A treatment method for separating and recovering copper, iron, zinc, nickel and chromium from chromium-containing sludge

A treatment method, separation and recovery technology, applied to the separation and recovery of copper, iron, zinc, chromium from chromium-containing sludge, and the field of nickel, which can solve the problems of cumbersome steps and high requirements for supporting facilities, so as to reduce the content of chromium , the effect of reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

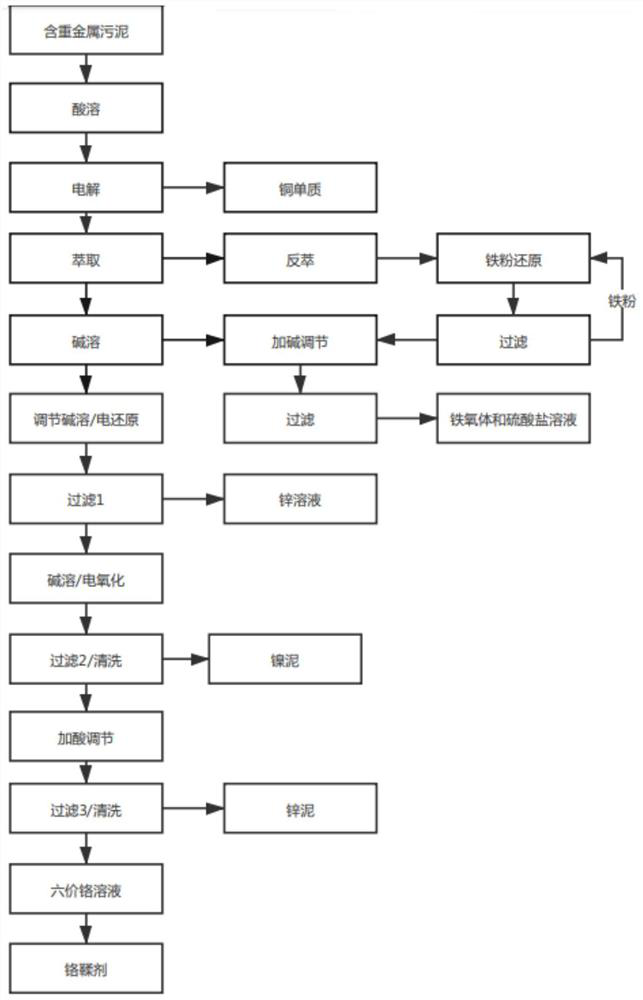

Method used

Image

Examples

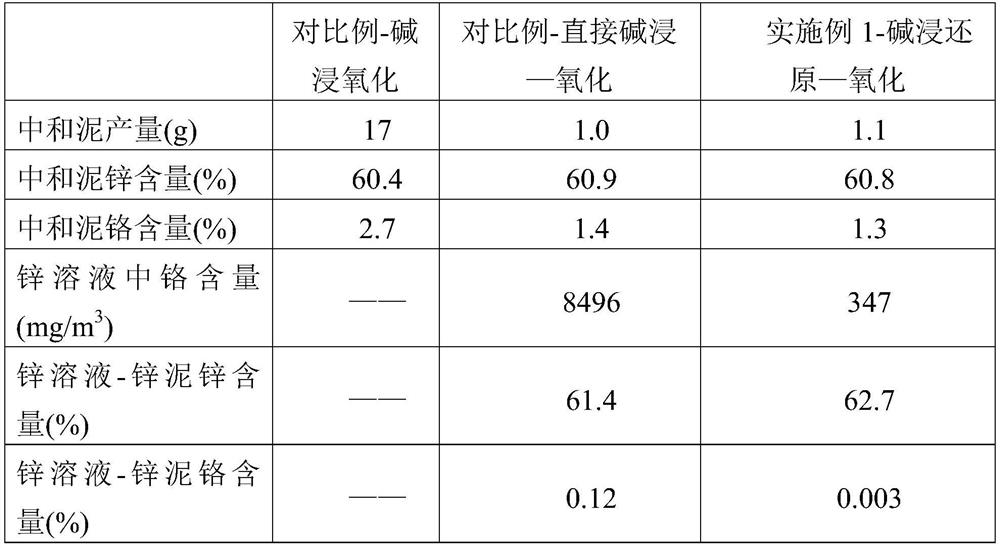

Embodiment 1

[0036] The chromium-containing sludge in a factory area contains 20% chromium, 10% zinc, 5% Cu, 1% Fe, and 1% Ni. Add sulfuric acid to 100g of chromium-containing sludge to dissolve completely, the concentration of acid added is 10%, and the amount of acid added is 400g. After electrolyzing the acid-dissolved solution for 24 hours, the copper in the solution was removed, and the concentration of copper ions in the solution was 37 mg / m 3 , 4.8g copper elemental substance was recovered. And use the extraction method to remove the iron in the solution, the iron ion concentration in the solution is 49mg / m 3 . After back-extracting the iron extract, a solution of ferric iron is obtained, and after reduction with excess reduced iron powder, a ferrous sulfate solution is obtained. Add 10% sodium hydroxide to the solution to adjust the pH value to 9, and filter to obtain sludge and high-salt solution. Add ferrous sulfate to the high-salt solution, adjust the pH value to 11, heat a...

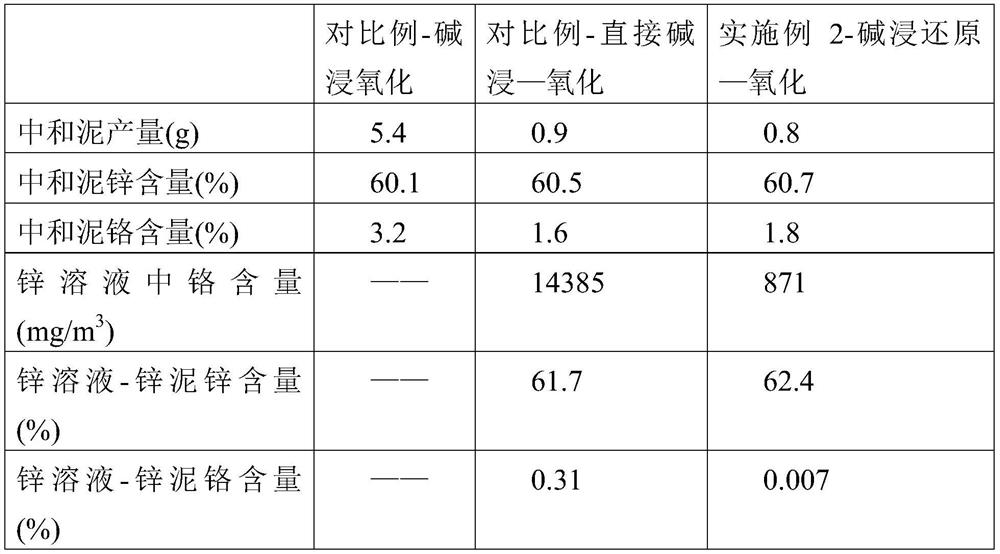

Embodiment 2

