Supported solid base catalyst, preparation method and appliance thereof for compounding novel biological diesel oil

A solid base catalyst, biodiesel technology, applied in chemical instruments and methods, physical/chemical process catalysts, biofuels, etc., can solve the problems of complex post-processing process, non-reusability, low reactivity, etc., and achieve simple post-processing. , easy to recycle, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

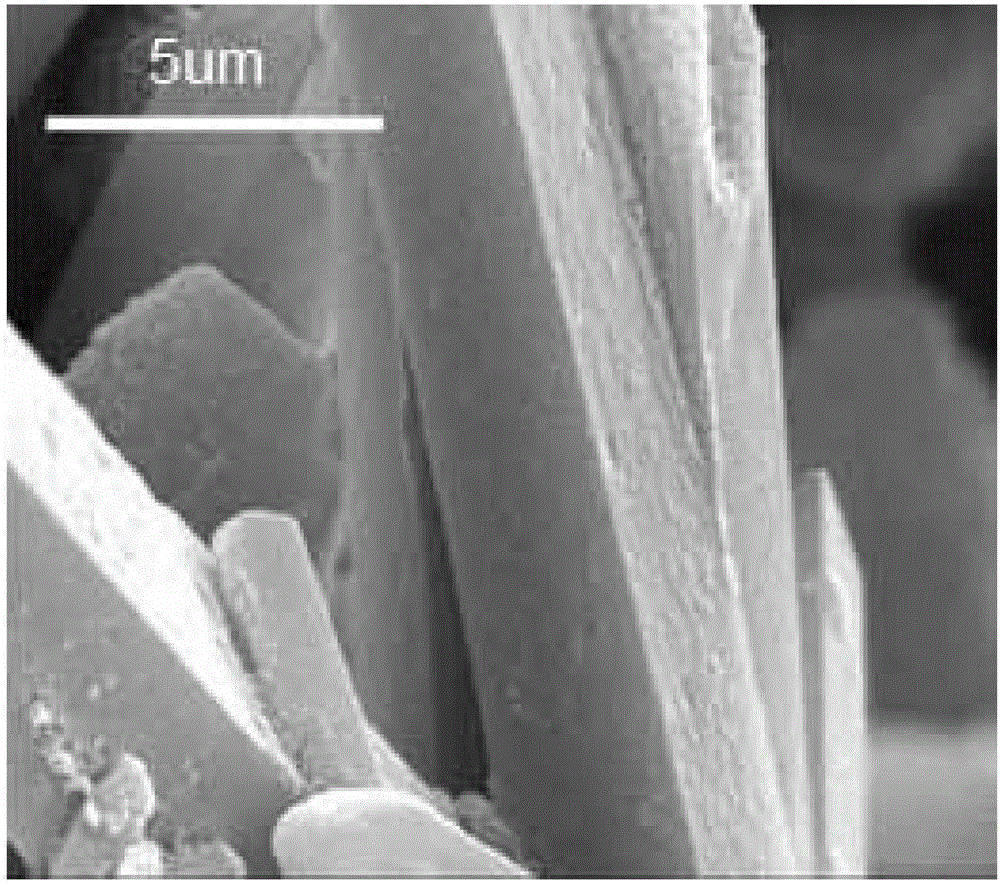

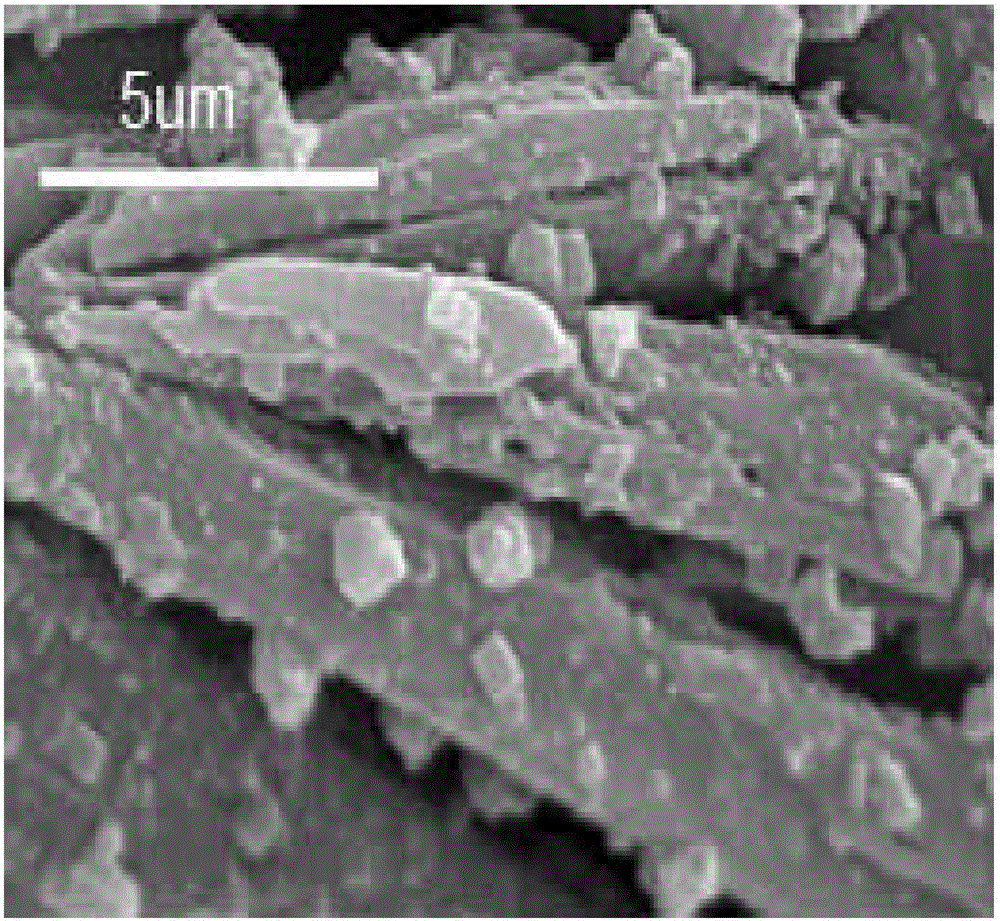

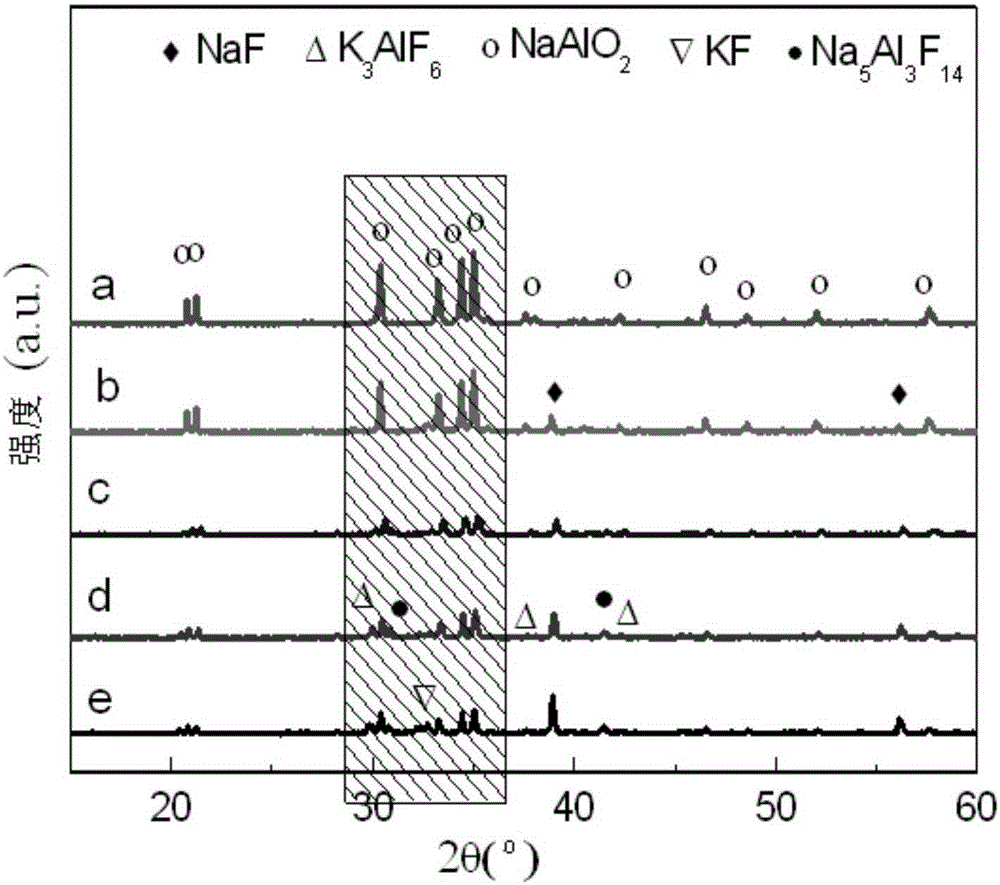

[0029] Specific embodiment one: the supported solid base catalyst of the present embodiment comprises sodium aluminate (NaAlO 2 ), potassium fluoride (KF), sodium fluoride (NaF), potassium fluoroaluminate and sodium fluoroaluminate, of which sodium aluminate (NaAlO 2 ) as the carrier, potassium fluoride (KF), sodium fluoride, potassium fluoroaluminate and sodium fluoroaluminate as loads.

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the supported solid base catalyst is recorded as x-KF / NaAlO 2 , where x represents the loading capacity of potassium fluoride on the sodium aluminate, based on the percentage of potassium fluoride in the mass of the carrier sodium aluminate, x is 10% to 70%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: the preparation method of the described supported solid base catalyst of embodiment one, carry out according to the following steps:

[0032] 1. Preparation of precursor: sodium aluminate (NaAlO 2 ) in an air atmosphere at 200-600°C for 2-6 hours; add the roasted sodium aluminate to a KF methanol solution with a mass percentage concentration of 0.63%-4.07% and stir evenly, and control the stirring speed to 100r / min-120r / min, then leave it for 4h to get the precursor;

[0033] 2. Drying and roasting: move the precursor prepared in step 1 to an oven, dry it at a temperature of 50-90°C for 12-24 hours, grind it, and finally roast it in an air atmosphere at a temperature of 200-600°C for 2-6 hours, that is A supported solid base catalyst is obtained.

[0034] The supported solid base catalyst described in this embodiment can be expressed as x-KF / NaAlO 2 , wherein x is the loading amount of potassium fluoride on sodium aluminate, based on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com