A method for recovering valuable metals from waste ternary lithium ion battery cathode materials

A technology for lithium ion batteries and cathode materials, which is applied in the field of recovering valuable metals from cathode materials of waste ternary lithium ion batteries, can solve the problem that solid reducing agents are easy to introduce impurities, unfavorable to large-scale industrial production, and low mass transfer and heat transfer efficiency. problems, to achieve the effect of facilitating large-scale continuous industrial production, simple and efficient heat balance, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

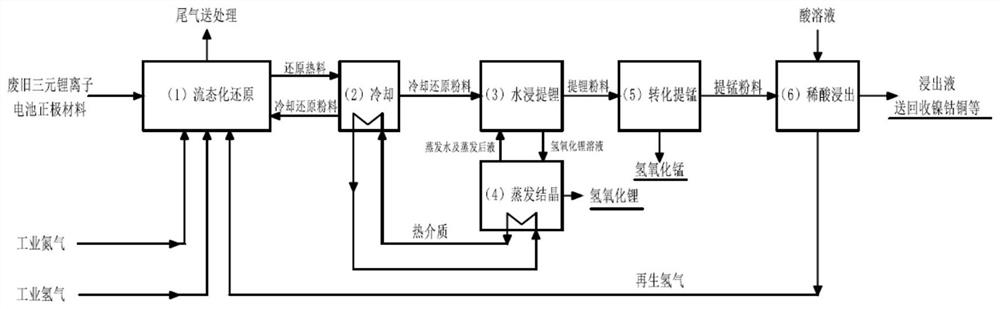

[0032] figure 1 It is a schematic flow chart of the method for recovering valuable metals from waste ternary lithium-ion battery cathode materials.

[0033] combine figure 1 , a method for recovering valuable metals from waste ternary lithium-ion battery cathode materials used in this embodiment, the method includes fluidized reduction process 1, cooling process 2, water leaching lithium process 3, evaporation and crystallization Operation 4, conversion and extraction of manganese operation 5 and dilute acid leaching operation 6 six operations, specifically carried out in the following steps:

[0034] 1) The positive electrode material of the waste ternary lithium-ion battery undergoes a fluidized reduction process to realize the transformation of the phase and structure, the reduction tail gas is sent for treatment, and the reduction heat material enters the cooling process;

[0035] 2) In the cooling process, the reduction heat material is exchanged with a heat medium to o...

Embodiment 2

[0041]This embodiment adopts the method for recovering valuable metals from the positive electrode material of the waste ternary lithium-ion battery described in Embodiment 1. The fluidized reduction process 1 adopts a fluidized bed reactor, the operating temperature is 300 ° C, and the reducing gas is hydrogen. The fluidization gas is a mixture of industrial nitrogen and hydrogen, the partial pressure of hydrogen is 0.1, and the residence time is 120min. The temperature of the cooled and reduced powder obtained in the cooling process is 40° C., the heat exchange medium is water, and the ratio of the cold material returned to the fluidized reduction process to the total cooled and reduced powder is 0.5. The operating temperature of the water leaching lithium extraction process is 20°C, the liquid-solid ratio is 5:1, the reaction time is 120min, and the liquid-solid separation adopts a belt filter, and the lithium leaching rate is 95%. The supporting electrolyte in the conversi...

Embodiment 3

[0043] This embodiment adopts the method for recovering valuable metals from waste ternary lithium-ion battery cathode materials described in Embodiment 1. The fluidized reduction process 1 adopts a fluidized bed reactor with an operating temperature of 700° C., and the reducing gas is hydrogen. The fluidizing gas is a mixture of industrial nitrogen and hydrogen, the partial pressure of hydrogen is 0.8, and the residence time is 15 minutes. The temperature of the cooled and reduced powder obtained in the cooling process is 90° C., the heat exchange medium is heat transfer oil, and the ratio of the cold material returned to the fluidized reduction process to the total cooled and reduced powder is 0.1. The operating temperature of the water leaching lithium extraction process is 90°C, the liquid-solid ratio is 2:1, and the reaction time is 10 minutes. The liquid-solid separation adopts a plate and frame filter press, and the lithium leaching rate is 96%. The supporting electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com