Forging and heat treatment process of free forge piece

A free forging technology, applied in the forging field of free forgings, can solve the problems of high strength and toughness, high strength and low density, unable to meet the requirements of high strength, corrosion resistance and light weight of aluminum alloy materials, etc., to improve the tensile strength, Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]A forging and heat treatment process for free forgings, comprising the steps of:

[0030] Step S1, weighing the following raw materials by weight: Cr: 0.5%, Mg: 5.0%, Zn: 0.05%, Ti: 0.03%, Cu: 1.5%, Fe: 0.10%, slag remover: 3.5%, and the balance is Al;

[0031] Step S2: Add aluminum into the melting furnace and heat up to 700°C to melt, then heat up to 1200°C, add copper and magnesium after melting, smelt at this temperature for 30 minutes, add zinc, titanium, chromium and iron, and adjust the temperature to 1150°C , stir evenly, add slag cleaning agent after all melted, and refine for 45 minutes to obtain aluminum alloy liquid;

[0032] Step S3, heat the aluminum alloy liquid for 30 minutes after removing the slag, and then carry out casting. Control the casting temperature to 700°C, control the casting speed to 50mm / min, and the water pressure to 0.05MPa to obtain a casting, and heat the casting at 250°C for 20 hours. Carry out annealing treatment, free forging is ca...

Embodiment 2

[0040] A forging and heat treatment process for free forgings, comprising the steps of:

[0041] Step S1, weighing the following raw materials by weight: Cr: 0.6%, Mg: 5.5%, Zn: 0.08%, Ti: 0.04%, Cu: 1.6%, Fe: 0.12%, slag remover: 4.0%, and the balance is Al;

[0042] Step S2: Add aluminum into the melting furnace and heat up to 700°C to melt, then heat up to 1200°C, add copper and magnesium after melting, smelt at this temperature for 30 minutes, add zinc, titanium, chromium and iron, and adjust the temperature to 1150°C , stir evenly, add slag cleaning agent after all melted, and refine for 45 minutes to obtain aluminum alloy liquid;

[0043] Step S3, heat the aluminum alloy liquid for 30 minutes after removing the slag, and then carry out casting. Control the casting temperature to 700°C, control the casting speed to 50mm / min, and the water pressure to 0.05MPa to obtain a casting, and heat the casting at 250°C for 20 hours. Carry out annealing treatment, free forging is c...

Embodiment 3

[0047] A forging and heat treatment process for free forgings, comprising the steps of:

[0048] Step S1, weighing the following raw materials by weight: Cr: 0.8%, Mg: 7.0%, Zn: 0.08%, Ti: 0.04%, Cu: 1.8%, Fe: 0.14%, slag cleaning agent: 4.5%, and the balance is Al;

[0049] Step S2: Add aluminum into the melting furnace and heat up to 700°C to melt, then heat up to 1200°C, add copper and magnesium after melting, smelt at this temperature for 30 minutes, add zinc, titanium, chromium and iron, and adjust the temperature to 1150°C , stir evenly, add slag cleaning agent after all melted, and refine for 45 minutes to obtain aluminum alloy liquid;

[0050] Step S3, heat the aluminum alloy liquid for 30 minutes after removing the slag, and then carry out casting. Control the casting temperature to 700°C, control the casting speed to 50mm / min, and the water pressure to 0.05MPa to obtain a casting, and heat the casting at 250°C for 20 hours. Carry out annealing treatment, free forgi...

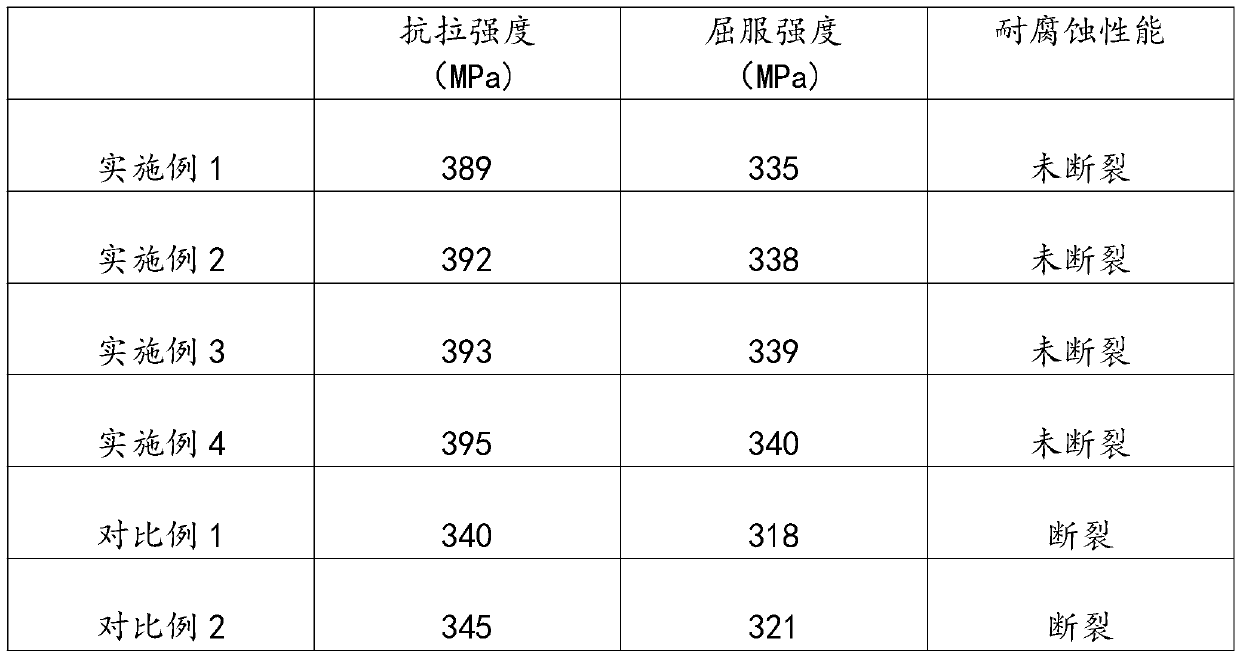

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com