High-molecular polymer foaming material as well as preparation method and application thereof

A technology of high molecular polymer and foaming materials, applied in the field of foaming materials, can solve the problems of limited application, single pore size, enhanced friction and wear, etc., to achieve the effects of wide adaptability, easy access, and increased diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a kind of preparation method of polymer foam material, comprises the following steps:

[0040] The high molecular polymer powder is cold pressed and then sintered to obtain a porous polymer;

[0041] The porous polymer was subjected to supercritical CO 2 foaming to obtain a high molecular polymer foam material.

[0042] In the invention, the high molecular polymer powder is cold-pressed and then sintered to obtain a porous polymer. In the present invention, the high molecular polymer preferably includes polyphenylene sulfide, polysulfone, polymethyl methacrylate, polytetrafluoroethylene, polycarbonate, polystyrene or polyetherimide.

[0043]In the present invention, the high molecular polymer powder is preferably dried and sieved before cold pressing; the present invention has no special requirements on the aperture of the sieved, it can be selected according to the specific high molecular polymer type, In a specific embodiment of the present i...

Embodiment 1

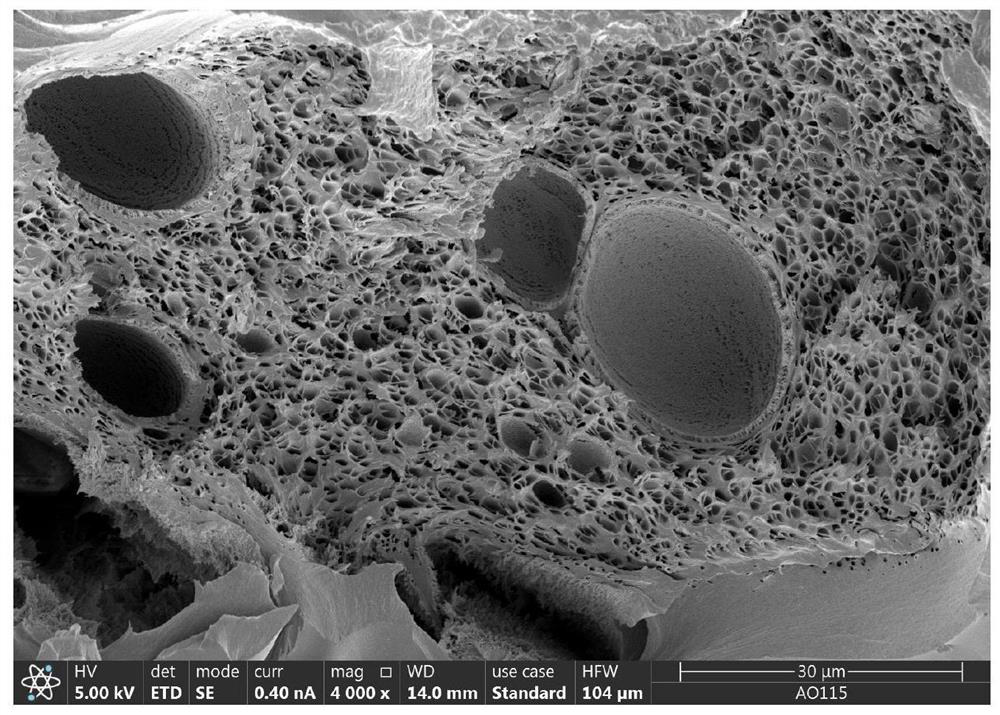

[0056] (1) Put the polyetherimide powder with a particle size of 130-180 μm after drying into the mold, and press it into a sheet-like solid in a flat vulcanizer at 5 MPa and room temperature for 30 minutes. Then put it into a sintering furnace and sinter at 300°C for 2.5h to obtain a porous polyetherimide (referred to as porous PEI), which was subjected to mercury intrusion analysis. The results showed that the average pore diameter of the obtained porous PEI was 9.6 microns, and the porosity 20%.

[0057] At the same time, a solid non-porous PEI sheet was prepared for comparison. The preparation method was as follows: the PEI powder was put into a mold, sintered at 280° C. and 10 MPa, and cooled to obtain a solid non-porous PEI.

