Biomass nanomaterial porous microsphere and preparation method thereof

A technology of nanomaterials and porous microspheres, applied in separation methods, chemical instruments and methods, filter regeneration, etc., can solve problems such as difficult recycling, low utilization efficiency of nanomaterials, secondary pollution, etc., and achieve efficient adsorption and degradation , the implementation scheme is simple and easy, and the effect of high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Stir and pulverize 10g of pulp, soak in 400mL of 4.5wt% sodium hydroxide solution for 36h; disperse the obtained pretreated cellulose in 400mL of deionized water, add 3g of potassium permanganate, and at the same time add 1.5g of oxalic acid, add 36mL of concentrated sulfuric acid, Stirring and reacting at 55° C. for 12 h, washing the obtained precipitate repeatedly until the supernatant becomes turbid when washing the precipitate, and obtaining a suspension of cellulose nanocrystals loaded with manganese dioxide.

[0044] Take 80g of manganese dioxide-loaded cellulose nanocrystal suspension, add 2g of nano-titanium dioxide and 10g of sodium alginate, and stir at 40°C. Add 0.1g of sodium dodecylbenzenesulfonate, and continue stirring and foaming for 30min at 10000rpm / min.

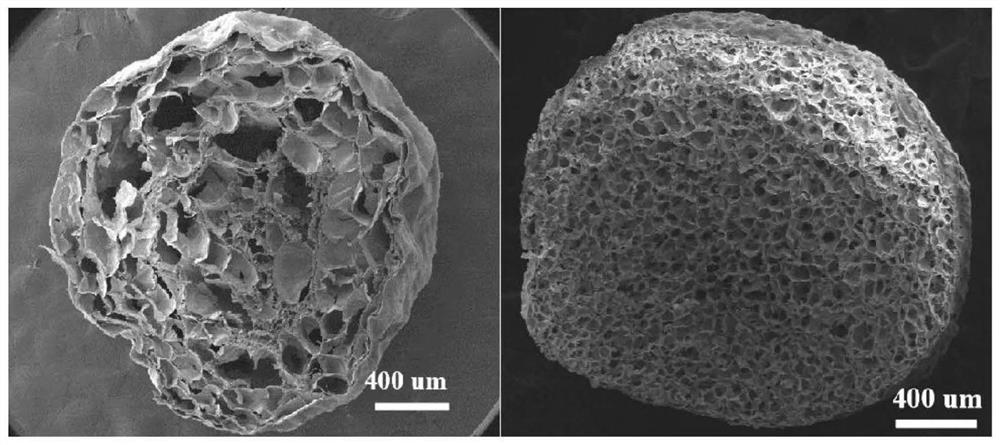

[0045] After foaming, it was dripped into Ca with a mass fraction of 15%. 2+ solution, prepared into a hydrogel, and then freeze-dried. Take 100 mg of porous microspheres and add them to 30 ml of m...

