Copper alloy pipe fusion covering agent

A covering agent and copper alloy technology, applied in the field of copper smelting, can solve problems such as difficulty in satisfying high-quality copper and copper alloy products, lower copper conductivity, expensive lithium melt, etc., to achieve guaranteed composition and performance, high surface tension , to promote the effect of floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

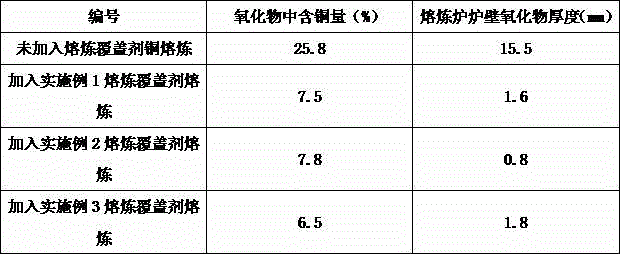

Examples

Embodiment 1

[0018] The copper alloy tube smelting covering agent in this embodiment is composed of the following components in parts by mass: 8 parts of aluminum sulfate, 5 parts of silica sand, 12 parts of calcium fluoride, 12 parts of medical stone, and 15 parts of sodium fluoroaluminate , 10 parts of bentonite, 8 parts of fluorite.

[0019] The above copper alloy tube smelting covering agent comprises the following preparation steps:

[0020] (1) Soak the above-mentioned fluorite and medical stone in 8% sulfuric acid for 8 hours, wash with deionized water, soak in 12% sodium hydroxide solution for 5 hours, wash with deionized water until neutral, and then Calcined at 550°C for 2 hours, broken into fragments with a particle size of 1-3mm;

[0021] (2) Add the aluminum sulfate, silica sand, and calcium fluoride in the above mass fractions into 1.2g / L potassium permanganate solution for soaking to remove impurities, then filter and wash to become neutral, and calcinate at 400°C for 2 hou...

Embodiment 2

[0026] The copper alloy tube smelting covering agent in this embodiment is composed of the following components in parts by mass: 16 parts of aluminum sulfate, 10 parts of silica sand, 25 parts of calcium fluoride, 20 parts of medical stone, and 26 parts of sodium fluoroaluminate , 30 parts of bentonite, 20 parts of fluorite.

[0027] The above copper alloy tube smelting covering agent comprises the following preparation steps:

[0028] (1) Soak the above-mentioned fluorite and medical stone in 12% sulfuric acid for 5 hours, wash with deionized water, soak in 10% sodium hydroxide solution for 8 hours, wash with deionized water until neutral, and then Calcined at 800°C for 2 hours, broken into fragments with a particle size of 1-3mm;

[0029] (2) Add the aluminum sulfate, silica sand, and calcium fluoride in the above mass fractions into 1.2g / L potassium permanganate solution for soaking to remove impurities, then filter and wash to become neutral, and calcinate at 400°C for 2...

Embodiment 3

[0034] The copper alloy tube smelting covering agent in this embodiment is composed of the following components in parts by mass: 12 parts of aluminum sulfate, 8 parts of silica sand, 18 parts of calcium fluoride, 16 parts of medical stone, and 20 parts of sodium fluoroaluminate , 20 parts of bentonite, 14 parts of fluorite.

[0035] The above copper alloy tube smelting covering agent comprises the following preparation steps:

[0036] (1) Soak the above-mentioned fluorite and medical stone with 10% sulfuric acid for 6 hours, wash with deionized water, then soak with 11% sodium hydroxide solution for 7 hours, then wash with deionized water until neutral, and then Calcined at 700°C for 2 hours, broken into fragments with a particle size of 1-3mm;

[0037] (2) Add the aluminum sulfate, silica sand, and calcium fluoride in the above mass fractions into 1.2g / L potassium permanganate solution for soaking to remove impurities, then filter and wash to neutral, and calcinate at 400-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com