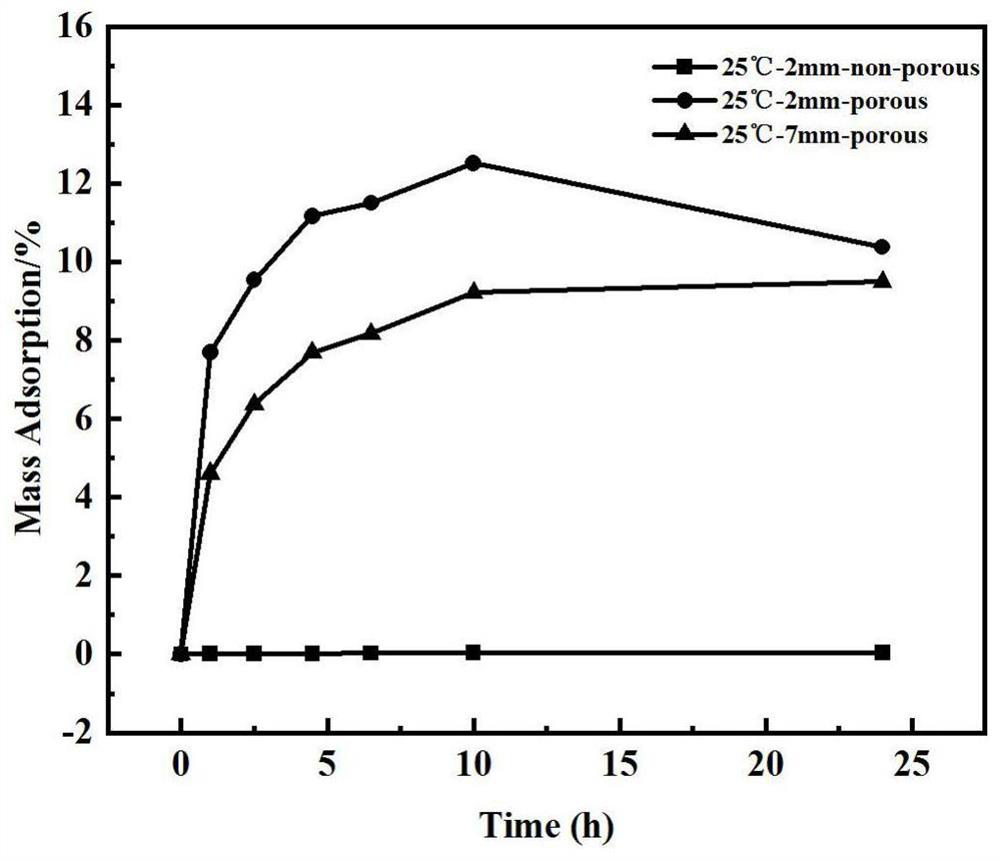

[0058] (2) Cut the obtained porous PEI into 2mm and 7mm thin slices, which are recorded as 2mm-porous and 7mm-porous respectively, and cut the solid non-porous PEI into 2mm sheets, which are recorded as 2mm-non-porous, and put them into high pressu...

Embodiment 2

[0066] Steps (1)~(3) are identical with embodiment 1, and steps (4)~(5) are as follows:

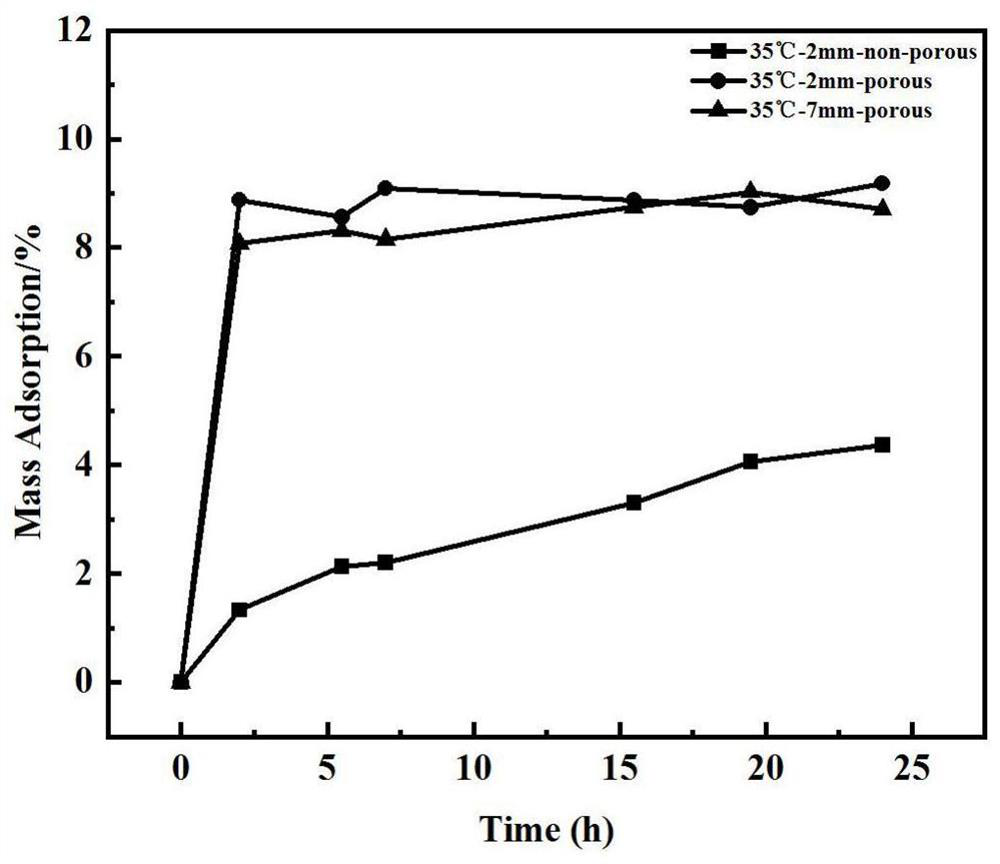

[0067] (4) Set the foaming condition to 35°C, 15MPa, under which conditions 2mm-porous, 7mm-porous and 2mm-non-porous are subjected to supercritical CO 2 Adsorption, take out at intervals, weigh and calculate CO of different PEI samples 2 Adsorption capacity, the calculation formula is shown in formula I, CO at different times 2 The adsorption capacity as image 3 shown;

[0068] according to image 3 It can be seen that compared with Example 1, the temperature of this example is higher, CO 2 The diffusion rate is faster, the CO of 2mm porous material PEI and 7mm porous PEI 2 At the same time, the adsorption capacity reached the highest value rapidly, but due to the increase in temperature, the CO 2 The density decreases, so the highest adsorption capacity is about 9.2%; and the adsorption capacity of porous PEI is much higher than that of solid PEI.

[0069] (5) When CO 2 When the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com