Device for preparing rich oxygen from air through magnetic-method multi-radial separation

A technology for air separation and magnetic separation, applied in magnetic separation, solid separation, oxygen preparation, etc., can solve the problems of large floor space and low oxygen enrichment efficiency, reduce floor space, reduce oxygen production cost, and improve separation effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

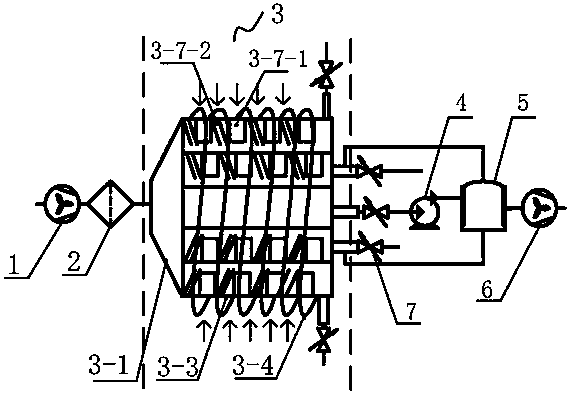

[0024] Specific implementation mode 1: see figure 1 Illustrating this embodiment, a device for producing oxygen-enriched air by magnetic multi-radial separation of air described in this embodiment includes an air blower 1, an air filter 2 and a multi-layer magnetic separation mechanism 3;

[0025] The air blower 1 pumps the air into the air filter 2, and after being filtered by the air filter 2, it enters the multi-layer magnetic separation zone in the multi-layer magnetic separation mechanism 3. The multi-layer magnetic separation zone makes the oxygen in the air in the electromagnetic field and Under the combined action of the gradient magnetic field generated by the permanent magnets, the outermost magnetic separation zone enters the innermost magnetic separation zone in turn, and the oxygen concentration increases layer by layer to realize the separation of oxygen and complete the preparation of oxygen enrichment.

[0026] In this embodiment, when the oxygen-enriched conce...

specific Embodiment approach 2

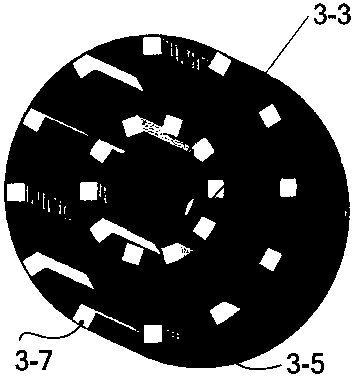

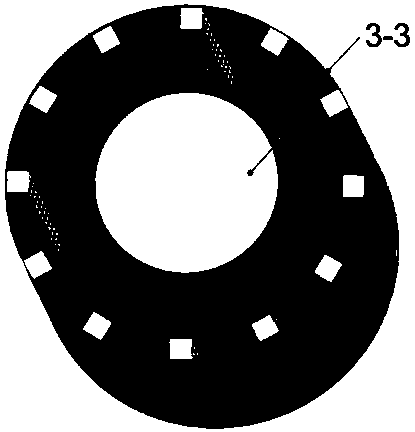

[0031] Specific implementation two: see Figure 1 to Figure 3 Describing this embodiment, the difference between this embodiment and the device for producing oxygen-enriched air by magnetic multi-radial separation described in Embodiment 1 is that the multi-layer magnetic separation mechanism 3 includes a buffer cover 3-1, a sealing cover 3-2, the sleeve unit 3-3 and the coil 3-4;

[0032] The sleeve unit 3-3 is composed of a plurality of coaxial sleeves that are nested in each other, and a layer of annular cavity is formed between any two adjacent sleeves. The annular cavity is a layer of magnetic separation area. The annular cavity of the layer and the cylindrical cavity 3-8 formed by the innermost sleeve constitute a multi-layer magnetic separation zone, wherein the annular cavity of the outermost layer is the nitrogen separation zone 3-5, and the remaining annular cavities and The cylindrical cavity 3-8 constitutes an oxygen-enriched separation zone 3-6;

[0033] The sea...

specific Embodiment approach 3

[0038] Specific implementation three: see Figure 1 to Figure 3 Illustrating this embodiment, the difference between this embodiment and the device for producing oxygen-enriched oxygen by magnetic multi-radial separation of air described in Embodiment 2 is that the inner wall of the sleeve in each layer of the magnetic separation zone is provided with steel The wool 3-7-2, the steel wool 3-7-2, the permanent magnet magnet group 3-7 and the coil 3-4 work together to change the magnetic field gradient in the magnetic separation zone.

[0039] In this embodiment, a magnetic field with radial gradient changes is formed around the permanent magnet magnet group 3-7. After the coil 3-4 is energized, a magnetic field with radial gradient changes is formed around it. The steel wool 3-7-2 acts to strengthen the magnetic field gradient. At the same time, a radial gradient magnetic field will also be formed. The radial magnetic field strengths generated by the three are superimposed, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com