Porous sound absorption material and processing method thereof

A technology of porous sound absorption and processing method, which is applied to chemical instruments and methods, synthetic resin layered products, layered products, etc. Excellent mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

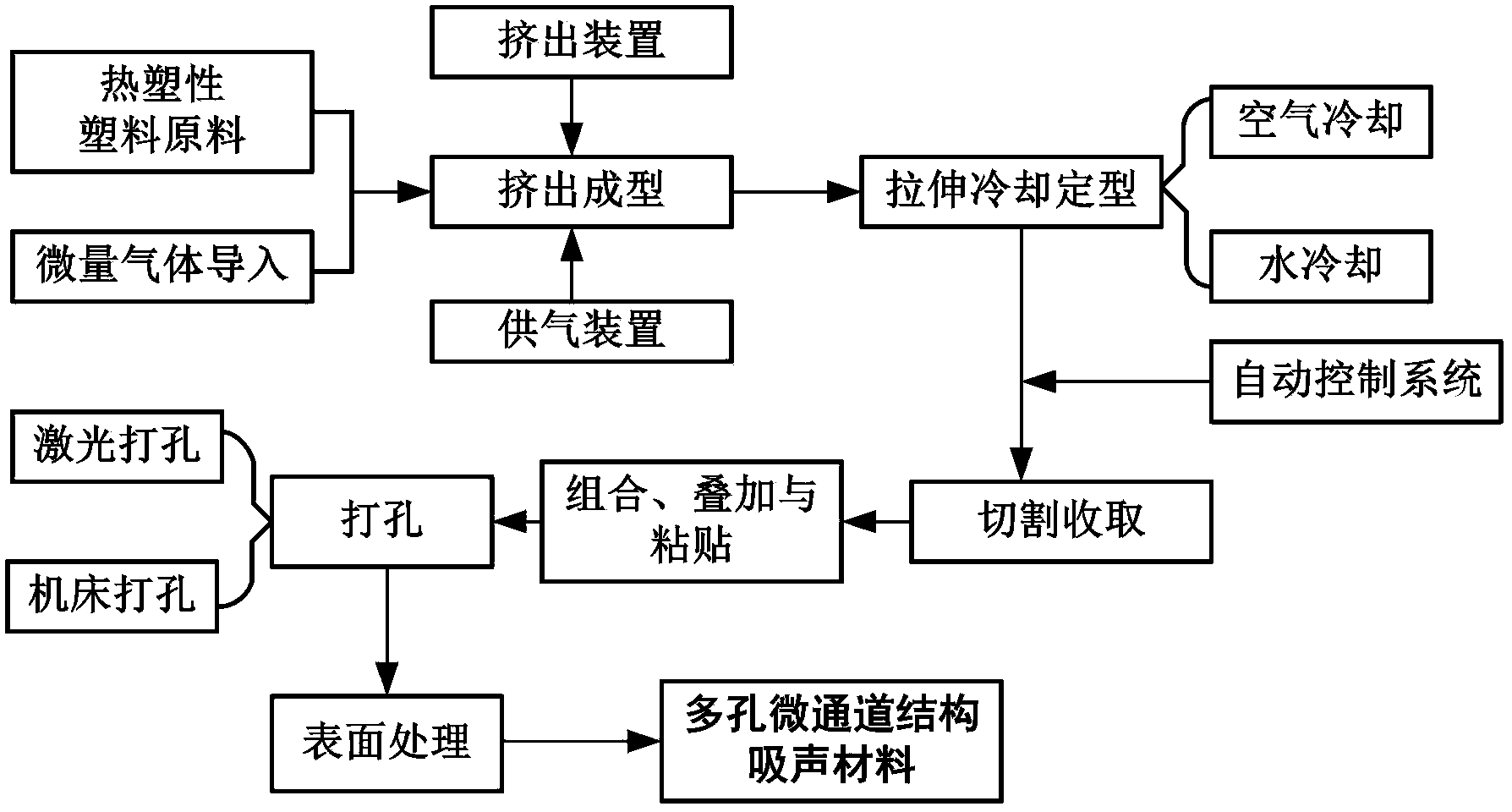

Method used

Image

Examples

Embodiment 1

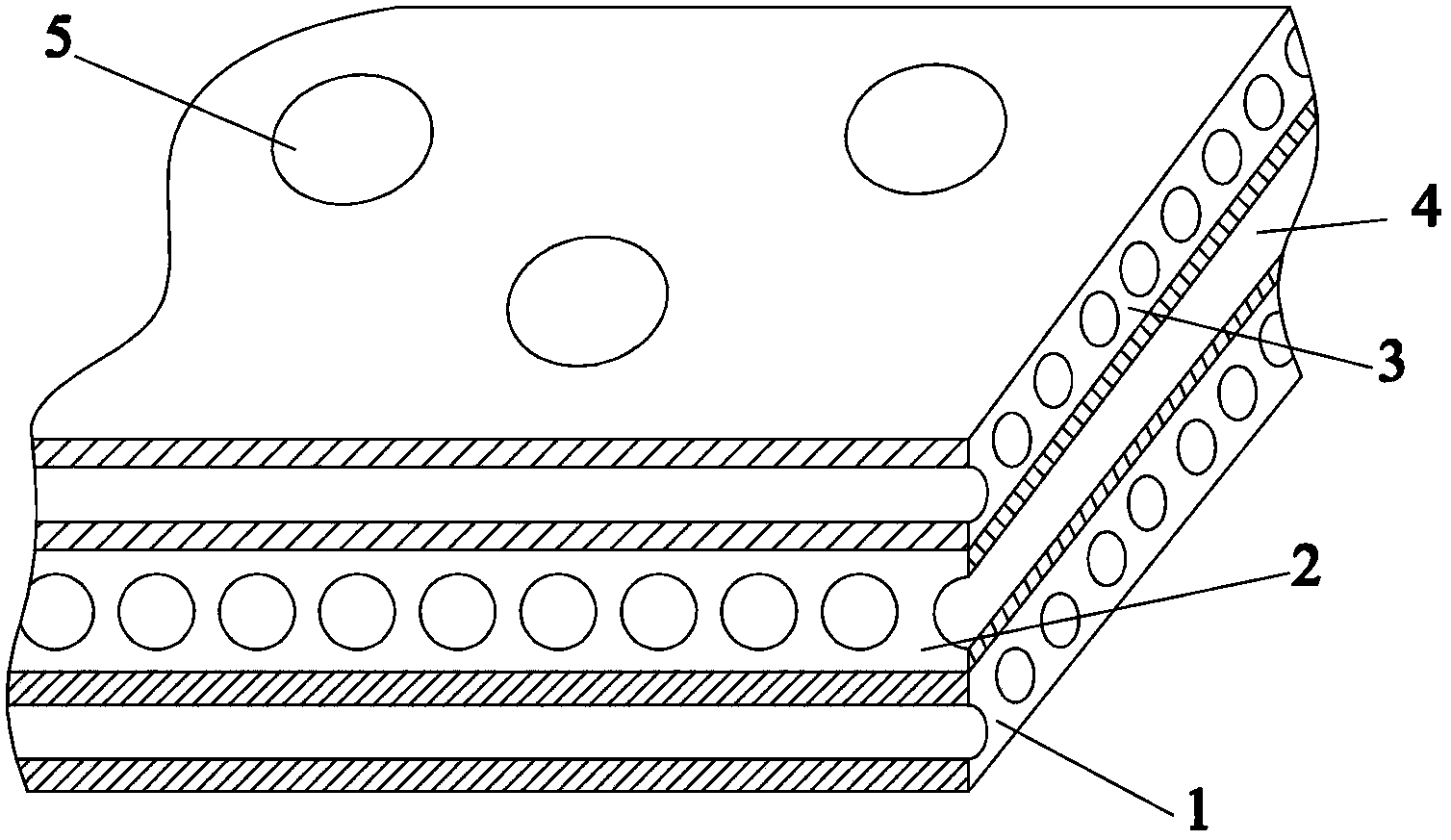

[0037] 1) The microchannel sheet is processed by the microchannel sheet extrusion device. The device is composed of an extrusion device and an air supply device: the extrusion device is used to plasticize the polymer raw material, shape the cross section, cool and shape and roll; The air supply device provides air of different pressures, which is connected with the injection core in the extruder head to adjust the deformation of the cross-section of the microchannel;

[0038] 2) The temperature of the heating section of the screw extruder: zone 1: 180°C, zone 2: 190°C, zone 3: 190°C, zone 4: 180°C. Screw speed: 0-20r / min, the basic clearance of multi-microchannel sheet extrusion die is 1.6mm;

[0039] 3) The parameters of the extruded microchannel sheet are: the length of the sheet is 30 mm, the thickness is 1.2 mm, the horizontal length of the microchannel cross section is 400 μm, and the vertical length is 350 μm; the average hydraulic diameter of the microchannel is 385 μm....

