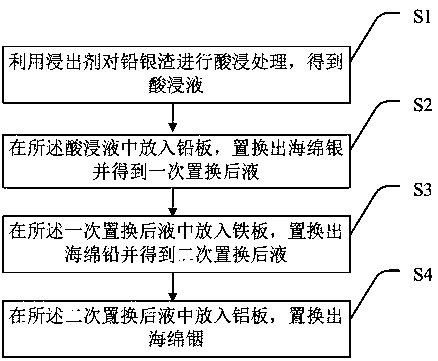

[0047] Put the lead and silver slag into the AlCl 3 250g / L, NaCl 90g / L, CaCl 2 70g / L, HCl 19.5g / L leaching agent, use HCl to control the pH of the system to 7.5, and carry out acid leaching treatment at 90°C for 180min to obtain the acid leaching solution;

[0048] Then put excess lead plates into the acid dipping solution at a temperature of 55°C to replace the sponge silver and obtain a replacement solution;

[0049] Then, at 75°C, put excess iron plates into the liquid after the first replacement to replace the sponge lead and obtain the liquid after the second replacement;

[0050] Then put excess aluminum plates into the liquid after the second replacement at a temperature of 20°C to replace the indium sponge and obtain the liquid after the third replacement;

[0051] The component analysis of sponge silver, sponge lead, sponge lead and the solution after three replacements shows that the direct recovery rate of silver is 98.54%, and the sponge silver contains 96.36% of...

Embodiment 2

[0053] Put the lead and silver slag into the AlCl 3 50g / L, NaCl 356g / L, CaCl 2 70g / L, HCl 19.5g / L leaching agent, use HCl to control the pH of the system to 7.3, and carry out acid leaching treatment at 85°C for 150min to obtain an acid leaching solution;

[0054] Then put excess lead plates into the pickling solution at a temperature of 50°C to replace the sponge silver and obtain a replacement solution;

[0055] Then, at 70°C, put excess iron plates into the liquid after the first replacement to replace the sponge lead and obtain the liquid after the second replacement;

[0056] Then put excess aluminum plates into the liquid after the second replacement at a temperature of 20°C to replace the indium sponge and obtain the liquid after the third replacement;

[0057] The component analysis of sponge silver, sponge lead, sponge lead and liquid after three replacements shows that the direct recovery rate of silver is 91.24%, and the sponge silver contains 90.35% silver; the...

Embodiment 3

[0059] Put the lead and silver slag into the AlCl 3 50g / L, NaCl 90g / L, CaCl 2 319g / L, HCl 19.5g / L leaching agent, use HCl to control the pH of the system to 7.8, and carry out acid leaching treatment at 95°C for 200min to obtain an acid leaching solution;

[0060] Then put excess lead plates into the pickling solution at 60°C to replace the sponge silver and obtain a replacement solution;

[0061] Then, at 80°C, put excess iron plates into the liquid after the first replacement to replace the sponge lead and obtain the liquid after the second replacement;

[0062] Then put excess aluminum plates into the liquid after the second replacement at a temperature of 30°C to replace the indium sponge and obtain the liquid after the third replacement;

[0063] The component analysis of sponge silver, sponge lead, sponge lead and liquid after three replacements shows that the direct recovery rate of silver is 97.34%, and the sponge silver contains 95.76% silver; the direct recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com