Method for removing fluorine in lithium battery positive electrode lixivium

A leachate and lithium battery technology, which is applied in the field of waste battery recycling, can solve the problems of poor quality of precursor products, shortening the service life of equipment, and substandard wastewater, and achieve the effect of large fluorine removal capacity, avoiding losses, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

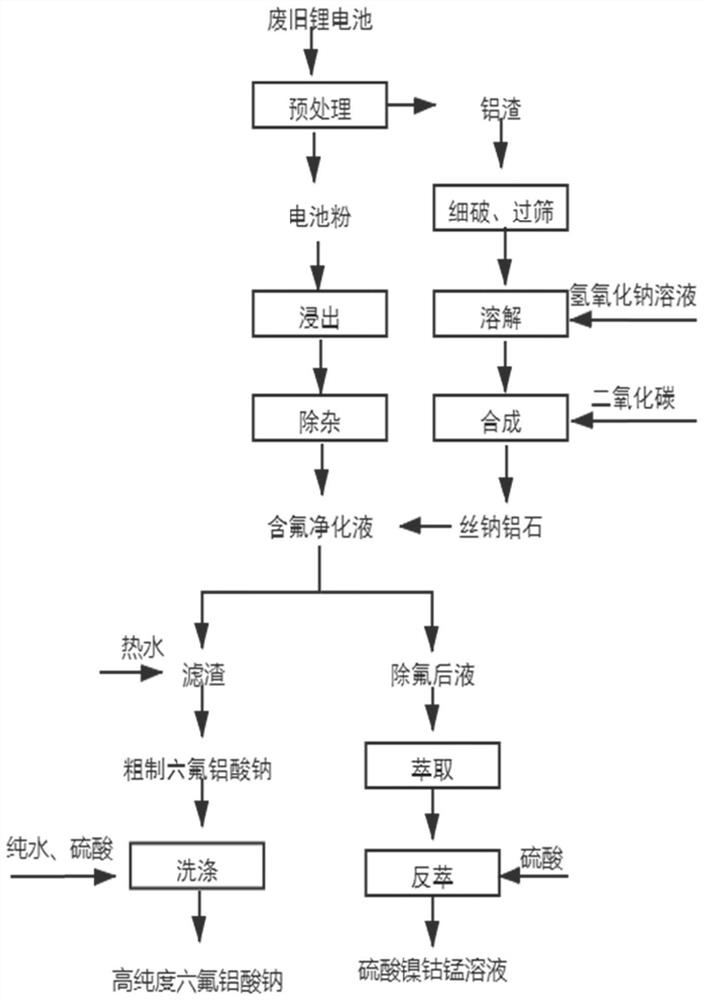

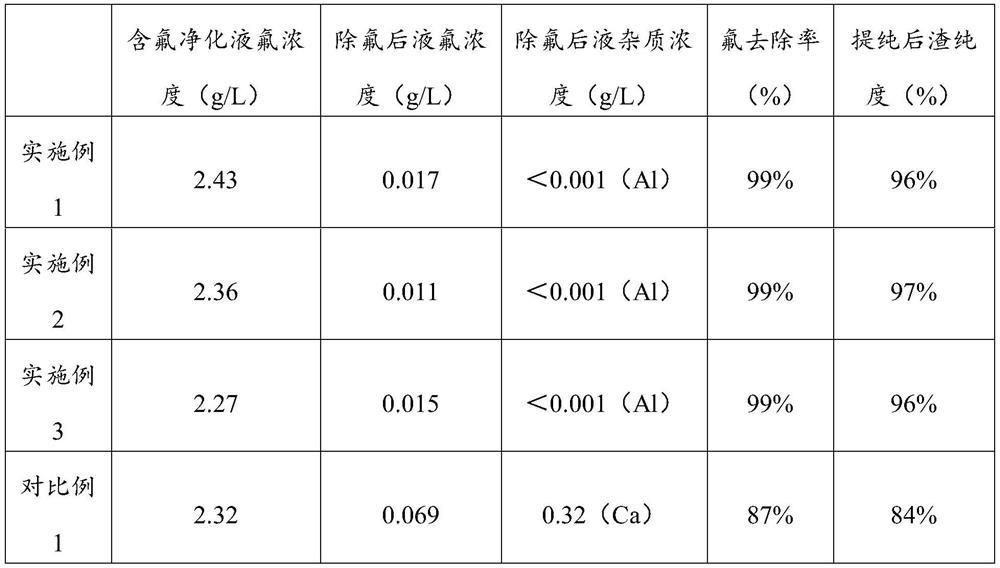

[0030] A method for removing fluorine in lithium battery cathode leaching solution, with reference to figure 1 , the specific process is:

[0031] (1) Pretreatment: disassemble, crush, sort and sieve the waste lithium battery after discharge to obtain battery powder and aluminum slag;

[0032] (2) Preparation of frasonite defluorinating agent: based on (1), after the aluminum slag is finely broken, cross a 100-mesh sieve to obtain the aluminum slag powder, and the aluminum slag powder obtained and 10% sodium hydroxide solution are mixed according to solid Liquid ratio 1: 5g / mL mixed, stirred and reacted at 80°C for 60min, after the reaction, filtered the solution to obtain insoluble slag and sodium metaaluminate solution, the insoluble slag was transferred to step (3) for acid leaching to dissolve, sodium metaaluminate The solution was fed with carbon dioxide gas, the reaction temperature was 40°C, and the stirring rate was 150rpm, until the pH in the solution was stabilized ...

Embodiment 2

[0039] A method for removing fluorine in the leach solution of the positive electrode of a lithium battery, the specific process is:

[0040] (1) Pretreatment: disassemble, crush, sort and sieve the waste lithium battery after discharge to obtain battery powder and aluminum slag;

[0041] (2) Preparation of frasonite defluorinating agent: based on (1), aluminum slag is crossed through a 100-mesh sieve after being finely broken to obtain aluminum slag powder, and the obtained aluminum slag powder is mixed with 30% sodium hydroxide solution according to solid Mix liquid ratio 1:3g / mL, stir and react at 50°C for 30min, after the reaction, filter the solution to obtain insoluble slag and sodium metaaluminate solution, transfer the insoluble slag to step (3) for acid leaching to dissolve, sodium metaaluminate The solution is fed with carbon dioxide gas, the reaction temperature is 60°C, and the stirring rate is 350rpm, until the pH in the solution is stable at 6.5, then stop stirri...

Embodiment 3

[0048] A method for removing fluorine in the leach solution of the positive electrode of a lithium battery, the specific process is:

[0049] (1) Pretreatment: disassemble, crush, sort and sieve the waste lithium battery after discharge to obtain battery powder and aluminum slag;

[0050] (2) Preparation of frasonite defluorinating agent: based on (1), after the aluminum slag is finely broken, cross a 100-mesh sieve to obtain aluminum slag powder, and the aluminum slag powder obtained and 20% sodium hydroxide solution are mixed according to solid Mix liquid ratio 1:4g / mL, stir and react at 60°C for 40min, after reaction, filter the solution to obtain insoluble slag and sodium metaaluminate solution, transfer the insoluble slag to (3) for acid leaching to dissolve, sodium metaaluminate solution Then pass in carbon dioxide gas, wherein the reaction temperature is 50°C, and the stirring rate is 200rpm, until the pH in the solution is stable at 6.0, stop stirring, age the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com