Embodiment 2

[0046] 1) The microchannel sheet is processed by the microchannel structure extrusion device. The device is composed of an extrusion device and an air supply device: the extrusion device is used to plasticize the polymer raw material, shape the cross section, cool and shape and roll; The air device provides air with different pressures, which is connected with the injection core in the extruder head to adjust the deformation of the cross-section of the microchannel;

[0047] 2) The temperature of the heating section of the screw extruder: zone 1: 180°C, zone 2: 190°C, zone 3: 190°C, zone 4: 180°C. Screw speed: 0-20r / min, the basic clearance of multi-microchannel sheet extrusion die is 1.6mm;

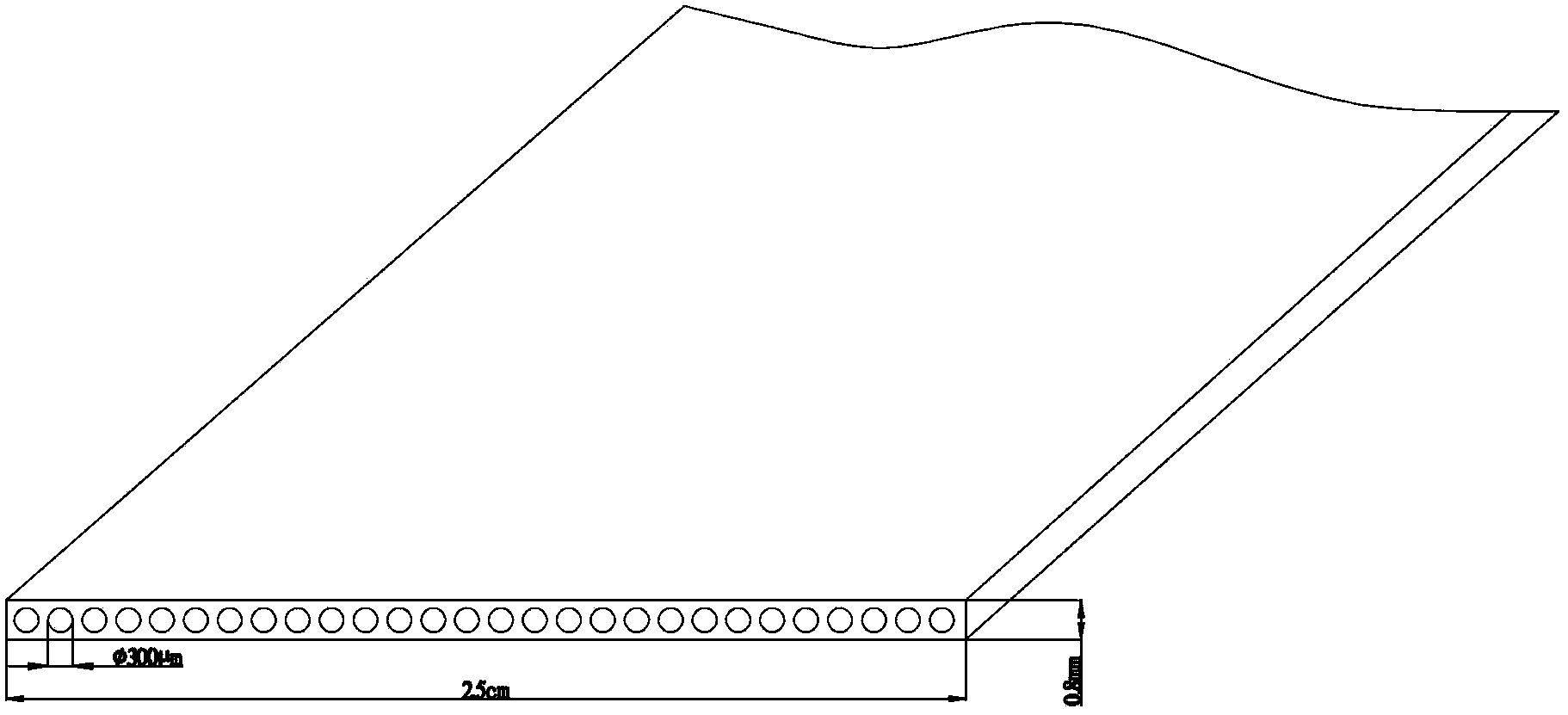

[0048] 3) The parameters of the extruded microchannel sheet are: the length of the sheet is 30 mm, the thickness is 0.8 mm, the horizontal length of the microchannel cross section is 120 μm, and the vertical length is 100 μm; the average hydraulic diameter of the microchannel is 113 μm. ...

Embodiment 3

[0056] 1) The microchannel sheet is processed by the microchannel structure extrusion device. The device is composed of an extrusion device and an air supply device: the extrusion device is used to plasticize the polymer raw material, shape the cross section, cool and shape and roll; The air device provides air with different pressures, which is connected with the injection core in the extruder head to adjust the deformation of the cross-section of the microchannel;

[0057] 2) The temperature of the heating section of the screw extruder: zone 1: 180°C, zone 2: 190°C, zone 3: 190°C, zone 4: 180°C. Screw speed: 0-20r / min, the basic clearance of multi-microchannel sheet extrusion die is 1.6mm;

[0058] 3) The parameters of the extruded microchannel sheet are: the sheet length is 30 mm, the thickness is 1.0 mm, the horizontal length of the cross-section of the microchannel is 300 μm, and the vertical length is 200 μm; the average hydraulic diameter of the microchannel is 255 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com