Embodiment 2

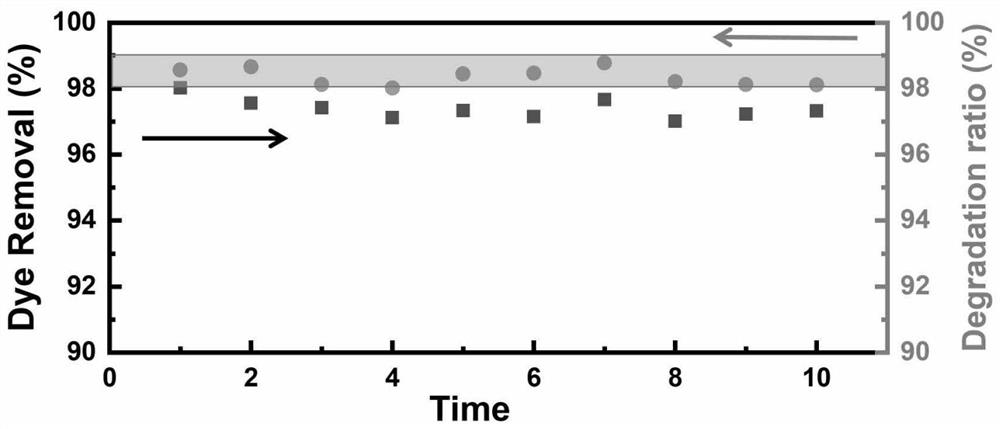

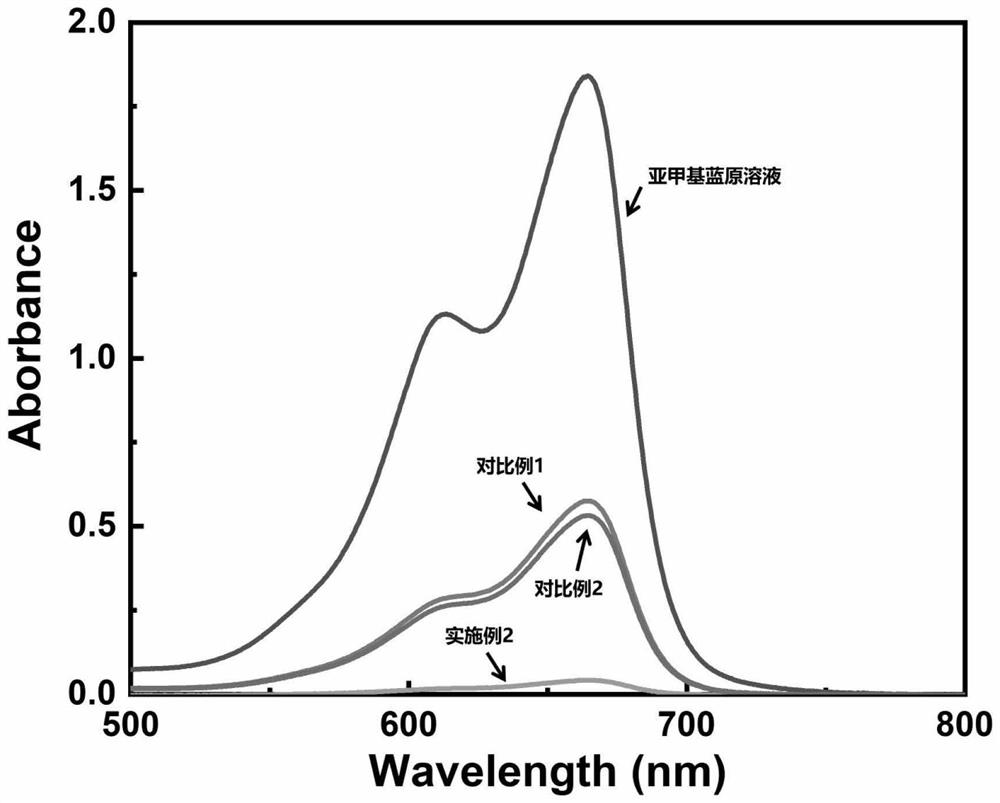

[0049] The sodium dodecylbenzene sulfonate add-on is 3g, and all the other conditions (such as: raw material type, consumption and technological process etc.) are all the same with embodiment 1.

[0050] The prepared cellulose nanocrystal / nano-manganese dioxide / nano-titanium dioxide / sodium alginate emulsion has large appearance, low density and light brown color. The prepared porous microsphere has a small and compact pore structure, and the pore size distribution is uniform. Using the BET test, the specific surface area is 11m 2 / g, the adsorption capacity to methylene blue is 306.4mg / g, and the degradation rate is 97.9%. The porous microspheres are cyclically regenerated, and after repeated adsorption and degradation ten times, the initial adsorption and degradation performance is still maintained.

Embodiment 3

[0052] The addition amount of sodium alginate is 5g, and all the other conditions (such as: raw material type, consumption and technological process etc.) are all the same with embodiment 1.

[0053] Using the BET test, the specific surface area is 9m 2 / g, the adsorption capacity to methylene blue is 225.4mg / g, and the degradation rate is 87.1%. The porous microspheres are cyclically regenerated, and after repeated adsorption and degradation ten times, the initial adsorption and degradation performance is still maintained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com