[0044] The chromium-containing sludge in a factory area contains 15% chromium, 3% zinc, 6% Cu, 2% Fe and 2% Ni. Add sulfuric acid to 100g of chromium-containing sludge to dissolve completely, the concentration of acid added is 40%, and the amount of acid added is 100g. After electrolyzing the acid-dissolved solution for 24 hours, the copper in the solution was removed, and the concentration of copper ions in the solution was 42mg / m 3 , 5.9g copper elemental substance was recovered. And use the extraction method to remove the iron in the solution, the iron ion concentration in the solution is 21mg / m 3 . After back-extracting the iron extract, a solution of ferric iron is obtained, and after reduction with excess reduced iron powder, a ferrous sulfate solution is obtained. Add 10% sodium hydroxide to the solution to adjust the pH value to 10, and filter to obtain sludge and high-salt solution. Add ferrous sulfate to the high-salt solution, adjust the pH value to 12, heat at ...

Embodiment 3

[0049] The chromium-containing sludge in a factory area contains 5% chromium, 18% zinc, 4% Cu, 1% Fe, and 1% Ni. Add sulfuric acid to 100g of chromium-containing sludge to dissolve completely, the concentration of acid added is 20%, and the amount of acid added is 200g. After electrolyzing the acid-dissolved solution for 24 hours, the copper in the solution was removed, and the concentration of copper ions in the solution was 16mg / m 3 , 3.8g copper elemental substance was recovered. And use the extraction method to remove the iron in the solution, the iron ion concentration in the solution is 24mg / m 3 . After back-extracting the iron extract, a solution of ferric iron is obtained, and after reduction with excess reduced iron powder, a ferrous sulfate solution is obtained. Add 5% sodium hydroxide to the solution to adjust the pH value to 7, and filter to obtain sludge and high-salt solution. Add ferrous sulfate to the high-salt solution, adjust the pH value to 10, heat at 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com